High-stability emulsion explosive for smooth blasting and preparation method of emulsion explosive

An emulsion explosive, smooth blasting technology, applied in explosives, non-explosive/non-thermal components, offensive equipment, etc., can solve problems such as stagnation and complex composition of new explosives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

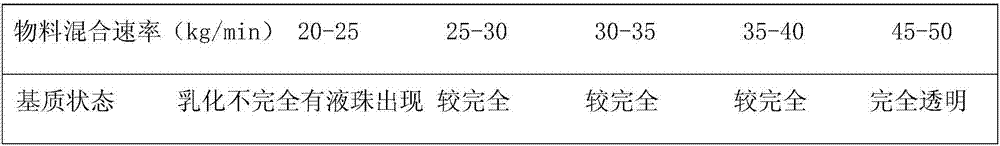

Method used

Image

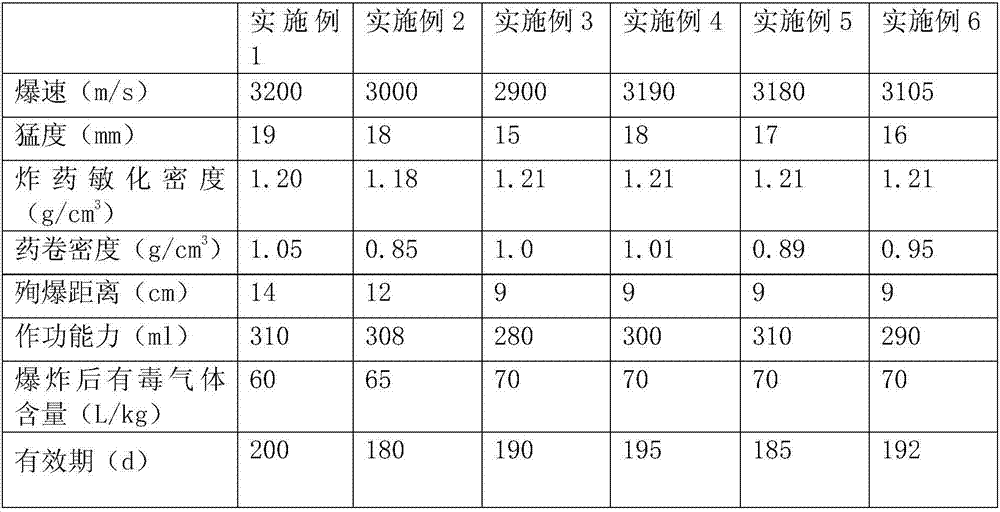

Examples

Embodiment 1

[0053] This embodiment provides an emulsion explosive for high-stability smooth blasting. The emulsion explosive includes the following components in parts by mass:

[0054] Solid amine nitrate: 30 parts, sodium nitrate: 7 parts, methylamine nitrate: 10 parts, aluminum powder: 8 parts, water: 7 parts, density regulator: 7 parts, stearic acid: 5 parts, crosslinking agent: 4 Parts, foaming cream: 1 part, composite emulsifier: 2 parts, sensitizer: 5 parts, pentaerythritol tetranitrate: 0.5 part.

[0055] The density regulator is a mixture of glass microspheres, expanded perlite and hollow plastic balls. The glass microbeads are calculated by mass ratio: expanded perlite: hollow plastic balls = 2:1:1; the crosslinking agent is borax The composite emulsifier is composed of modified soybean phospholipid, high-viscosity emulsifier Span-80 and polyolefin derivative (LR-1); the sensitizer is sodium nitrite.

[0056] The compound emulsifier is calculated by mass parts, modified soybean phosph...

Embodiment 2

[0066] This embodiment provides an emulsion explosive for high-stability smooth blasting. The emulsion explosive includes the following components in parts by mass:

[0067] Solid amine nitrate: 40 parts, sodium nitrate: 9 parts, methylamine nitrate: 13 parts, aluminum powder: 10 parts, water: 11 parts, density regulator: 9 parts, stearic acid: 7 parts, crosslinking agent: 6 Parts, foaming cream: 3 parts, composite emulsifier: 4 parts, sensitizer: 7 parts, pentaerythritol tetranitrate: 1 part.

[0068] The density regulator is a mixture of glass microspheres, expanded perlite and hollow plastic balls. The glass microbeads are calculated by mass ratio: expanded perlite: hollow plastic balls = 2:1:1; the crosslinking agent is borax The combination of potassium tartrate; the composite emulsifier is composed of modified soybean phospholipid, high-viscosity emulsifier Span-80 and polyolefin derivative LR-1; the sensitizer is sodium nitrite.

[0069] The compound emulsifier is calculated ...

Embodiment 3

[0079] This embodiment provides an emulsion explosive for high-stability smooth blasting. The emulsion explosive includes the following components in parts by mass:

[0080] Solid ammonium nitrate: 35 parts, sodium nitrate: 8 parts, methylamine nitrate: 11 parts, aluminum powder: 9 parts, water: 9 parts, density regulator: 8 parts, stearic acid: 6 parts, crosslinking agent: 5 Parts, reducing agent: 2 parts, foaming cream: 2 parts, composite emulsifier: 3 parts, sensitizer: 6 parts, pentaerythritol tetranitrate: 0.8 parts.

[0081] The density modifier is a mixture of glass beads, expanded perlite and hollow plastic balls. The glass beads are calculated by mass ratio: expanded perlite: hollow plastic balls = 2:1:1; the crosslinking agent is tartaric acid Potassium acid; composite emulsifier is composed of modified soybean phospholipid, high viscosity emulsifier Span-80 and polyolefin derivative (LR-1); sensitizer is sodium nitrite.

[0082] The compound emulsifier is calculated in pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com