Sensitization method of deep hole blasting emulsion explosive

A technology of emulsion explosives and deep hole blasting, which is applied in the field of sensitization of emulsion explosives in deep hole blasting. It can solve the problem of mechanical mixtures that cannot achieve the best density, dispersion, and water content. Bulk emulsion explosives are easy to scatter and destroy the material composition of explosives. and other problems, to achieve the effect of simple production process operation process, excellent explosive performance, and no increase in detonator sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

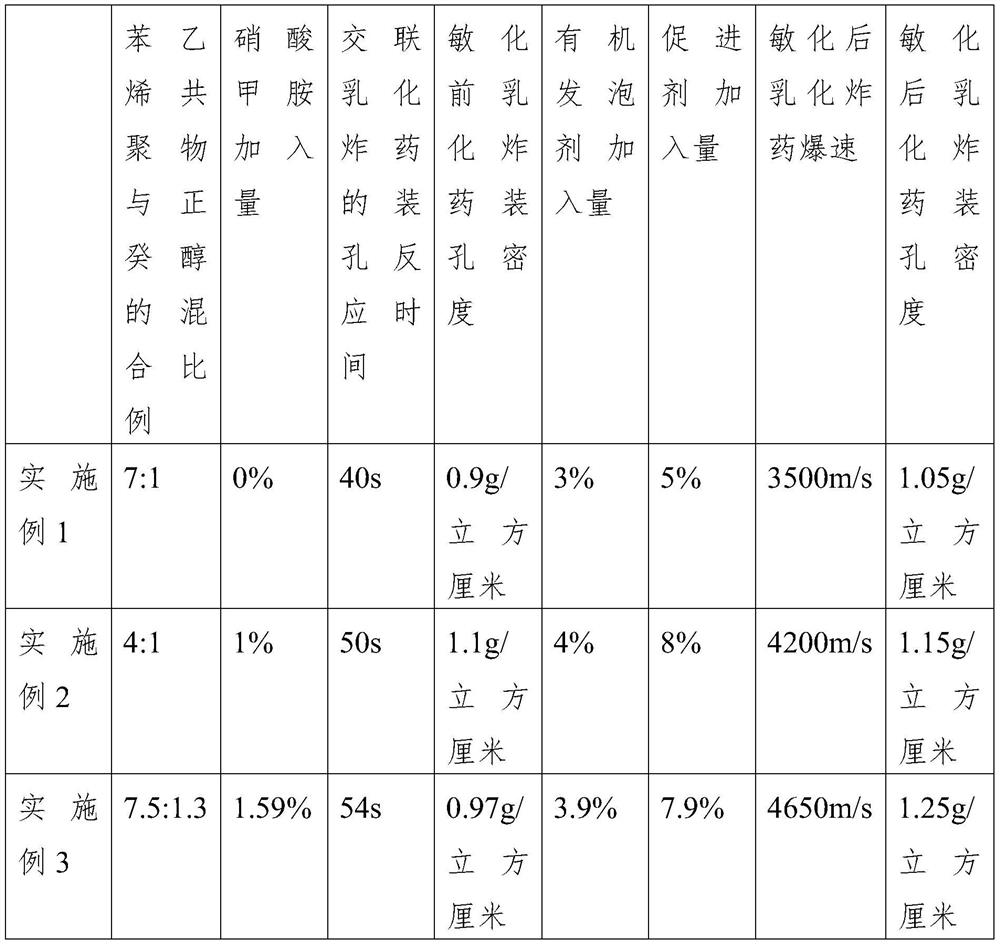

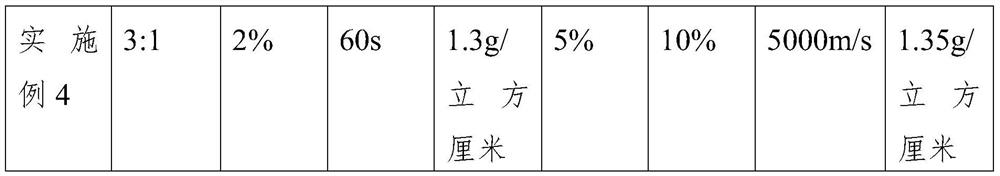

Examples

Embodiment 1

[0039] The invention provides a method for sensitizing emulsion explosives for deep hole blasting, the specific steps are as follows:

[0040] Step 1: Preparation of the aqueous phase:

[0041] a. Transport ammonium nitrate, sodium nitrate and flame suppressant to the crusher in a ratio of 6:1:1 for crushing;

[0042] b. Conveying the metered crushed ammonium nitrate, sodium nitrate and flame suppressant into the water phase preparation tank;

[0043] c. According to the amount of ammonium nitrate, sodium nitrate and flame extinguishing agent input, a certain amount of water is added to the aqueous phase preparation tank, and concentrated ammonia water is added to adjust the pH value of the mixed liquid to 4;

[0044] d. Use a steam boiler to heat up to 105.3°C to dissolve the material;

[0045] e. Transport the material to the water phase storage tank for heat preservation and standby, which is the water phase;

[0046] Step 2: Preparation of the oil phase:

[0047] a. Mi...

Embodiment 2

[0061] The invention provides a method for sensitizing emulsion explosives for deep hole blasting, the specific steps are as follows:

[0062] Step 1: Preparation of the aqueous phase:

[0063] a. Transport ammonium nitrate, sodium nitrate and flame suppressant to the crusher in the ratio of 7:1.5:1.5 for crushing;

[0064] b. Conveying the metered crushed ammonium nitrate, sodium nitrate and flame suppressant into the water phase preparation tank;

[0065] c. According to the amount of ammonium nitrate, sodium nitrate and flame extinguishing agent input, a certain amount of water is added to the aqueous phase preparation tank, and concentrated ammonia water is added to adjust the pH value of the mixed liquid to 5;

[0066] d. Use a steam boiler to heat up to 106.8°C to dissolve the material;

[0067] e. Transport the material to the water phase storage tank for heat preservation and standby, which is the water phase;

[0068] Step 2: Preparation of the oil phase:

[0069]...

Embodiment 3

[0083] The invention provides a method for sensitizing emulsion explosives for deep hole blasting, the specific steps are as follows:

[0084] Step 1: Preparation of the aqueous phase:

[0085] a. Transport ammonium nitrate, sodium nitrate and flame suppressant to the crusher for crushing at a ratio of 6.5:1.25:1.25;

[0086] b. Conveying the metered crushed ammonium nitrate, sodium nitrate and flame suppressant into the water phase preparation tank;

[0087] c. According to the amount of ammonium nitrate, sodium nitrate and flame suppressant put in, add a certain amount of water to the water phase preparation tank, add concentrated ammonia water to adjust the pH value of the mixed liquid to 5.5;

[0088] d. Use a steam boiler to heat up to 106.7°C to dissolve the material;

[0089] e. Transport the material to the water phase storage tank for heat preservation and standby, which is the water phase;

[0090] Step 2: Preparation of the oil phase:

[0091] a. Mix the styrene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com