Method for preparing high-quality pentaerythritol oleate

A technology for pentaerythritol oleate and pentaerythritol, which is applied in the field of preparing high-quality pentaerythritol oleate, can solve the problems of shortening the service life of machinery, no method reported in literature, accelerated loss of mechanical lubrication system, etc., and achieves easy realization and simple and convenient operation. , the effect of high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

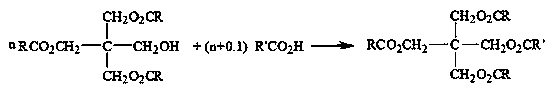

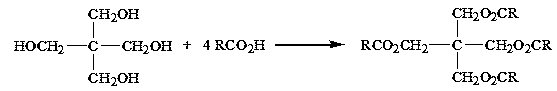

Method used

Image

Examples

Embodiment 1

[0026] Add 68.1g (0.5mol) of pentaerythritol, 557.9g (1.975mol) of oleic acid in the reactor successively, add p-toluenesulfonic acid accounting for 5‰ of the mass fraction of oleic acid as catalyst, and toluene as water-carrying agent, control oil bath heating Temperature 150-155°C, under the protection of nitrogen, stir and reflux, divide water for 1-1.5 hours, cool, add 4.5g acetic acid (0.075mol), pass nitrogen, heat the oil bath to 150-155°C, stir, continue to reflux and divide water 1 hour. After the reaction was complete, cool to room temperature, wash with water, and remove the toluene from the organic layer in a vacuum to obtain a light yellow oily transparent liquid with an acid value of 0.06 mgKOH / g and a yield of 98%.

Embodiment 2

[0028] In the reactor, add 68.1g (0.5mol) of pentaerythritol, 550.8g (1.95mol) of oleic acid, p-toluenesulfonic acid accounting for 5‰ of oleic acid mass fraction as a catalyst, and toluene as a water-carrying agent to control the heating temperature of the oil bath 150-155°C, under the protection of nitrogen, stir and reflux, divide water for 1-1.5 hours, cool, add 7.4g propionic acid (0.1mol), pass nitrogen, heat the oil bath to 150-155°C, stir, continue to reflux and divide water 1 hour. After the reaction was complete, cool to room temperature, wash with water, and remove the toluene from the organic layer in vacuum to obtain a light yellow oily transparent liquid with an acid value of 0.08 mgKOH / g and a yield of 98.5%.

Embodiment 3

[0030] In the reactor, add 68.1g (0.5mol) of pentaerythritol, 550.8g (1.95mol) of oleic acid, p-toluenesulfonic acid accounting for 5‰ of oleic acid mass fraction as a catalyst, and toluene as a water-carrying agent to control the heating temperature of the oil bath 150-155°C, under the protection of nitrogen, stir and reflux, divide water for 1-1.5 hours, cool, add 8.8g butyric acid (0.1mol), pass nitrogen, heat the oil bath to 150-155°C, stir, continue to reflux and divide water 1 hour. After the reaction is complete, cool to room temperature, wash with water, heat the organic layer to 60-80°C, add 20g of activated clay, stir for 0.5h, remove the toluene in vacuum after suction filtration, and obtain a light yellow oily transparent liquid with an acid value of 0.05mgKOH / g. The rate is 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com