Detonation preparation method for alumina-adhered diamond nano composite particle material

A diamond particle and nano-composite technology, which is applied in the field of explosive processing, can solve the problems of compounding, difficult nano-alumina and nano-diamond, and achieve the effects of low cost, simple preparation method and good particle dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Add 1 g of boric acid to 30 ml of distilled water, add 5 g of nano-diamonds to the boric acid solution, mix evenly by ultrasonic, then heat and dry at 100°C.

[0022] (2) Put the boric acid diamond into a heat treatment furnace, and calcinate at 400°C to 450°C for half an hour to boride the surface of the diamond particles, then wash with distilled water several times to remove excess boric acid, and dry at 100°C.

[0023] (3) Weigh 18g of aluminum nitrate and dissolve it in 100ml of distilled water, add borated nano-diamonds, and disperse by ultrasonic.

[0024] (4) Add ammonia water dropwise to the aluminum nitrate solution until the aluminum is completely precipitated, then add 0.1 mol / L hydrochloric acid to the solution to adjust the pH value to 3-4, and let it age for 30 hours.

[0025] (5) Filter out the mixed sediment, heat and dry at 100-150°C, and pulverize to obtain powder;

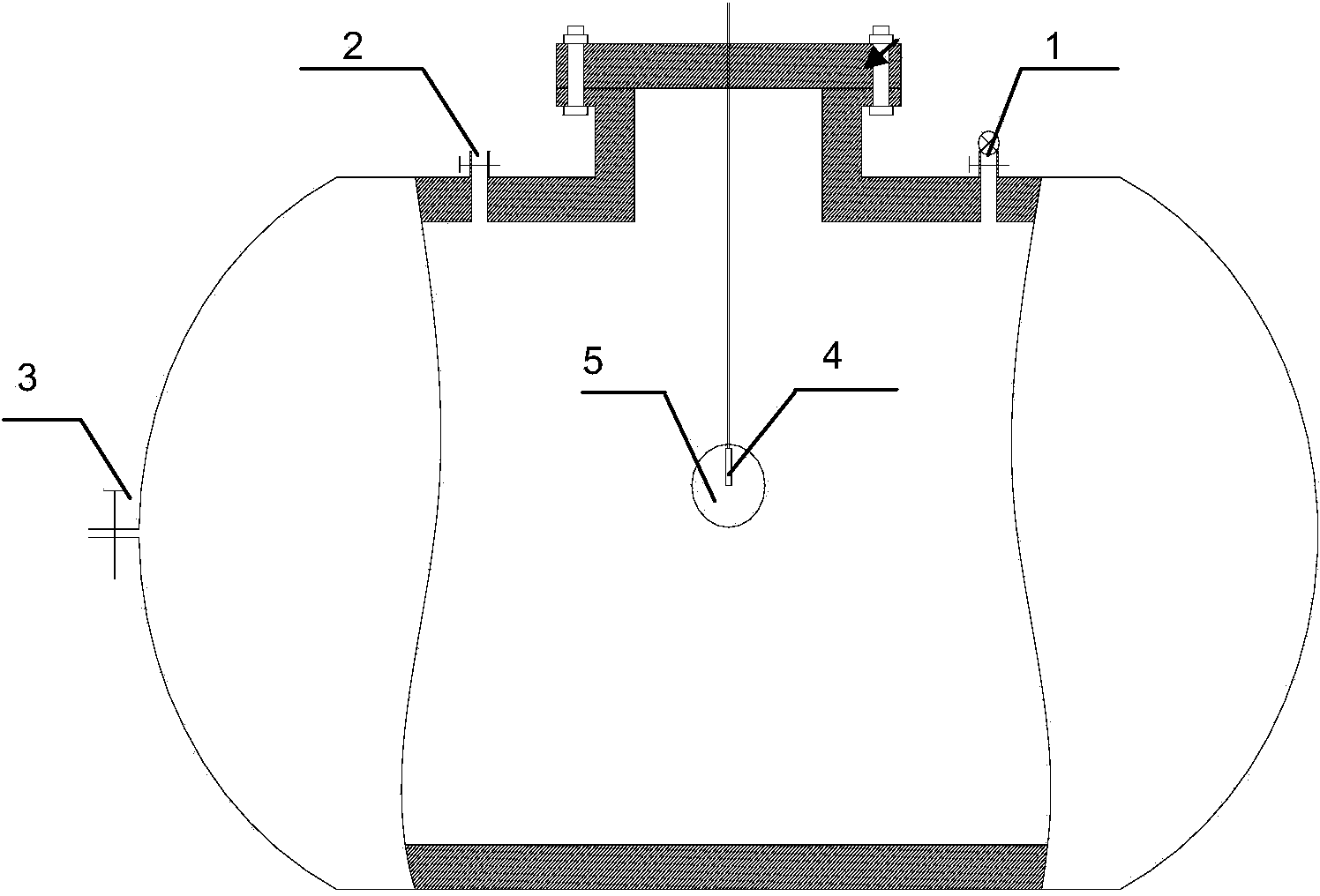

[0026] (6) Mix the powder with 42g of RDX, place it in an explosion vessel for d...

Embodiment 2

[0028] (1) Add 1 g of boric acid to 30 ml of distilled water, add 9 g of nano-diamonds into the boric acid solution, mix evenly by ultrasonic, then heat and dry at 100°C.

[0029] (2) Put the boric acid diamond into a heat treatment furnace and calcinate at 400°C to 450°C for half an hour to boride the surface of the diamond particles, then wash it several times with distilled water, remove excess boric acid, and dry at 100°C.

[0030] (3) Take 18g of aluminum nitrate and dissolve it in 100ml of distilled water, add borated nano-diamonds, and ultrasonically disperse;

[0031] (4) Add ammonia water dropwise to the aluminum nitrate solution, and after obtaining the precipitate, add 0.1mol / L concentration hydrochloric acid to the solution to adjust the pH value to 3-4, and place it for aging for 30 hours;

[0032] (5) Filter out the mixed sediment, heat and dry at 100-150°C, and pulverize to obtain powder;

[0033] (6) Mix the powder with 70g of RDX to prepare a precursor, and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com