Preparation method of bio-based modified amino polyol

A bio-based, polyol technology, applied in the field of bio-based, can solve the problems of large TDA residue, high VOC content, affecting life and health, etc., and achieve the effect of low VOC content, less residual toxic and harmful substances, and low hydroxyl value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

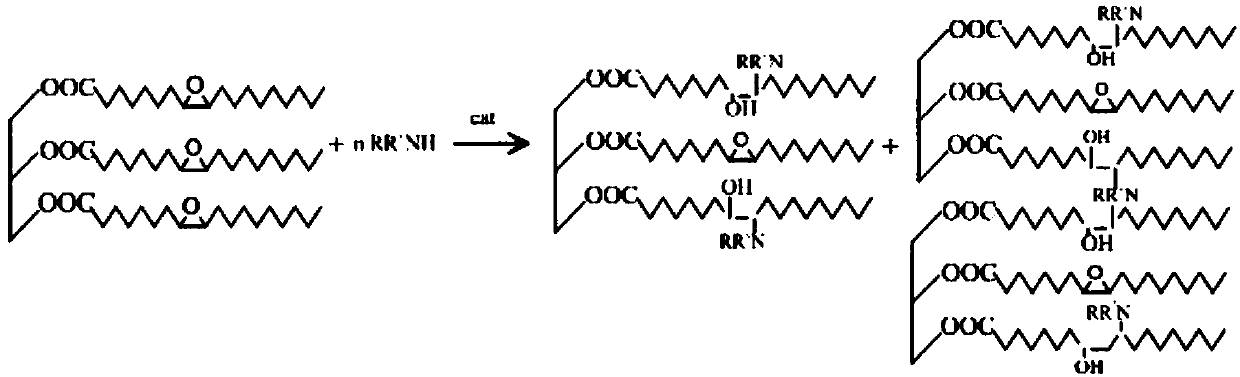

Method used

Image

Examples

Embodiment 1

[0025] Add 200g of monoethanolamine, 600g of epoxidized soybean oil, and 1.5g of potassium hydroxide into the stirring reaction device in sequence. Vacuum nitrogen replacement for 3 times, close the valve, turn on stirring, heat up to 120°C, react at a pressure of 0.1MPa for 12 hours, heat up to 125-130°C, vacuumize to a pressure of -0.096MPa, vacuumize, dehydrate and filter to obtain a bio-based modified amine base polyol I. Add 2.5g of 85% phosphoric acid to the bio-based modified amino polyol for neutralization reaction, then use 2g of refined magnesium silicate and 2g of aluminum silicate for adsorption, refinement, dehydration, decolorization, and vacuum dehydration and filtration to produce The refined bio-based modified amino polyol I was obtained.

Embodiment 2

[0027] Add 600g of epoxidized soybean oil and 1.8g of potassium hydroxide to the stirring reaction device in turn. Vacuum nitrogen replacement for 3 times, close the valve and stir to raise the temperature to 90°C, then slowly add 100g of dimethylamine and 20g of monomethylamine dropwise, and react for 12 hours under the condition of pressure less than or equal to 0.3MPa, when the reaction pressure is less than 0.1MPa, raise the temperature to 120-130°C, vacuumize to a pressure of -0.096MPa, vacuumize, dehydrate and filter to obtain bio-based modified amino-based polyol II. Add 2.2g of 85% phosphoric acid to the bio-based modified amino polyol for neutralization reaction, then use 1.8g of refined magnesium silicate and 1.8g of aluminum silicate for adsorption, refinement, dehydration, decolorization, and vacuum dehydration The refined bio-based modified amino polyol II was obtained by filtration.

Embodiment 3

[0029] Add 600g of epoxy linseed oil and 1.8g of potassium methylate into the stirring reaction device in sequence. Vacuum nitrogen replacement for 3 times, close the valve and stir to raise the temperature to 100°C, then slowly add 100g of ammonia water dropwise, and react for 18 hours under the condition of pressure less than or equal to 0.3MPa. Vacuum to a pressure of -0.096 MPa to obtain a bio-based modified amino polyol III by vacuum dehydration and filtration. Add 2.3g of 85% phosphoric acid to the bio-based modified amino polyol for neutralization reaction, then use 1.9g of refined magnesium silicate and 1.9g of aluminum silicate for adsorption, refinement, dehydration, decolorization, and vacuum dehydration The refined bio-based modified amino polyol III was obtained by filtration.

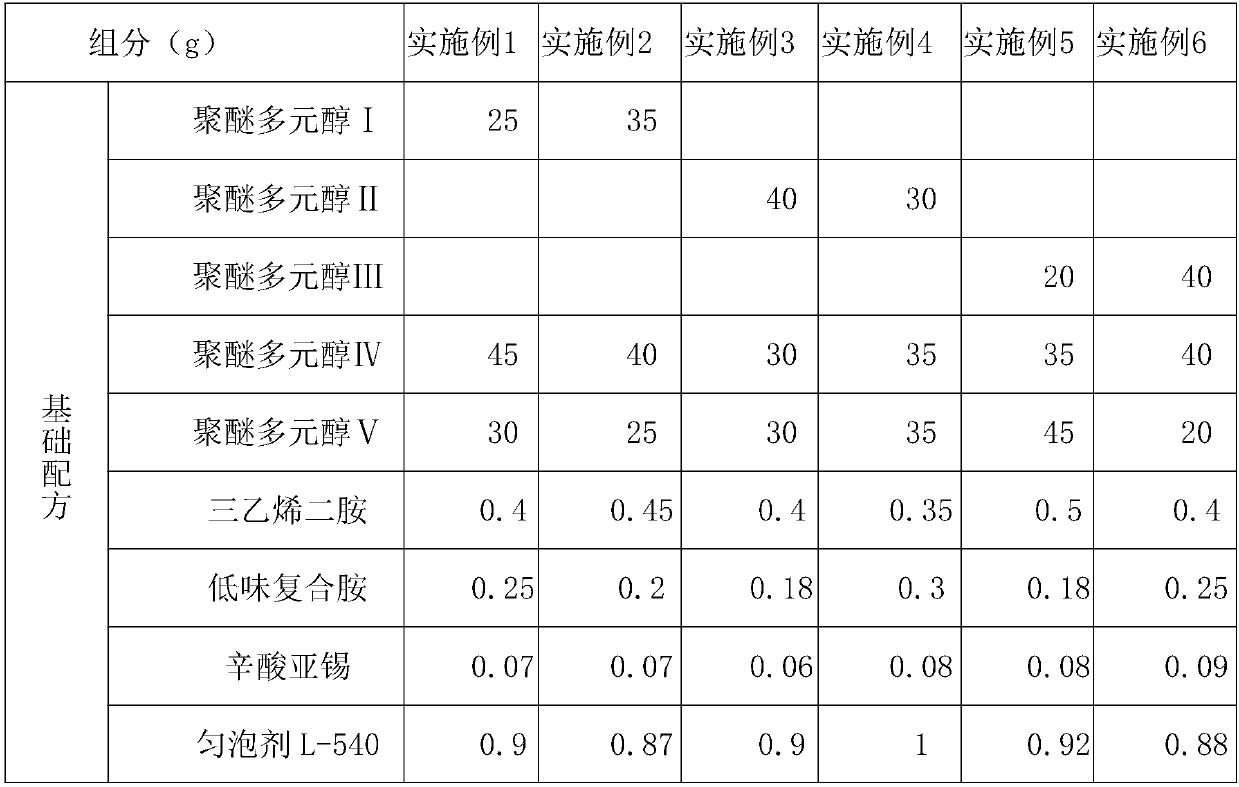

[0030] Each embodiment is prepared according to the following method: each raw material is put into the container by the portion given in Table 1 and stirred evenly (polyether polyol, cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com