Modified phenolic resin as well as preparation method and application thereof

A phenolic resin and modification technology, applied in the field of modified phenolic resin and its preparation, can solve the problems of reducing the thermal stability and flame retardant performance of the resin, decreasing the quality stability, complicated preparation process, etc. The effect of gel time and extension of dehydration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

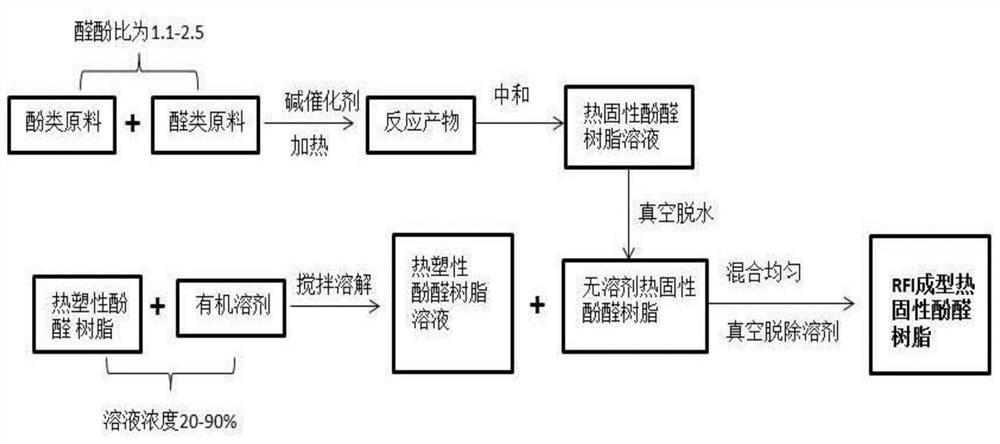

Method used

Image

Examples

Embodiment 1

[0061] The preparation of the RFI resin (RFI-10) of embodiment 1 thermoplastic phenolic resin consumption 10%

[0062] (1) Preheat the 30L reactor to 30°C, add 9.5 kg of melted phenol and 11.2 kg of 37.5% formaldehyde solution into the above reactor, stir evenly, add 95 grams of ammonia water, and heat up while stirring. When the temperature reaches 65°C, keep the reaction for 0.5 hours. At a speed of 2°C / min, the temperature of the reactor was raised to 80°C, and the reaction was further kept at 80±1°C for 2 hours. The temperature of the reactor was further raised to 95° C. at a rate of 2° C. / min, and the temperature was kept at 95±1° C. for 0.5 hours, and the addition and condensation reaction stage ended.

[0063] Cool the contents of the reactor to 50°C, and add hydrochloric acid to neutralize to pH 4.0.

[0064] Reheat the material. When the temperature of the material rises to 55°C, vacuum dehydration starts. When most of the water in the system is removed, the system ...

Embodiment 2

[0070] The preparation of the RFI resin (RFI-20) of embodiment 2 thermoplastic phenolic resin consumption 20%

[0071] (1) Preheat the 30L reactor to 30°C, add 9.5 kg of melted phenol and 8.8 kg of 37.5% formaldehyde solution into the above reactor, stir evenly, add 475 grams of barium hydroxide, and stir while stirring. The temperature was raised, and when the temperature reached 65° C., the reaction was kept for 0.5 hours. At a speed of 2°C / min, the temperature of the reactor was raised to 85°C, and the reaction was further kept at 80±1°C for 1 hour. The temperature of the reactor was further raised, and the temperature was raised to reflux at a rate of 2° C. / min, and the reaction was carried out for 1.0 hour, and the addition and condensation reaction stage ended.

[0072] Cool the contents of the reactor to 50°C, add phosphoric acid to neutralize to pH 7.5, and filter to remove the precipitate.

[0073] Reheat the material. When the temperature of the material rises to 5...

Embodiment 3

[0080]The preparation of the RFI resin (RFI-30) of embodiment 3 thermoplastic phenolic resin consumption 30%

[0081] (1) The reactor is preheated to 30°C, 7.6 kg of melted phenol, 545 g of m-cresol, 735.4 g of naphthol, 1.7 kg of 3-phenylphenol and 20 kg of 37.5% formaldehyde solution are added to the above reaction In the kettle, after stirring evenly, add 317.7 grams of sodium hydroxide, stir while raising the temperature, when the temperature reaches 65°C, keep the temperature for 1 hour. At a speed of 2°C / min, the temperature of the reactor was raised to 80°C, and the reaction was further kept at 80±1°C for 1 hour. The temperature of the reactor was further raised to 85±1° C. at a rate of 2° C. / min, and reacted for 2.0 hours. The addition and condensation reaction stage ended.

[0082] Cool the contents of the reactor to 50°C, and add hydrochloric acid to neutralize to pH 5.0.

[0083] Reheat the material. When the temperature of the material rises to 55°C, start vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| gel time | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com