Taro powder making device

A production device, taro powder technology, applied in the direction of heating devices, refrigerators, refrigeration and liquefaction, etc., can solve the problems of many processes, low production efficiency, high production cost, etc., and achieve the goal of increasing dehydration time, increasing the stroke, and saving processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

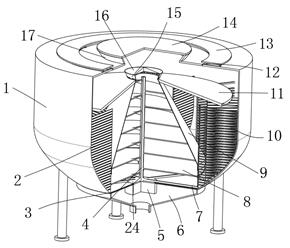

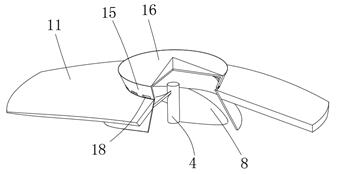

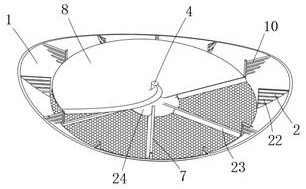

[0027] refer to Figure 1-5 , a kind of taro flour making device, comprising an outer cylinder body 1, the top outer wall of the outer cylinder body 1 is provided with a feeding hopper 17, and the top outer wall of the feeding hopper 17 is covered with a feeding cover 14, and the side inner wall of the outer cylinder body 1 is passed through a connecting rod The material distribution plate 11 is fixedly connected, and the side inner wall of the material distribution plate 11 is fixedly connected with the conical shell 9, the top outer wall of the material distribution plate 11 is fixedly connected with the extruding shell 15, and the side outer wall bottom of the extruding shell 15 has a Ring-shaped evenly distributed extrusion openings 18, the bottom inner wall of the outer cylinder 1 is fixedly connected with a screen 3, and the side inner wall of the screen 3 is connected with a shaft 4 extending to the inside of the conical shell 9 through a bearing, and the side outer wall...

Embodiment 2

[0036] refer to Figure 6 , a kind of taro powder production device, this embodiment is compared with embodiment 1, in order to improve the drying effect of pasty taro on the material distribution plate 11, the top outer wall of the material distribution plate 11 is fixedly connected with the dislocation distribution of the extrusion port 18 The guide bar 25, and the guide bar 25 is a helical structure.

[0037] When the present invention is in use: compared with Embodiment 1, when the paste taro is extruded in strips from the extrusion port 18, the strip paste taro will fall in a spiral shape on the distribution plate 11 along the guide bar 25 , And then improve the stroke of the paste taro on the material distribution plate 11, and then improve the drying effect of the paste taro.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com