Method for preparing foam glass particles from silica powder

A foam glass and silicon micropowder technology, applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve the problem of low recycling rate, and achieve the effects of low production cost, uniform foaming, and saving of grinding process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

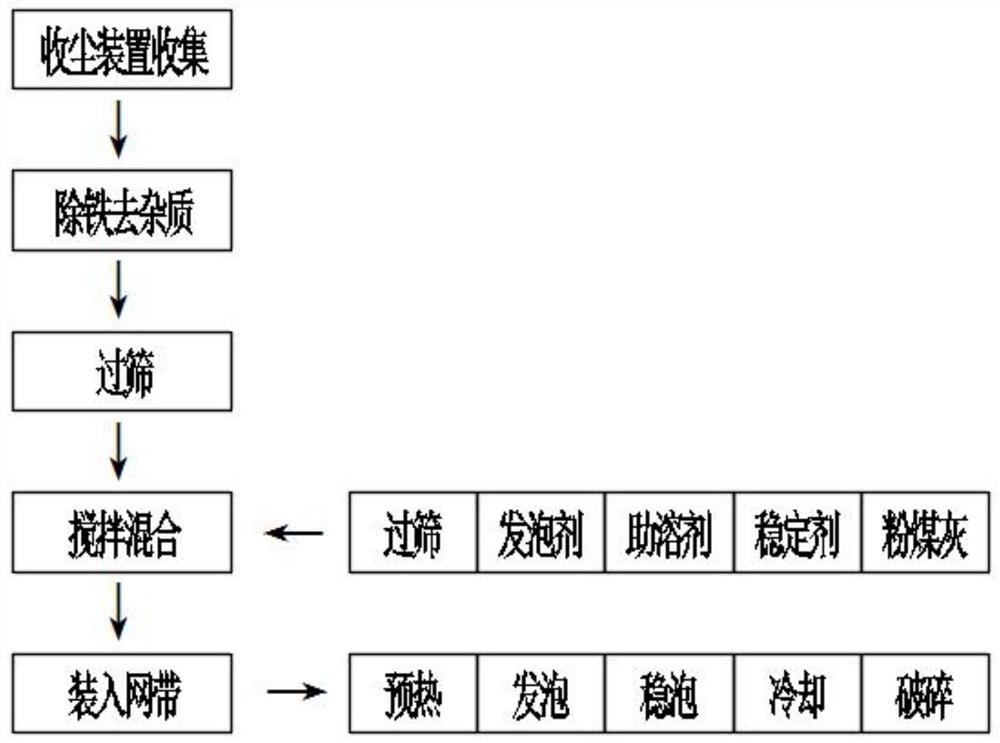

[0029] Follow these steps:

[0030] Step 1: Carry out iron removal and other treatments on the silicon micropowder collected by the dust collection device to remove impurities, and the fly ash must be sieved with 200 mesh;

[0031] Step 2: The raw material formula is calculated by weight percentage, with 80% silicon micropowder, 2% foaming agent, 1% stabilizer, 1% cosolvent, and the rest is fly ash, and the above raw materials are fully mixed and stirred evenly to prepare Obtain mixture, foaming agent is calcium carbonate, silicon carbide and carbonates, stabilizer is boric acid, sodium carbonate and sodium sulfate, cosolvent is sodium carbonate, sodium fluorosilicate and borax;

[0032] Step 3: Put the mixture on the heat-resistant steel dense mesh belt that has been painted with release agent, put it into the furnace and preheat it: put the mixture on the heat-resistant steel dense mesh belt, and the mesh belt runs continuously into the Furnace, the mixture is preheated at ...

Embodiment 2

[0035] Follow these steps:

[0036] Step 1: Carry out iron removal and other treatments on the silicon micropowder collected by the dust collection device to remove impurities, and the fly ash must be sieved with 200 mesh;

[0037] Step 2: The raw material formula is calculated by weight percentage, with 90% silicon micropowder, 4% foaming agent, 3% stabilizer, 2% cosolvent, and the rest is fly ash, and the above raw materials are fully mixed and stirred evenly to prepare Obtain mixture, foaming agent is calcium carbonate, silicon carbide and carbonates, stabilizer is boric acid, sodium carbonate and sodium sulfate, cosolvent is sodium carbonate, sodium fluorosilicate and borax;

[0038] Step 3: Put the mixture on the heat-resistant steel dense mesh belt that has been painted with release agent, put it into the furnace and preheat it: put the mixture on the heat-resistant steel dense mesh belt, and the mesh belt runs continuously into the Furnace, the mixture is preheated at ...

Embodiment 3

[0041] Follow these steps:

[0042] Step 1: Carry out iron removal and other treatments on the silicon micropowder collected by the dust collection device to remove impurities, and the fly ash must be sieved with 200 mesh;

[0043] Step 2: The raw material formula is calculated by weight percentage, with 85% silicon micropowder, 3% foaming agent, 2% stabilizer, 1.5% cosolvent, and the rest is fly ash, and the above raw materials are fully mixed and stirred evenly to prepare Obtain mixture, foaming agent is calcium carbonate, silicon carbide and carbonates, stabilizer is boric acid, sodium carbonate and sodium sulfate, cosolvent is sodium carbonate, sodium fluorosilicate and borax;

[0044] Step 3: Put the mixture on the heat-resistant steel dense mesh belt that has been painted with release agent, put it into the furnace and preheat it: put the mixture on the heat-resistant steel dense mesh belt, and the mesh belt runs continuously into the Furnace, the mixture is preheated a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com