Pectin dedicated volute sludge dehydrator and screw shaft thereof

A technology of sludge dewatering machine and screw shaft, which is applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/thickened sludge treatment, etc., which can solve the problem of reducing equipment processing capacity and increasing equipment one-time investment and other problems to achieve good dehydration effect, improved processing efficiency and long dehydration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

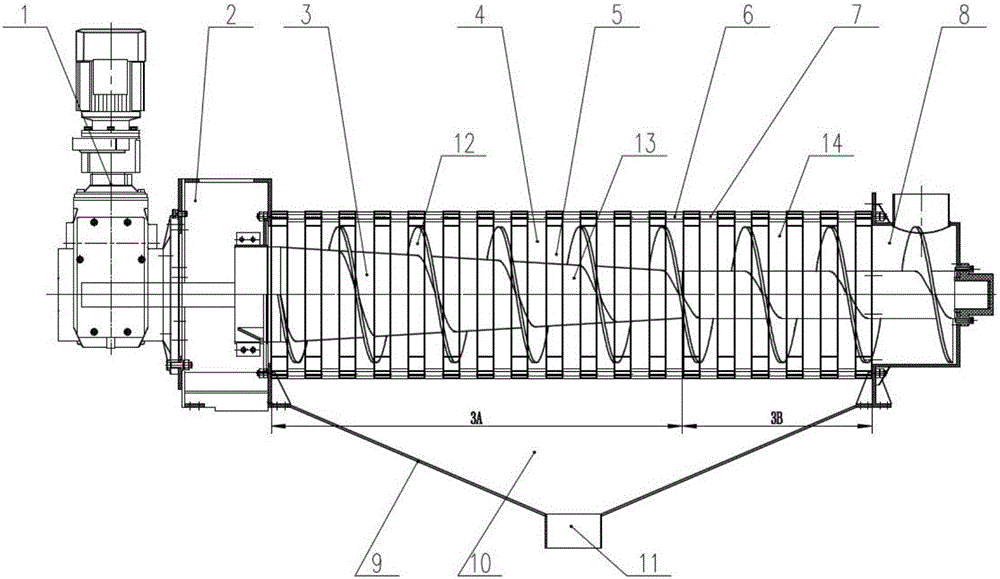

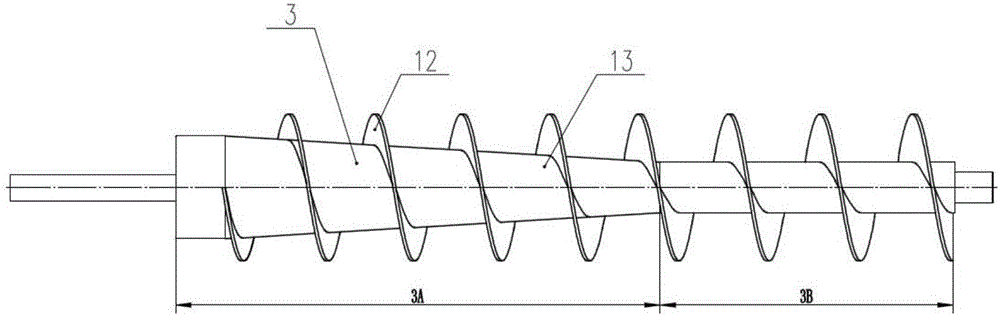

[0022] Such as figure 2 As shown, the screw shaft 13 of a pectin special-purpose screw-packed sludge dehydrator of the present invention adopts a screw shaft with variable diameter and pitch. ) gradually decreases along the direction of the mud box; the diameter of the screw shaft gradually increases along the direction of the mud box from the position of 1 / 3 of the shaft length. The length of the rear 2 / 3 section (ie dehydration section 3A) of the screw shaft increases by 10-15%.

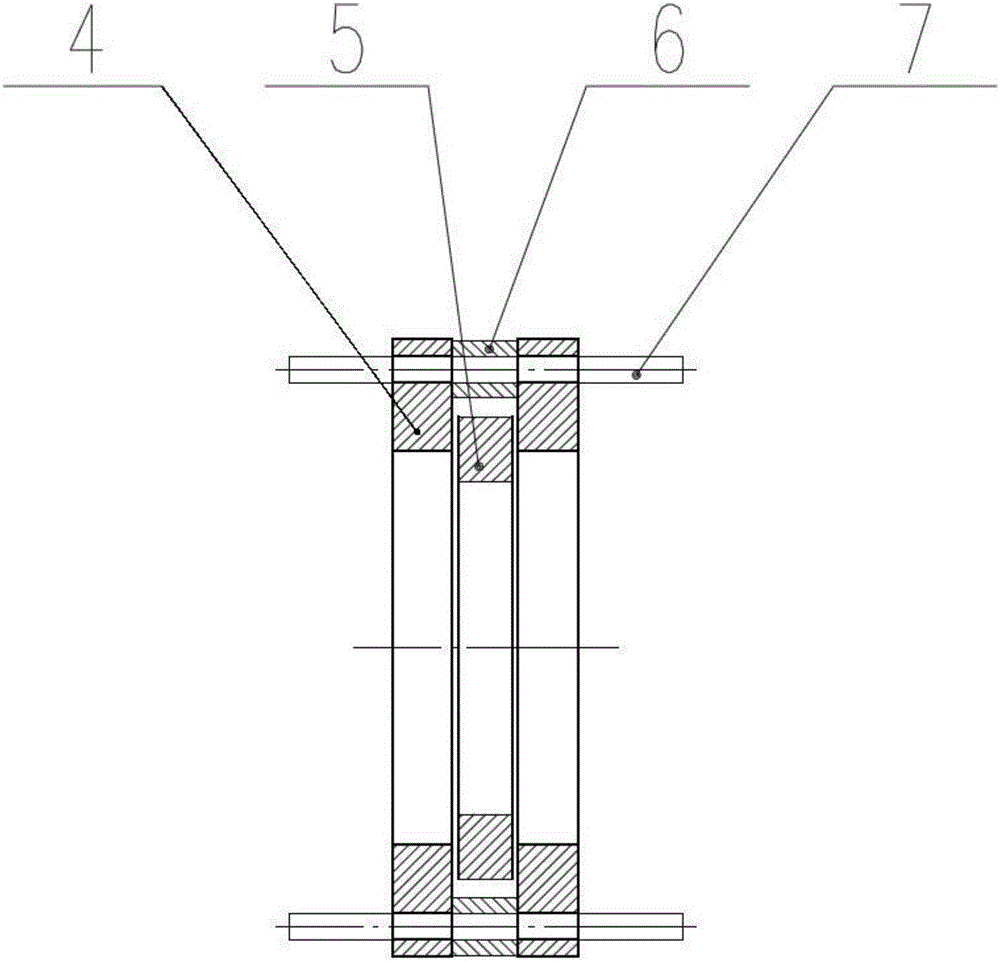

[0023] Such as figure 1 As shown, the present invention is a pectin-specific stacked screw sludge dehydrator, which includes a filter body 14 composed of a fixed ring 4, a movable ring 5 and the above-mentioned screw shaft 13, and also includes a casing 9, a filtrate collection tank 10, Filtrate outlet 11, inlet mud box 8 and mud box 2; several fixed rings 4 (annular fixed laminations) are arranged in sequence in the inside of the casing 9, and the configuration between adjacent fixed rings 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com