Tank field temperature maintaining and rising system

A technology for tank farms and storage tanks, used in heating systems and temperature maintenance in tank farms, can solve the problems of high energy consumption and cost, slow heating speed, pipeline leakage, etc., so as to reduce production costs and energy consumption, and speed up dehydration time. , the effect of saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

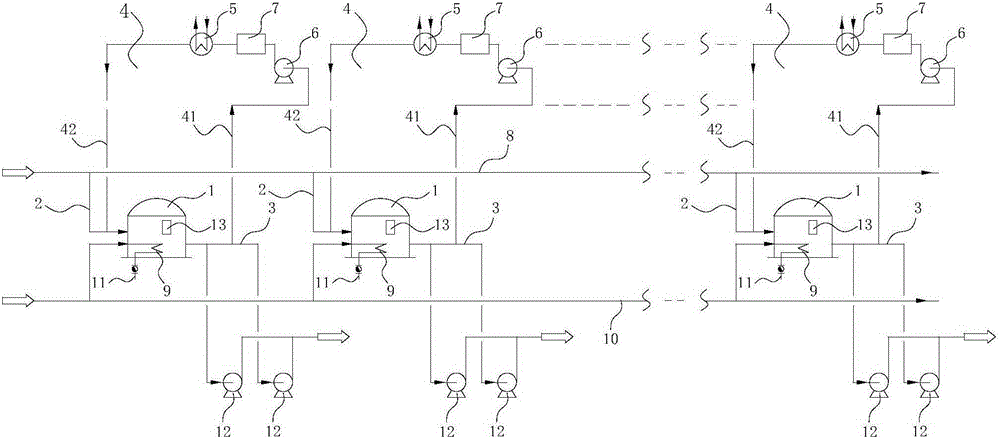

[0023] This embodiment provides a tank area temperature maintenance and temperature raising system, which is used for temperature maintenance and heating of the materials in the storage tank 1 in the tank area, such as figure 1 As shown, the system includes at least one storage tank 1, and the two sides of the storage tank 1 are respectively connected with a material inlet pipeline 2 and a material outlet pipeline 3, wherein the material inlet pipeline 2 is connected with a material conveying main pipeline 8, that is, the material is conveyed from the material The main pipeline 8 is transported to the storage tank 1 through the material inlet pipeline 2, the temperature maintenance pipeline 4 is connected to the material outlet pipeline 3, and the heat exchanger 5 is connected to the temperature maintenance pipeline 4. Specifically, the temperature maintenance pipeline 4 includes a first dimension Temperature pipeline 41 and the second temperature maintenance pipeline 42, where...

Embodiment 2

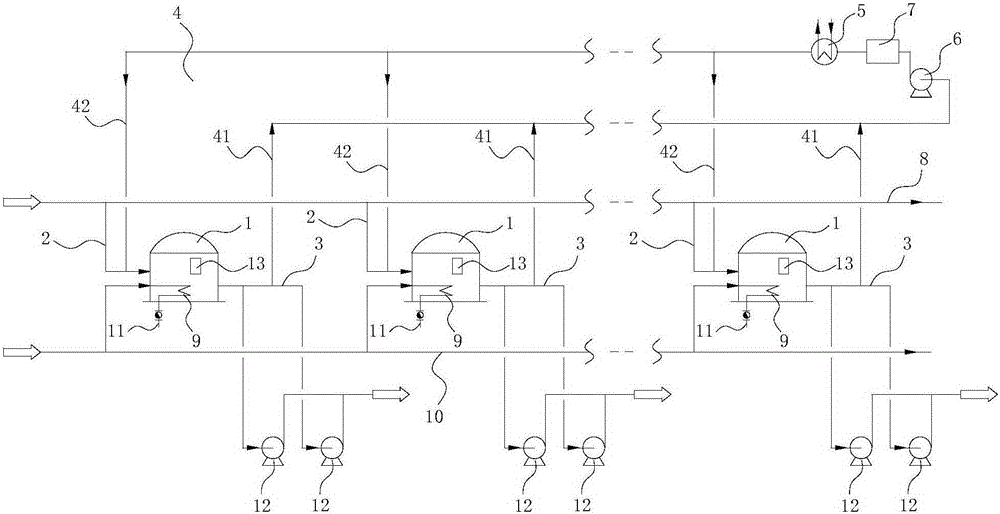

[0033] In this example, if figure 2 As shown, the difference from Embodiment 1 is that only one circulation pump 6, demulsifier dosing device 7, and heat exchanger 5 of this embodiment are provided. When the number of storage tanks 1 is more than one, each The first temperature-maintaining pipelines 41 connected to the material outlet pipeline 3 are all connected to each other, and one end of each first temperature-maintaining pipeline 41 that is not connected to the material outlet pipeline 3 is finally converged to the circulation pump 6 through the pipeline; The second temperature maintenance pipelines 42 connected to the inlet pipeline 2 are also connected to each other, and the materials after heat exchange from the heat exchanger 5 are transported to each second temperature maintenance pipeline 42 through the pipelines, and flow into the second temperature maintenance pipelines 42 from the second temperature maintenance pipelines 42. Each connected material inlet pipe 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com