Vehicle-mounted urea solution producing system and vehicle-mounted urea solution producing system restructuring method

A production system and technology of urea for vehicles, applied in chemical instruments and methods, dissolving, dissolving and other directions, can solve the problems of unevenness, uneven solution concentration, slow dissolving speed of granular crystalline urea, etc., to reduce energy consumption and production costs , the effect of improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to describe the technical features and functions of the present invention in detail and realize them according to the content of this specification, the implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0042] Unless otherwise specified, the terms "first" and "second" herein do not limit the sequence, sequence, nature, etc. of the terms matched therewith, and do not represent the importance of the terms matched therewith.

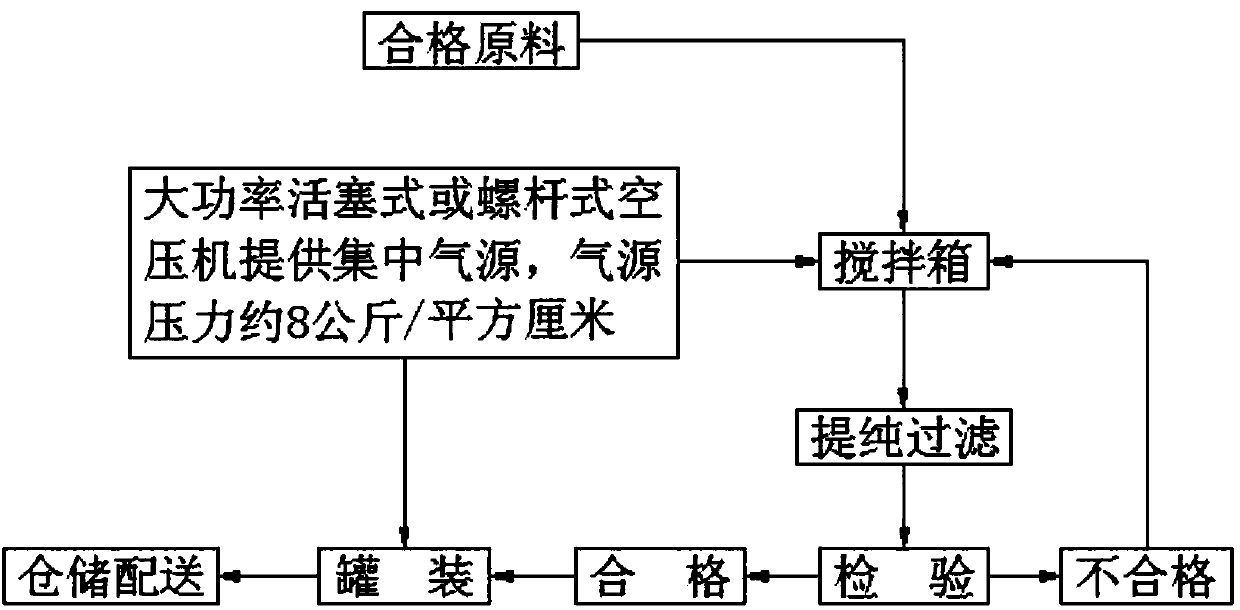

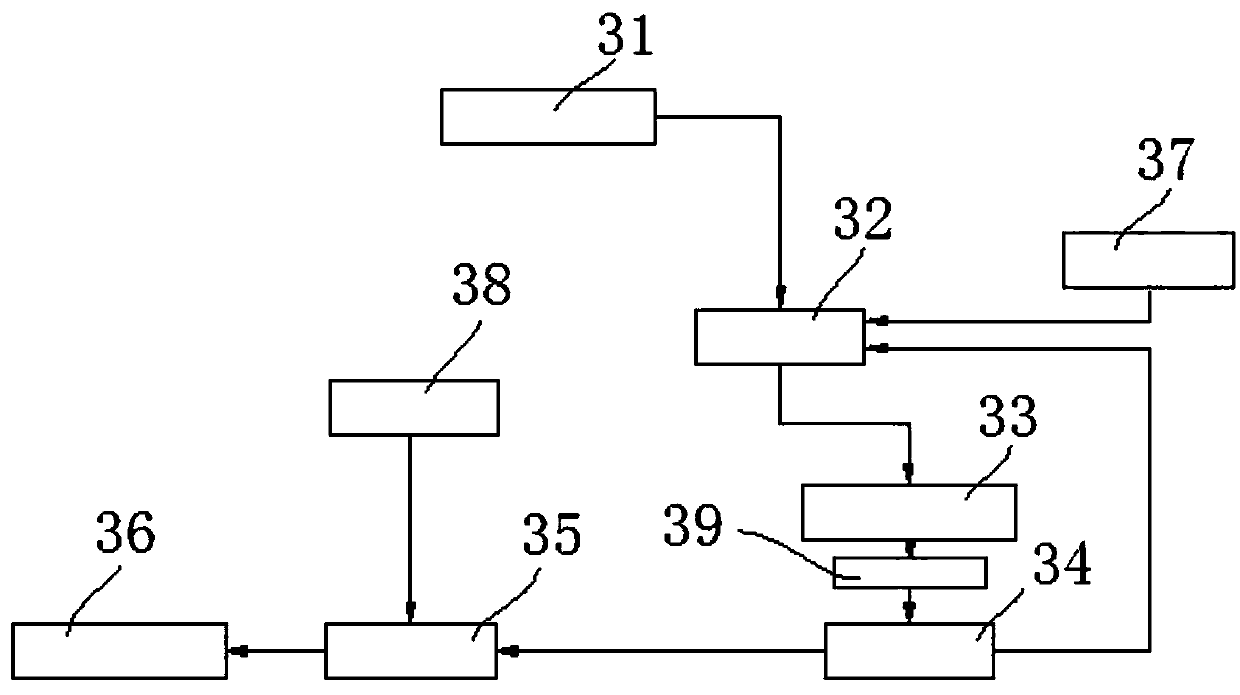

[0043] image 3 It schematically shows an embodiment of a vehicle urea solution production system among numerous vehicle urea solution production systems of the present invention. The vehicle urea solution production system includes raw material input equipment 31 , a stirring tank 32 , purification and filtration equipment 33 , inspection equipment 34 , and filling equipment 35 .

[0044] The raw material input device 31 is used to deliver the qualified raw material to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com