Method for producing silicon carbide with industrial waste residues

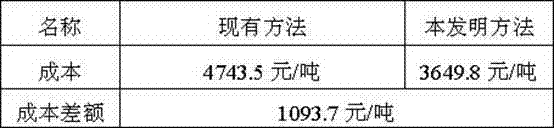

A technology of industrial waste residue and silicon carbide, which is applied to the removal of silicon carbide, carbide, and solid waste, can solve problems such as low production efficiency, high power consumption, and limited experimental research, and achieve reduced production costs and energy consumption. Improve production efficiency and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Break industrial waste residues (mainly various waste residues and waste coke powder produced by smelting ferrosilicon, roasted graphite electrode blocks and smelting silicon carbide, etc.) The silicon cleaning and blowing machine removes the dust and free carbon on the surface of the raw material particles, and then uses a magnetic separator to remove the iron mixed in the raw material particles, and then cleans, precipitates, and dries the raw material particles to obtain smelting raw materials; according to the silicon carbide smelting furnace The position of the charge in the smelting furnace, that is, the position of the charge in the smelting furnace is the upper part, the middle part or the lower part, and the ingredients are prepared according to different carbon-silicon ratios: according to the carbon-silicon ratio (mass ratio) 0.63, take The smelting raw materials and quartz sand are put into the forced mixer and stirred evenly to obtain the lower part of the c...

Embodiment 2

[0059] Break industrial waste residues (mainly various waste residues and waste coke powder produced by smelting ferrosilicon, roasted graphite electrode blocks and smelting silicon carbide, etc.) The silicon cleaning and blowing machine removes the dust and free carbon on the surface of the raw material particles, and then uses a magnetic separator to remove the iron mixed in the raw material particles, and then cleans, precipitates, and dries the raw material particles to obtain smelting raw materials; according to the silicon carbide smelting furnace The position of the charge in the smelting furnace, that is, the position of the charge in the smelting furnace is the upper part, the middle part or the lower part, and the ingredients are prepared according to different carbon-silicon ratios: according to the carbon-silicon ratio (mass ratio) 0.63, take The smelting raw materials and quartz sand are put into the forced mixer and stirred evenly to obtain the lower part of the c...

Embodiment 3

[0061] Break industrial waste residues (mainly various waste residues and waste coke powder produced by smelting ferrosilicon, roasted graphite electrode blocks and smelting silicon carbide, etc.) The silicon cleaning and blowing machine removes the dust and free carbon on the surface of the raw material particles, and then uses a magnetic separator to remove the iron mixed in the raw material particles, and then cleans, precipitates, and dries the raw material particles to obtain smelting raw materials; according to the silicon carbide smelting furnace The position of the charge in the smelting furnace, that is, the position of the charge in the smelting furnace is the upper part, the middle part or the lower part, and the ingredients are prepared according to different carbon-silicon ratios: according to the carbon-silicon ratio (mass ratio) 0.63, take The raw materials for smelting and quartz sand are put into the forced mixer and stirred evenly to obtain the lower charge; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com