Disc dehydration unit

A disc dehydration and locking device technology, applied in the field of dehydration devices, can solve the problems of high power required for drum dehydrator rotation, dehydration time of less than 30 seconds, and poor dehydration effect of granulated slag. Low moisture content of product slag, simple structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the purpose, structure and function of the present invention, a disk dehydration device of the present invention will be further described in detail below in conjunction with the accompanying drawings.

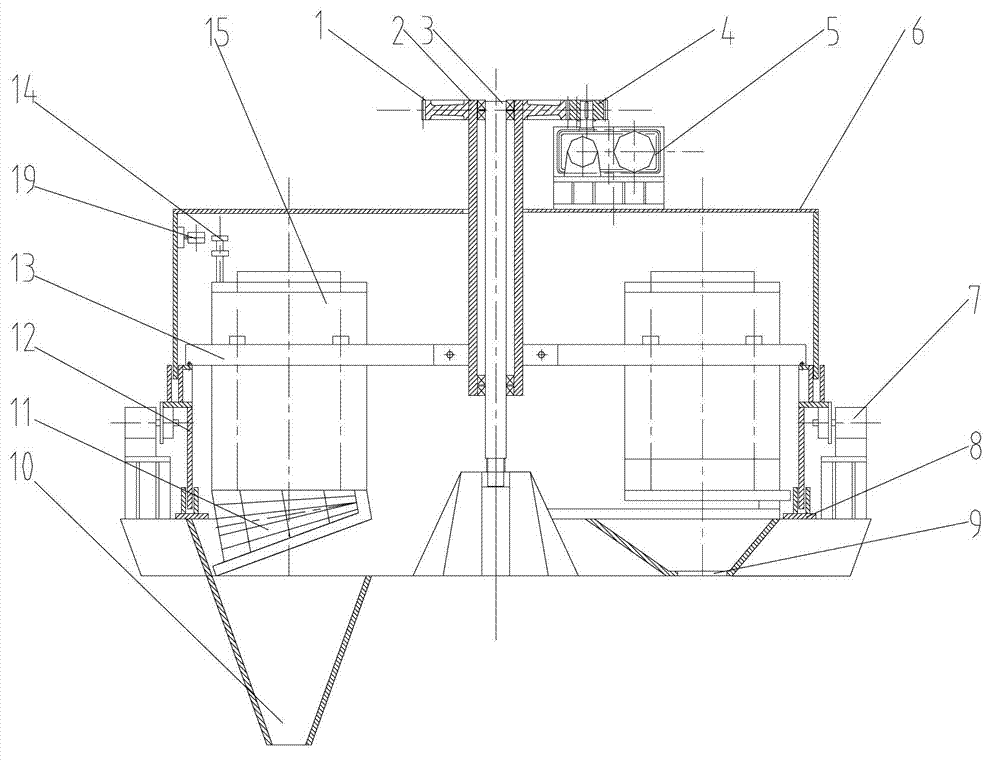

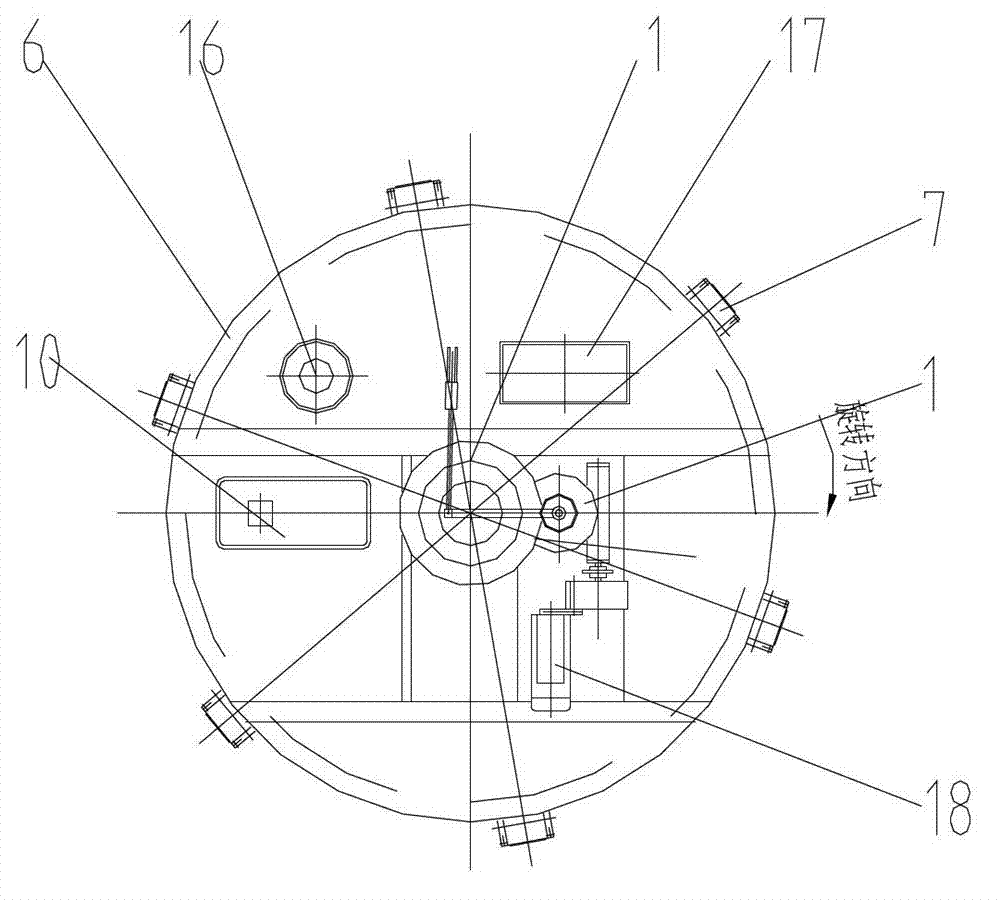

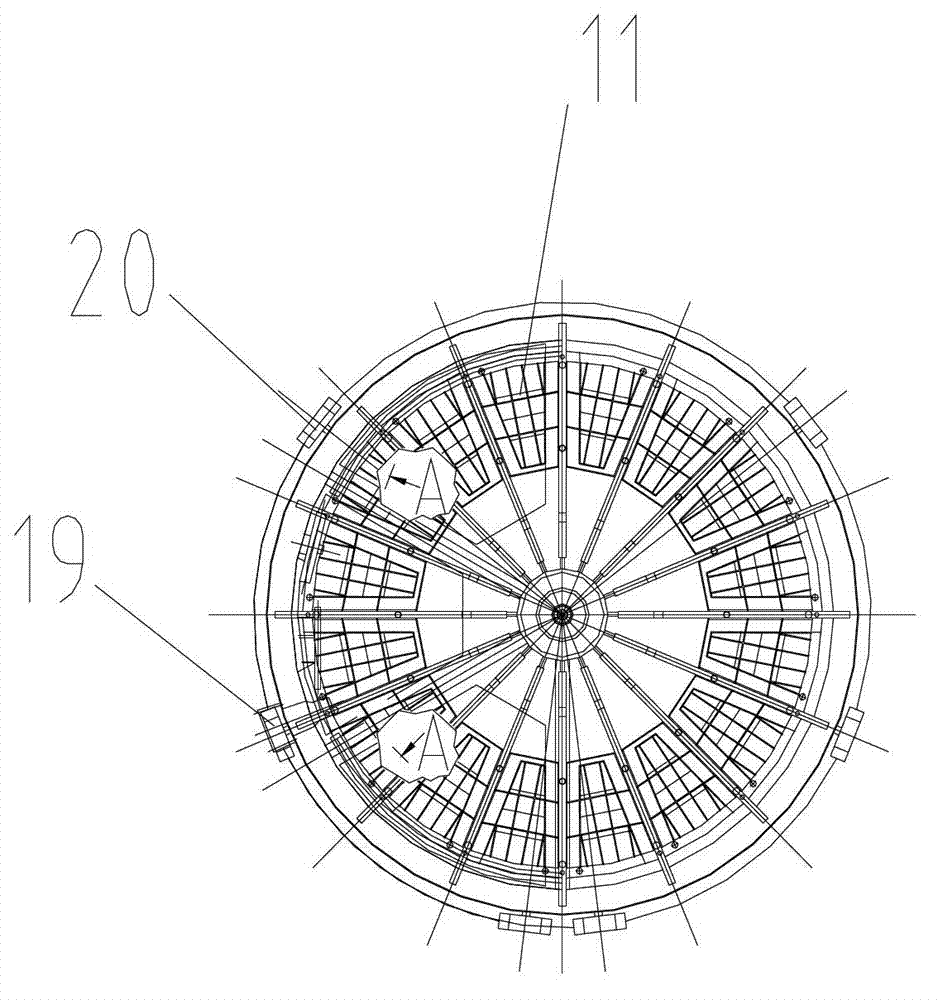

[0022] like figure 1 As shown, the disk dehydration device of the present invention includes a central pillar 3 and a rotating cylinder 12 rotating around the central pillar 3, wherein the upper part of the rotating cylinder 12 is provided with an upper cover 6, and the lower part is provided with a lower shell 8. The top of the upper cover 6 is provided with a material inlet 16 and a transmission part for driving the rotating cylinder 12 to rotate, and the bottom of the lower shell 8 is provided with a material outlet 10 .

[0023] Specifically, the upper cover 6, the lower shell 8 and the central pillar 3 in the present invention are all arranged on a fixed foundation (not shown in the figure), while the rotating cylinder 12 is supported ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com