Waste textile crushing, sorting and recycling equipment

A technology for waste textiles and recycling equipment, which is applied to the decomposition and restoration of textiles, recycling technology, solid separation, etc., to achieve the effects of improving crushing quality, improving efficiency, and reducing the probability of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

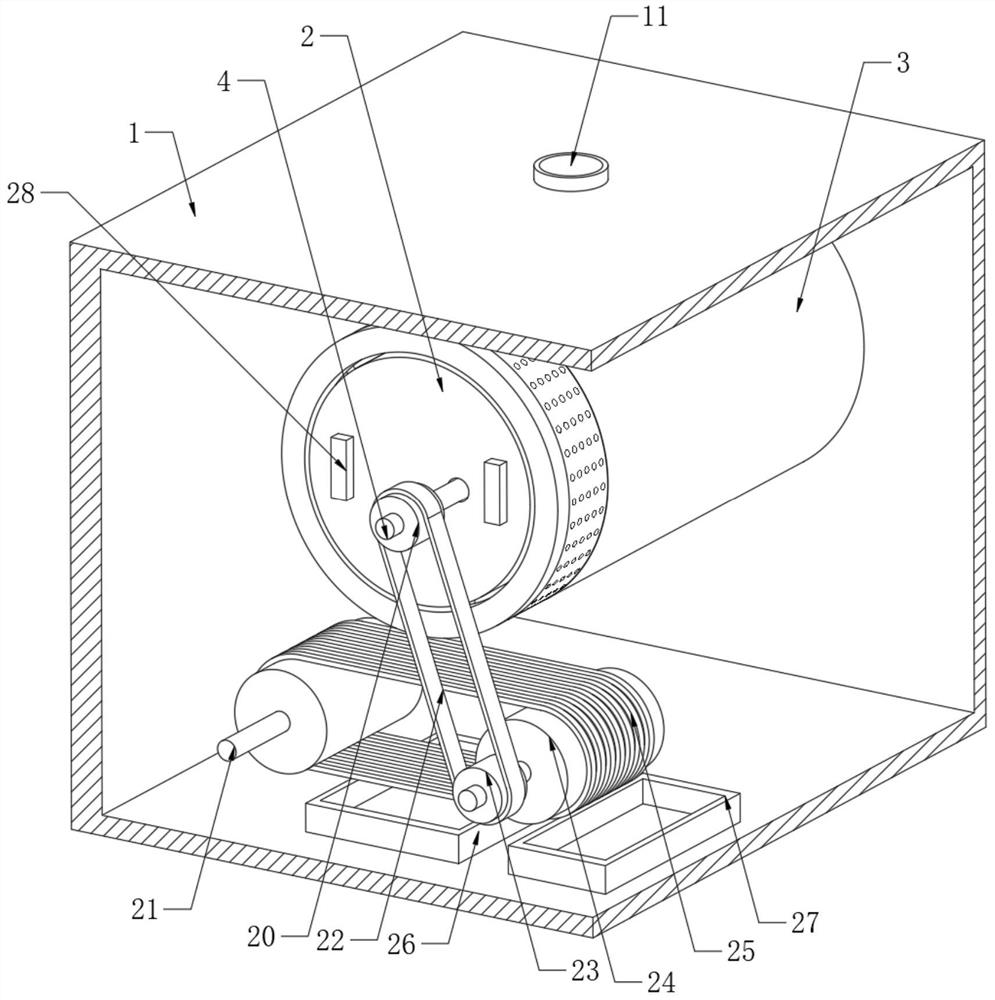

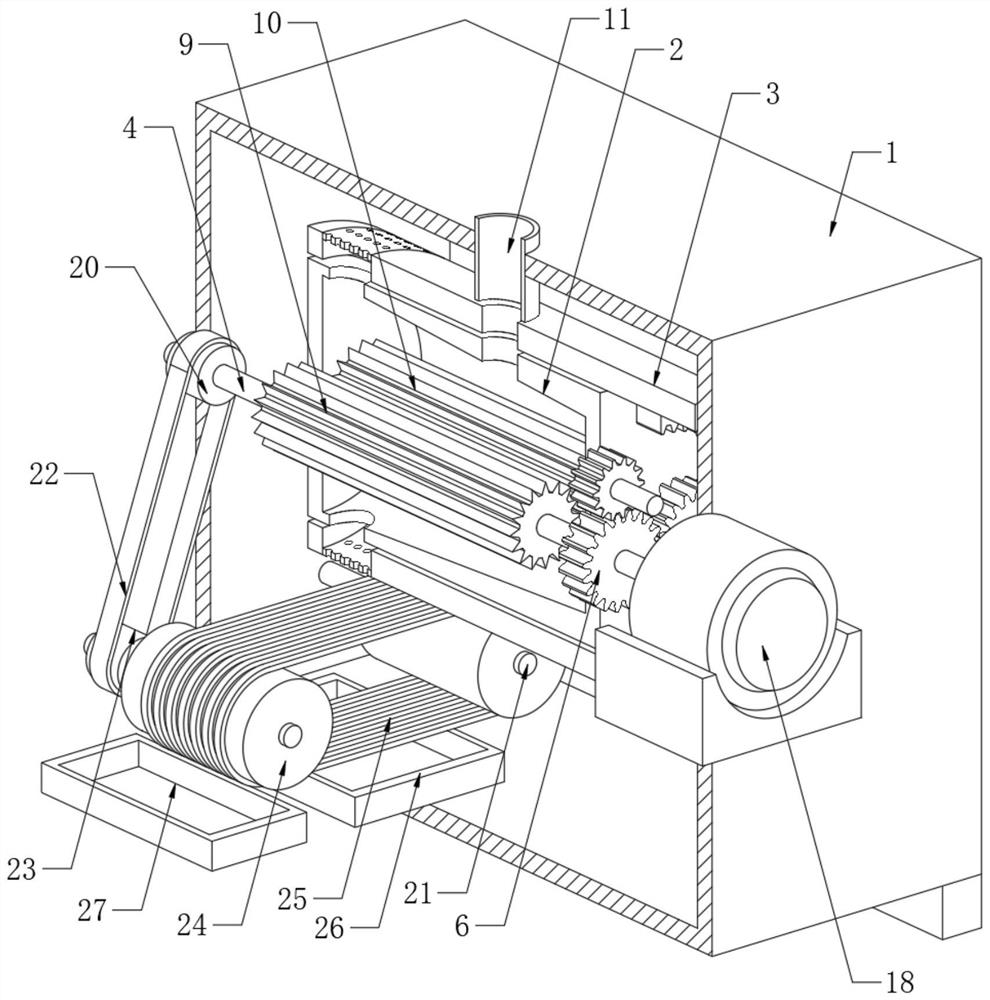

[0025] refer to figure 1 , figure 2 , image 3 , Figure 4 , Image 6 and Figure 7 As shown, a waste textile crushing, sorting and recycling equipment includes a box body 1, and a cylindrical fixed roller 2 is horizontally and fixedly connected to the inner wall of the box body 1 through a plurality of connecting plates 28. The fixed roller 2 is coaxially rotated and sleeved with Rotate the ring 3, and the inner wall of the rotating ring 3 is slidably connected with the peripheral wall of the fixed roller 2, the end of the rotating ring 3 away from the connecting plate 28 is rotatably connected with the inner wall of the box 1, and the side of the fixed roller 2 away from the connecting plate 28 is rotated symmetrically and horizontally. There are a first rotating shaft 4 and a second rotating shaft 5, the first rotating shaft 4 and the second rotating shaft 5 are respectively fitted with a first gear 6 and a second gear 7, and the first gear 6 and the second gear 7 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com