Ordered waste textile smashing equipment

A technology of waste textiles and crushing equipment, which is applied in the direction of grain processing, etc., which can solve the problems of difficult collection of textiles, troublesome manual collection, mechanism jamming, etc., and achieve the effects of reducing the probability of blockage, slowing down the falling speed, and improving the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

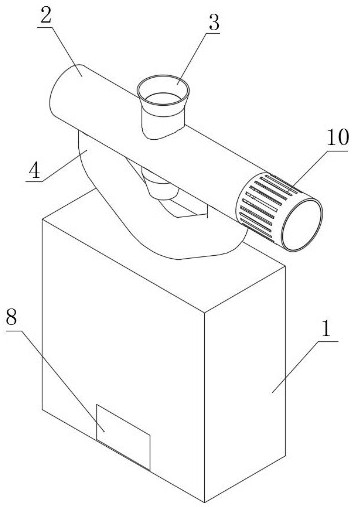

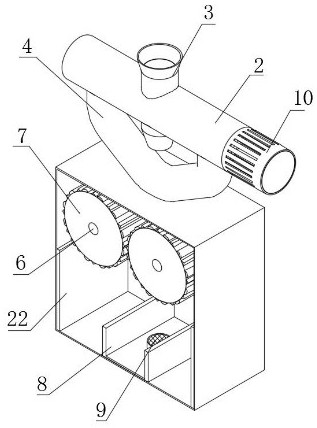

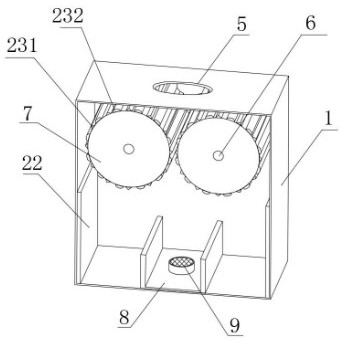

[0024] refer to Figure 1-3 , an orderly waste textile crushing equipment, including a housing 1 and an electric control assembly, the top of the housing 1 is provided with a feed port 5, the feed port 5 is sealed and connected with a feed pipe 4, and the feed pipe 4 is far away from the feed port One end of 5 is symmetrically provided with two openings, and the two openings are jointly sealed and connected with a material distribution cylinder 2, and the top center of the material distribution cylinder 2 is connected with a feed hopper 3, and a uniform material distribution structure is arranged inside the material distribution cylinder 2. 1 is provided with crushing collection structure.

[0025] refer to Figure 4-5 , the crushing and collecting structure includes two rotating shafts 6, the electric control component is connected with the two rotating shafts 6 through the gear structure provided, so that the two rotating shafts 6 rotate at the same speed in opposite direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com