Full-automatic steel pipe knurling system

A fully automatic, knurled technology, applied in metal processing and other directions, can solve problems such as unstable product quality, and achieve the effect of reasonable design, production safety, quality and consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

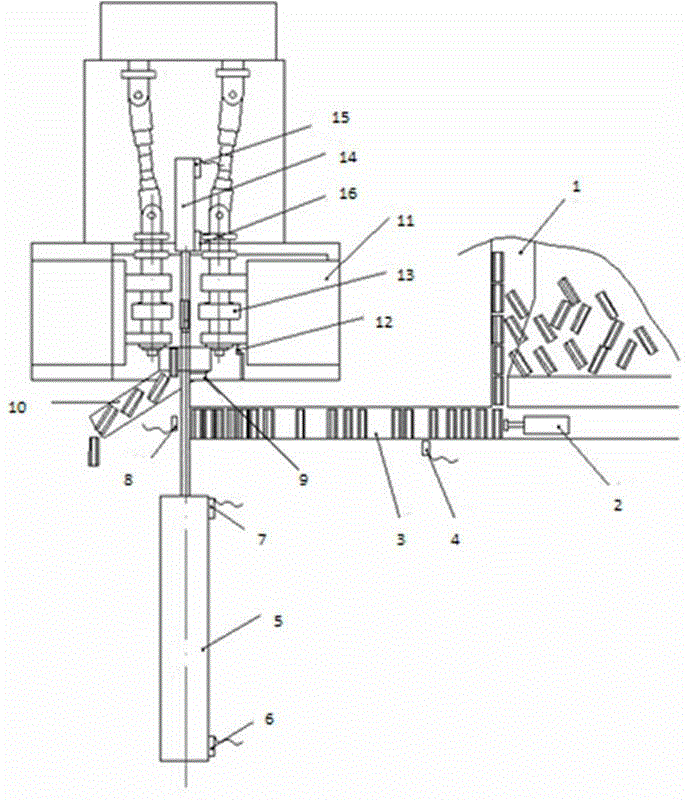

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0016] Such as figure 1 As shown, a steel pipe automatic knurling system includes a linear vibrating feeding machine 1, a first feeding cylinder 2, a material channel 3 (inclined installation, the product automatically rolls down), a first magnetic cylinder 5, a material shifting block 9, Material receiving box 10, thread rolling machine 11, thread rolling wheel travel switch 12, thread rolling wheel 13, second magnetic cylinder 14 (returning material).

[0017] Two sets of thread rolling wheels 13 are installed in the middle of the top of the thread rolling machine 11 , and the thread rolling wheels 13 are all provided with corresponding thread rolling wheel travel switches 12 . Its effect is when the thread rolling wheel 13 retreats and touches the thread rolling wheel travel switch 12 after the processing of the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com