A vertical fully automatic continuous boiling granulator and sugar alcohol granulation method

A boiling granulator, fully automatic technology, applied in the direction of sugar products, sucrose production, sugar production, etc., can solve the problems of continuous flakes, long single-batch granulation cycle, high granulation cost, etc., and achieve small installation space , controllable continuous production, and the effect of reducing equipment energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

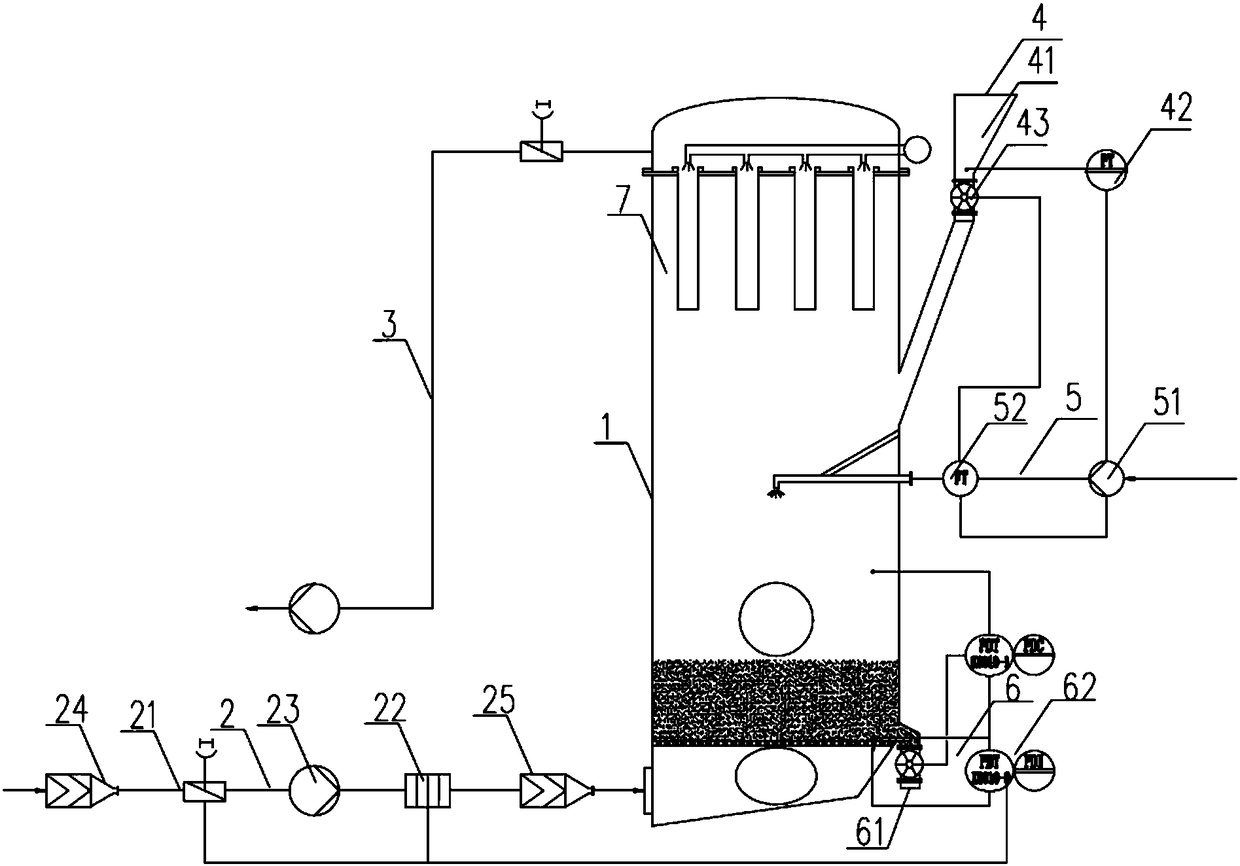

[0034] A vertical fully automatic continuous boiling granulator, such as figure 1 Shown, the present invention comprises control unit (not shown in the figure), granulation chamber 1, air inlet unit 2, air outlet unit 3, feed unit 4, spray liquid unit 5, dust catch unit 7 and discharge unit 6. The discharge unit 6 includes a discharge rotary valve 61 for controlling the output of the pellets from the granulation chamber 1. The discharge unit 6 also includes a discharge differential pressure sensor 62. The control unit receives the pressure signal output by the discharge differential pressure sensor 62. , and control and adjust the size of the discharge rotary valve 61 according to the pressure signal.

[0035] The air intake unit 2 includes an air intake door 21 for supplying air to the granulation chamber 1, a centrifugal fan 23, a medium-efficiency filter 24, a high-efficiency filter 25, and a heater 22 for heating the wind. The heater 22 And the interlocking of the air inl...

Embodiment 2

[0038] Utilize the vertical full-automatic continuous boiling granulator in embodiment 1 to carry out granulation, take xylitol granulation as example, comprise the following steps:

[0039] (1) After setting all parameters, open the air inlet unit, wherein the air inlet door opening is 20%, the heater temperature is 60°C, and hot air is introduced into the granulation chamber;

[0040] (2) The powdery xylitol is delivered to the granulation chamber 1 via the feed unit 4, and the liquid spray unit 5 is opened, so that the binder is delivered to the granulation chamber 1 with the powdery xylose via the liquid spray unit 5. Alcohol is subjected to boiling granulation, wherein the flow rate of the flow meter 52 of the spray unit 5 is 10 L / h, and the rotation frequency of the feed rotary valve is 30-35 Hz;

[0041] When the boiling height of the material rises to 65cm, control the opening of the pressure difference valve inlet door 21 to 75-85%, the temperature of the heater 22 ri...

Embodiment 3

[0047] Utilize the vertical automatic continuous boiling granulator in embodiment 1 to carry out granulation, take maltitol granulation as example, comprise the following steps:

[0048] (1) After setting all parameters, open the air inlet unit, wherein the air inlet door opening is 30%, the heater temperature is 65°C, and hot air is introduced into the granulation chamber;

[0049] (2) The powdered maltitol is transported into the granulation chamber 1 via the feeding unit 4, and the liquid spray unit 5 is opened, so that the binder is transported into the granulation chamber 1 via the liquid spray unit 5 to be mixed with the powdered sugar alcohol. Boiling granulation, wherein the flow rate of the flow meter 52 of the spray unit 5 is 12L / h, and the rotation frequency of the feed rotary valve is 30Hz;

[0050] When the boiling height of the material rises to 55cm, the opening of the pressure difference valve inlet door 21 is controlled to 80%, the temperature of the heater 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com