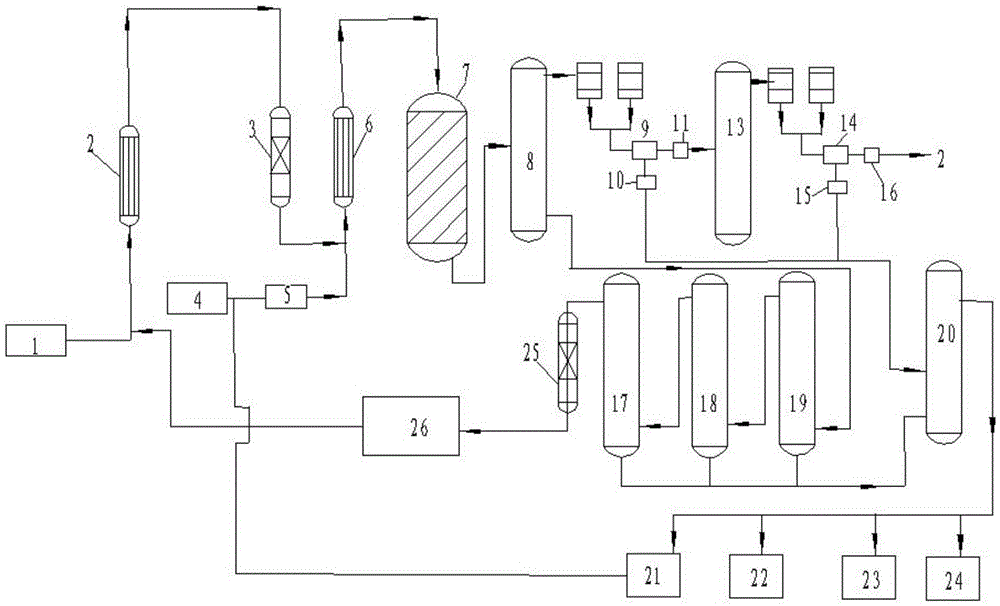

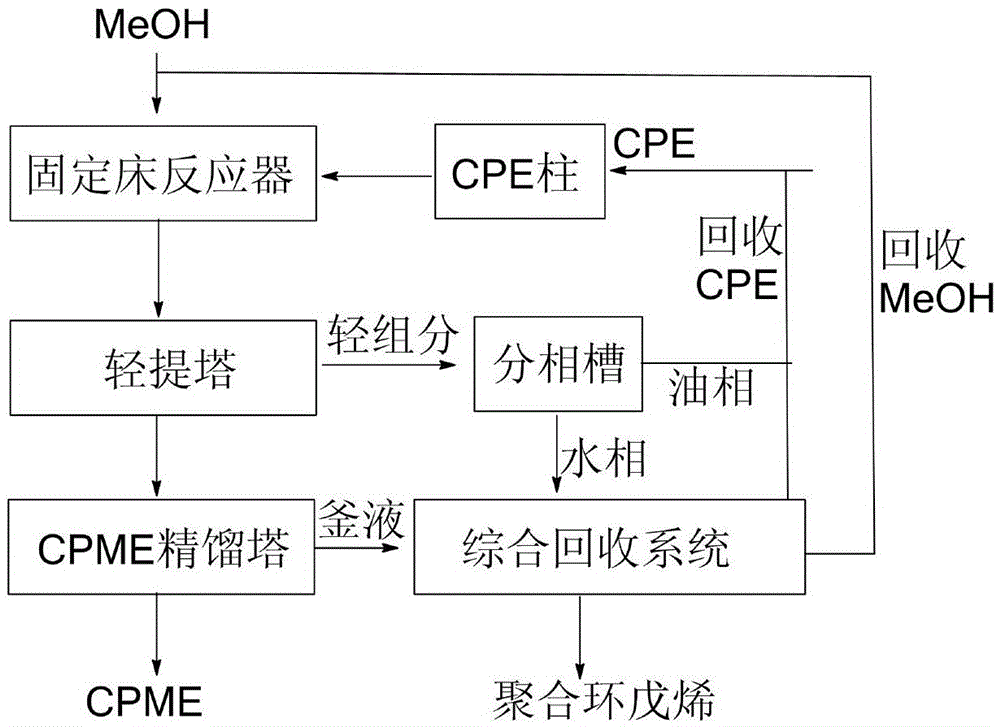

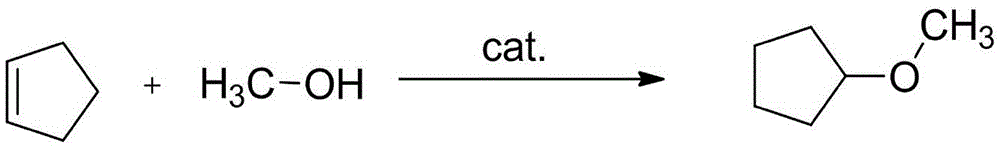

Continuous cyclopentylmethyl ether production process and production system

A technology of cyclopentyl methyl ether and production method, which is applied in the directions of ether preparation, organic chemistry, preparation of ether by addition of unsaturated compounds, etc., can solve the problem of low degree of continuity of cyclopentyl methyl ether production equipment and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] The above system is used for continuous production, the pressure of the vaporized CPE flowing through the adsorption column is 2MPa, 100°C; the particle diameter of amberlyst15 filled in the fixed bed reactor is 1.2-1.8mm; the particle diameter of amberlyst-35 is 0.5-1.2 mm; the specific surface area of amberlyst15 is 30-40m 2 / g, the average pore diameter is 30-40nm, and the total heat exchange capacity is 4.8-5.3eq / L-R. The molar ratio of cyclopentene to methanol is 1.6:1, the temperature of the fixed bed reactor is 100-105°C, and the liquid hourly space velocity is 0.35hr - 1 , the gas hourly space velocity is 110hr -1 ; The pressure is 0.1Mpa. After the continuous production is finished, the conversion rate of methanol is 96%, and the GC purity of the product in the reaction solution is greater than 90% (the purity of the GC area normalization method; sampling every 30min); the purity of the cyclopentyl methyl ether prepared by refining is greater than 99.5%, ...

Embodiment 2

[0075] The above system is used for continuous production, the pressure of the vaporized CPE flowing through the adsorption column is 2MPa, 100°C; the particle diameter of amberlyst15 filled in the fixed bed reactor is 1.2-1.5mm; the particle diameter of amberlyst-35 is 0.5-0.8 mm, the specific surface area of amberlyst15 is 30-40m 2 / g, the average pore diameter is 30-40nm, and the total heat exchange capacity is 4.8-5.3eq / L-R. The molar ratio of cyclopentene to methanol is 1.6:1, the temperature of the fixed bed reactor is 100-105°C, and the liquid hourly space velocity is 0.35hr - 1 , the gas hourly space velocity is 116hr -1 ; The pressure is 0.12Mpa. After the continuous production is finished, the conversion rate of methanol is 97%, and the GC purity of the product in the reaction solution is greater than 93% (the purity of the GC area normalization method; sampling every 30min); the purity of the cyclopentyl methyl ether prepared by refining is greater than 99.5%, ...

Embodiment 3

[0081] Compared with Example 1, the difference is that the vaporized CPE flows through the adsorption column at a pressure of 5 MPa and 90°C. After the continuous production is finished, the conversion rate of methanol is 95%, and the GC purity of the product in the reaction solution is greater than 90% (the purity of the GC area normalization method; sampling every 30min); the purity of the cyclopentyl methyl ether prepared by refining is greater than 99.5%, The overall yield of cyclopentyl methyl ether is greater than 88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com