Recovery method of aluminum electrolysis waste cathode carbon block

A technology of aluminum electrolysis waste cathode and recovery method, which is applied to the preparation/purification of aluminum sulfate, aluminum sulfur compounds, carbon, etc., can solve the problems of difficult recovery of carbonaceous materials, difficult quality assurance, and large acid-base consumption, etc., to achieve Realize clean treatment, realize recycling, and solve the effect of equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

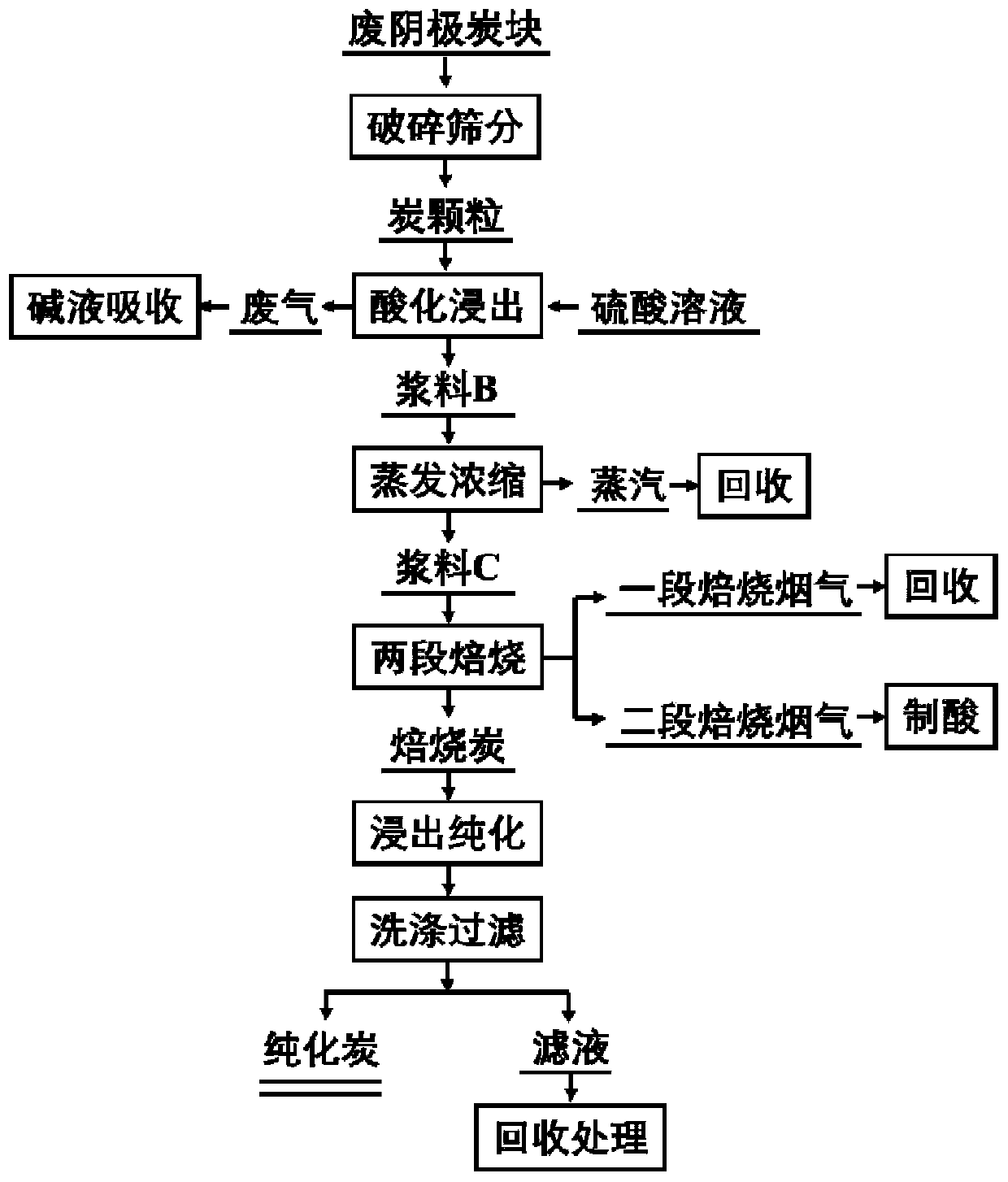

[0058] (1) The cathode carbon block is crushed and sieved to obtain carbon particles;

[0059] (2) Taking the Si element in the carbon particles and the S element in the sulfuric acid solution as the target, after adding the sulfuric acid solution, the Si and S molar ratio in the slurry A is 1:2.10, and the concentration of the sulfuric acid solution is 3mol / L, soaking The time is 5 hours, the temperature is 150°C, and the pressure is 0.4MPa. The gas generated during the process is absorbed with lye.

[0060] (3) Slurry B was evaporated and concentrated at a temperature of 120° C., and the obtained slurry C had a water mass percentage of 8%, and the generated steam was collected to obtain slurry C.

[0061] (4) The F element in the slurry C and the sulfur element in the concentrated sulfuric acid and the slurry C are targeted. After adding the concentrated sulfuric acid, the molar ratio of F and S in the slurry D is 1:1.0, and the concentration of the concentrated sulfuric aci...

Embodiment 2

[0064] (1) Crushing and screening the waste cathode carbon blocks to obtain carbon particles;

[0065] (2) Taking the Si element in the carbon particles and the S element in the sulfuric acid solution as targets, after adding the sulfuric acid solution, the Si and S molar ratio in the slurry A is 1:2.15, and the concentration of the sulfuric acid solution is 2mol / L. The time is 3 hours, the temperature is 200°C, and the pressure is 1.6MPa. The gas generated during the process is absorbed with lye.

[0066] (3) Slurry B was evaporated and concentrated at a temperature of 160° C., and the obtained slurry C had a water mass percentage of 7%, and the generated steam was collected to obtain slurry C.

[0067] (4) The element F in the slurry C, the concentrated sulfuric acid, and the sulfur element in the slurry C are targeted. After adding the concentrated sulfuric acid, the molar ratio of F and S in the slurry D is 1:2.0, and the concentration of the concentrated sulfuric acid is ...

Embodiment 3

[0070] (1) Crushing and screening the waste cathode carbon blocks to obtain carbon particles;

[0071] (2) Taking the Si element in the carbon particles and the S element in the sulfuric acid solution as targets, after adding the sulfuric acid solution, the Si and S molar ratio in the slurry A is 1:2.20, and the concentration of the sulfuric acid solution is 1mol / L, soak The time is 1 hour, the temperature is 250°C, and the pressure is 4MPa. The gas generated during the process is absorbed with lye.

[0072] (3) Slurry B was evaporated and concentrated at a temperature of 180° C., and the obtained slurry C had a water mass percentage of 6%, and the generated steam was collected to obtain slurry C.

[0073] (4) The element F in the slurry C, the concentrated sulfuric acid, and the sulfur element in the slurry C are targeted. After adding the concentrated sulfuric acid, the molar ratio of F and S in the slurry D is 1:3.0, and the concentration of the concentrated sulfuric acid i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com