Clamp for dyeing of cell glass slide

A technology for cell slides and fixtures, applied in the field of fixtures, can solve the problems of changing the effectiveness of reagents, easily damaged cells, and failure of staining, and achieves the effects of simple structure, reduced cell damage, and time saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to fully understand the technical content of the present invention, the technical solution of the present invention will be further introduced and illustrated below in conjunction with schematic diagrams, but is not limited thereto.

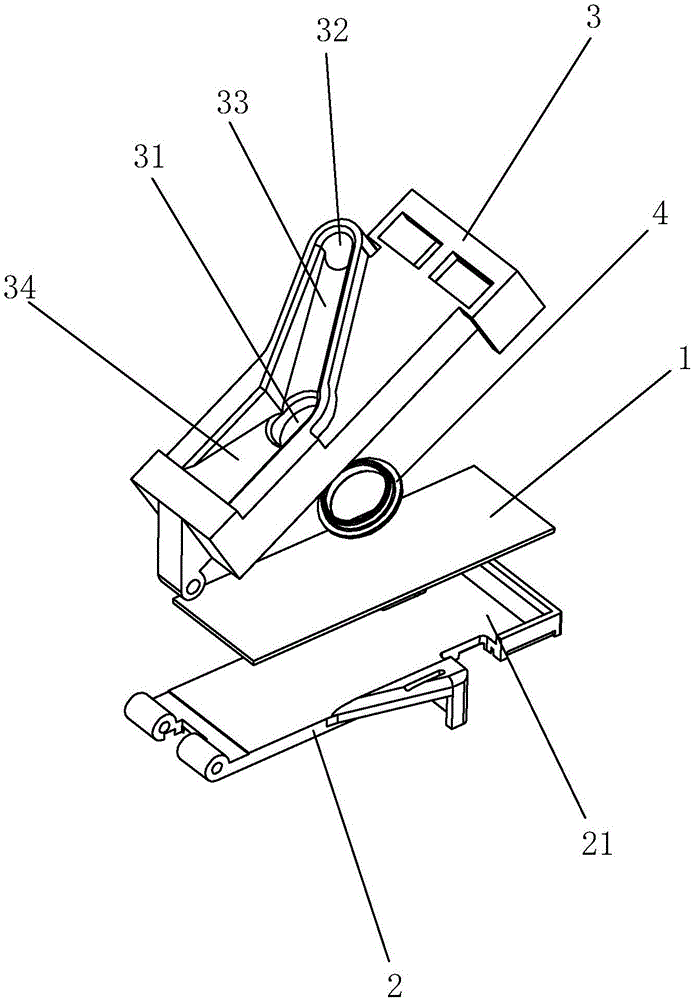

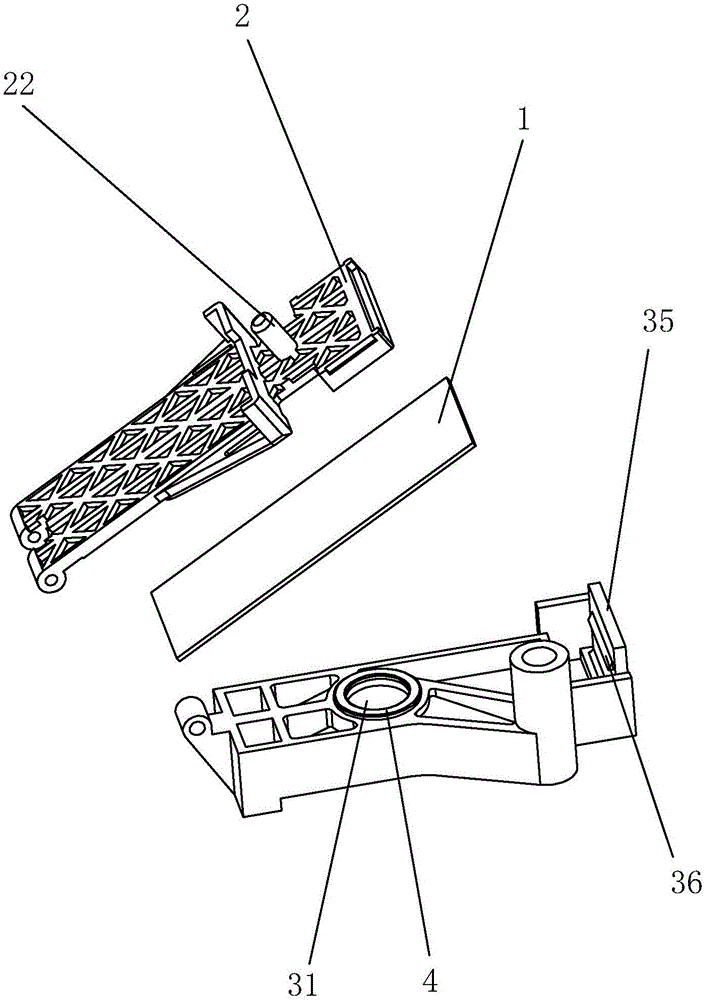

[0032] A fixture for staining cell glass slides, comprising: a carrier for carrying cell glass slides, a pressing member arranged above the carrier and used to compress the cell glass slides on the carrier, the pressing member is provided with a note The liquid pool, the liquid drainage channel, and the liquid guide groove arranged between the liquid injection pool and the liquid discharge channel, the liquid guide groove is inclined upward.

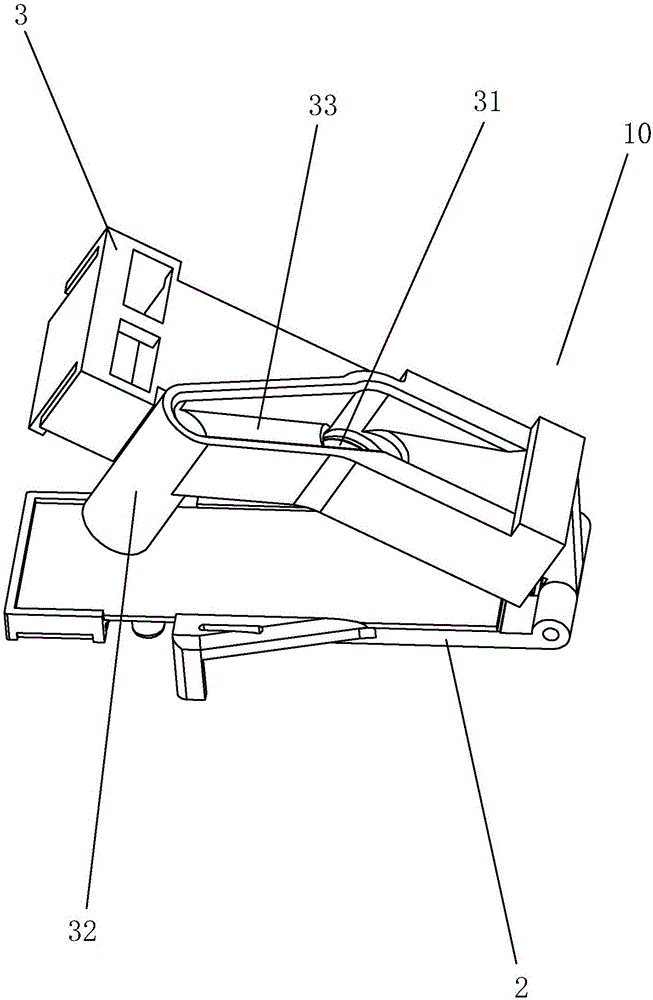

[0033] Such as figure 1 As shown, a fixture 10 for staining cell slides includes: a carrier 2 for carrying cell slides, a pressing member arranged above the carrier 2 and used to compress the cell slides on the carrier 2 3. The bearing part 2 is rotatably connected with the pressing part 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com