Coupled inert gas fire prevention and extinguishing technology in coal mine

An anti-extinguishing and inert gas technology, applied in the direction of fire prevention, dust prevention, mining equipment, etc., can solve the problems of serious air leakage, nitrogen leakage, unreachable, etc., and achieve the effect of cost saving, simple equipment and improved effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

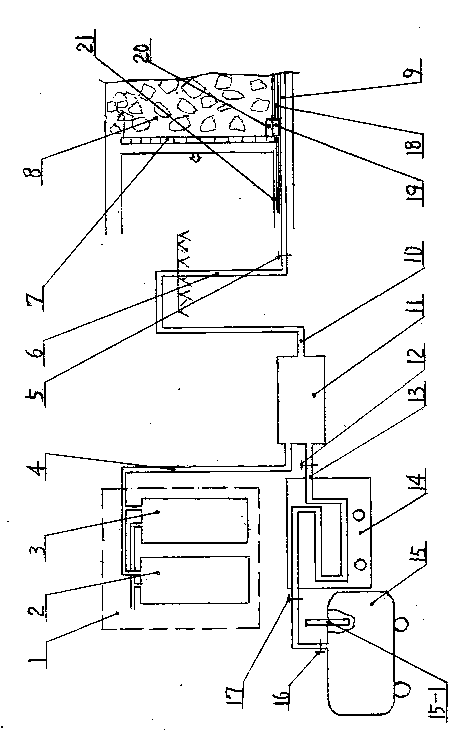

[0009] Examples, see attached figure 1 , Coal mine underground coupled inert gas fire prevention technology firstly according to the coupling inert gas injection flow when inert gas is used for fire prevention and fire extinguishing in the goaf of coal mine, the calculation formula is as follows: Q n =60KeQ 0 (C 1 -C 2 ) / (C n +C 2 -1). In the formula: Q 0 - Air leakage in the oxidation zone of the goaf, generally take 1% of the air volume of the working face; C 1 -Average oxygen content in the oxidation zone in the goaf, C 2 - fire inerting index of goaf oxidation zone, C n -Coupling inert gas purity, K-transport coupling inert gas pipeline loss coefficient is 1.1~1.2, e-fire prevention purposes: 1 for fire prevention, 1.3 for suppressing high-temperature floating coal. The following calculation is based on a specific example: Q 0 : The air volume of the working face is 1400m 3 / min, take Q 0 14m 3 / min;C 1 Take 15%; C 2 Take 7%; C n Take 98%; K takes 1.1; e ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com