Inorganic metal compound, composition comprising inorganic metal compound, device, apparatuses, and manufacturing method for device

A technology of inorganic metals and compounds, applied in the field of light-emitting devices, can solve problems such as fluorescence quenching of quantum dot light-emitting layers, achieve the effects of reducing fluorescence quenching, solving fluorescence quenching, and improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

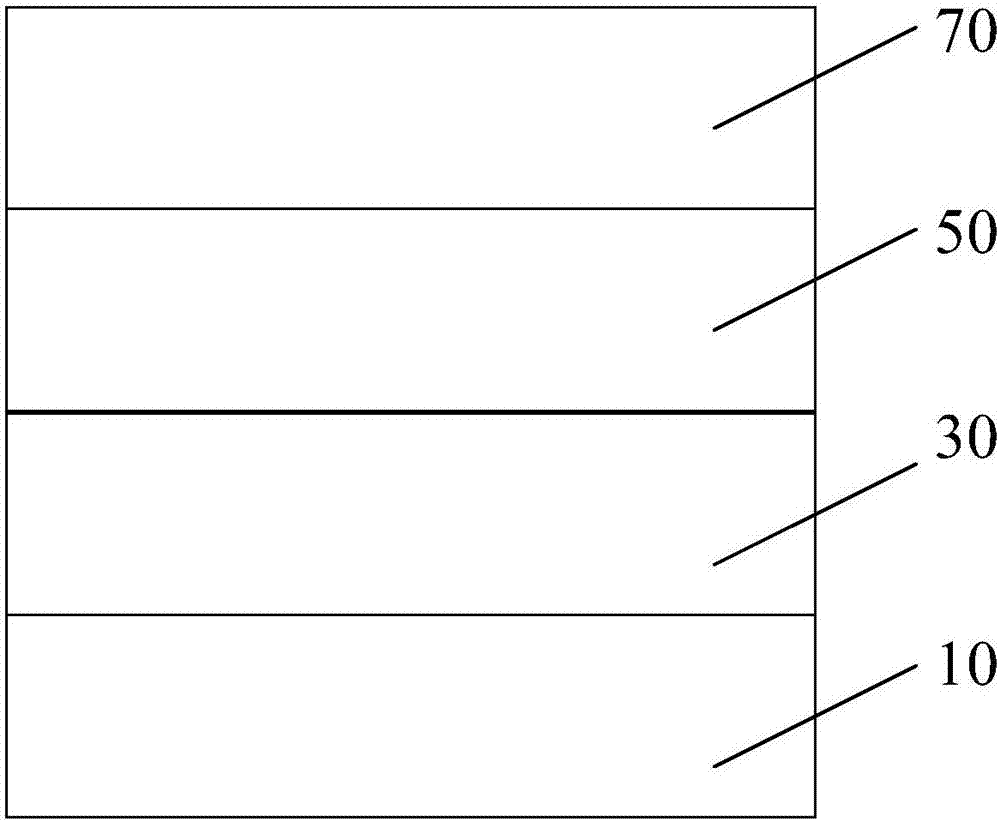

[0075] The fabrication method of the optoelectronic device provided in this embodiment includes the following steps:

[0076] 1) Cleaning the first electrode layer (anode) ITO (indium tin oxide) with a thickness of 200 nm.

[0077] Ultrasonic cleaning with ethanol, deionized water and acetone for 10 min, followed by N 2 Dry the liquid adhering to the surface of the glass, and undergo ozone-ultraviolet treatment for 10 minutes to remove impurities on the surface of the ITO.

[0078] 2) Fabricate the first carrier injection layer.

[0079] In an air environment, spin-coat PEDOT:PSS (polystyrene sulfonic acid solution) on a clean ITO transparent conductive glass at a speed of 3000 rpm for 45 seconds. After the spin coating is completed, it is annealed at 140° C. for 30 minutes in the air. Then transfer it to a glove box in a nitrogen atmosphere, anneal at 100°C for 40 minutes, and finally form a PEDOT:PSS layer on the surface of ITO, that is, form the first carrier injection l...

Embodiment 2

[0091] The difference between the preparation method provided by this embodiment and Example 1 is:

[0092] Step 3) In the step of making the first carrier transport layer, the synthesized inorganic semiconductor nanocrystal is ZnO nanocrystal, and its specific synthesis method is: 3mmol zinc acetate dihydrate and 30ml DMSO (dimethyl sulfoxide) Add it into a 100ml three-necked flask, heat it in a water bath at 30°C and stir it magnetically. Take another small beaker, add 5mmol TMAH (tetramethylammonium hydroxide) and 10ml ethanol, shake well and mix well, and then seal it with a sealing film; add solution B dropwise to solution A, then continue magnetic stirring, at 30 ° C under a water bath environment and stirred for 1 hour to form inorganic semiconductor nanocrystal ZnO, and then purify the inorganic semiconductor nanocrystal ZnO.

[0093] After the inorganic semiconductor nanocrystal ZnO after above-mentioned purification is made into the normal hexane solution of 10mg / ml...

Embodiment 3

[0096] The difference between the preparation method provided by this embodiment and Example 1 is:

[0097] The molar ratio of the inorganic semiconductor nanocrystals to the chelating agent is 10:1, that is, the above-mentioned inorganic semiconductor nanocrystals NiO are made into a 10 mg / ml n-hexane solution and then 0.5 mmol of the chelating agent is added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com