Ion exchange film fuel cell dipole plate and application thereof

A technology of ion exchange membranes and fuel cells, which is applied in the direction of fuel cells, fuel cell groups, fuel cell components, etc., can solve problems such as complex structure, unstable electrical performance, and difficult processing, and achieve the effect of simplifying the integrated system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

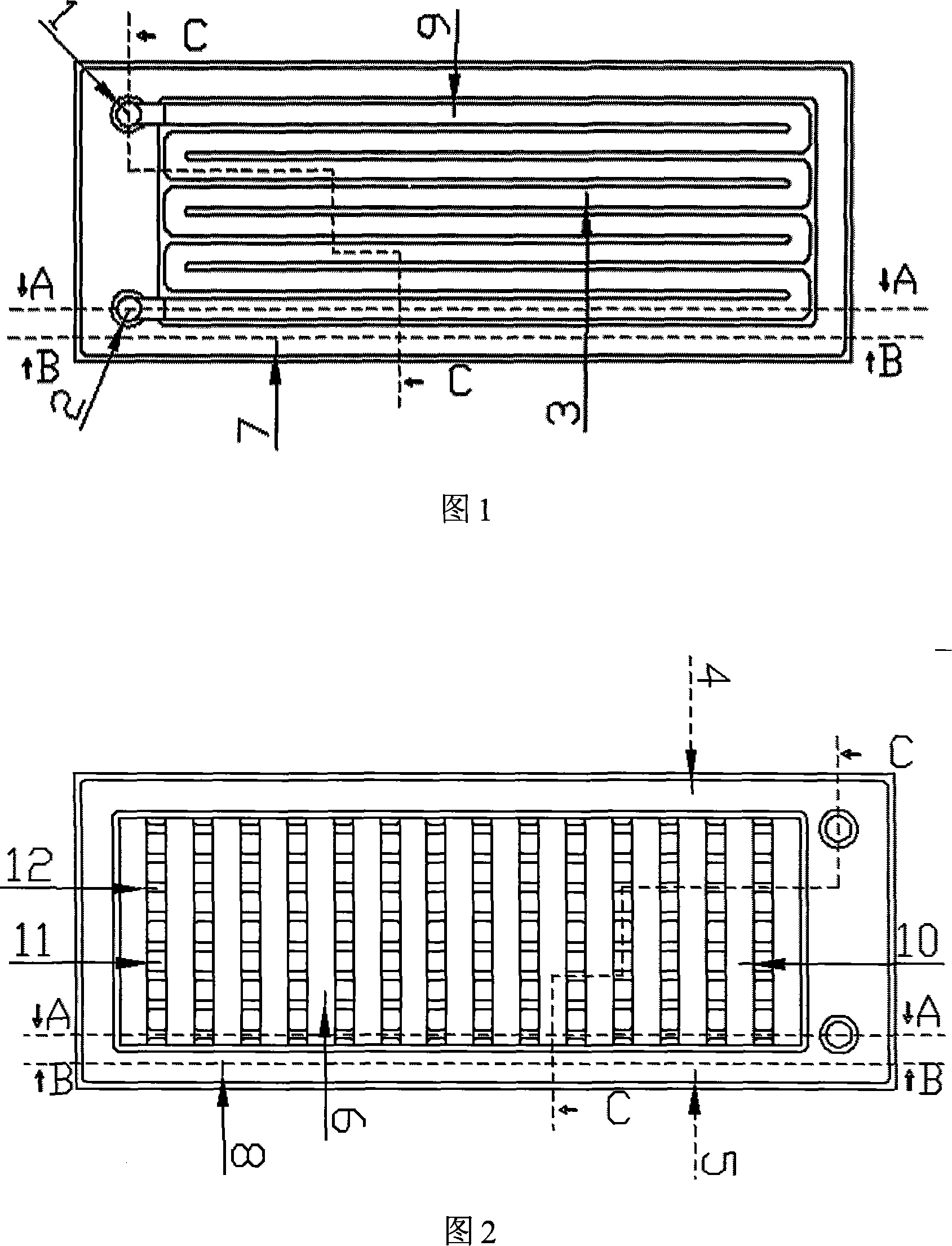

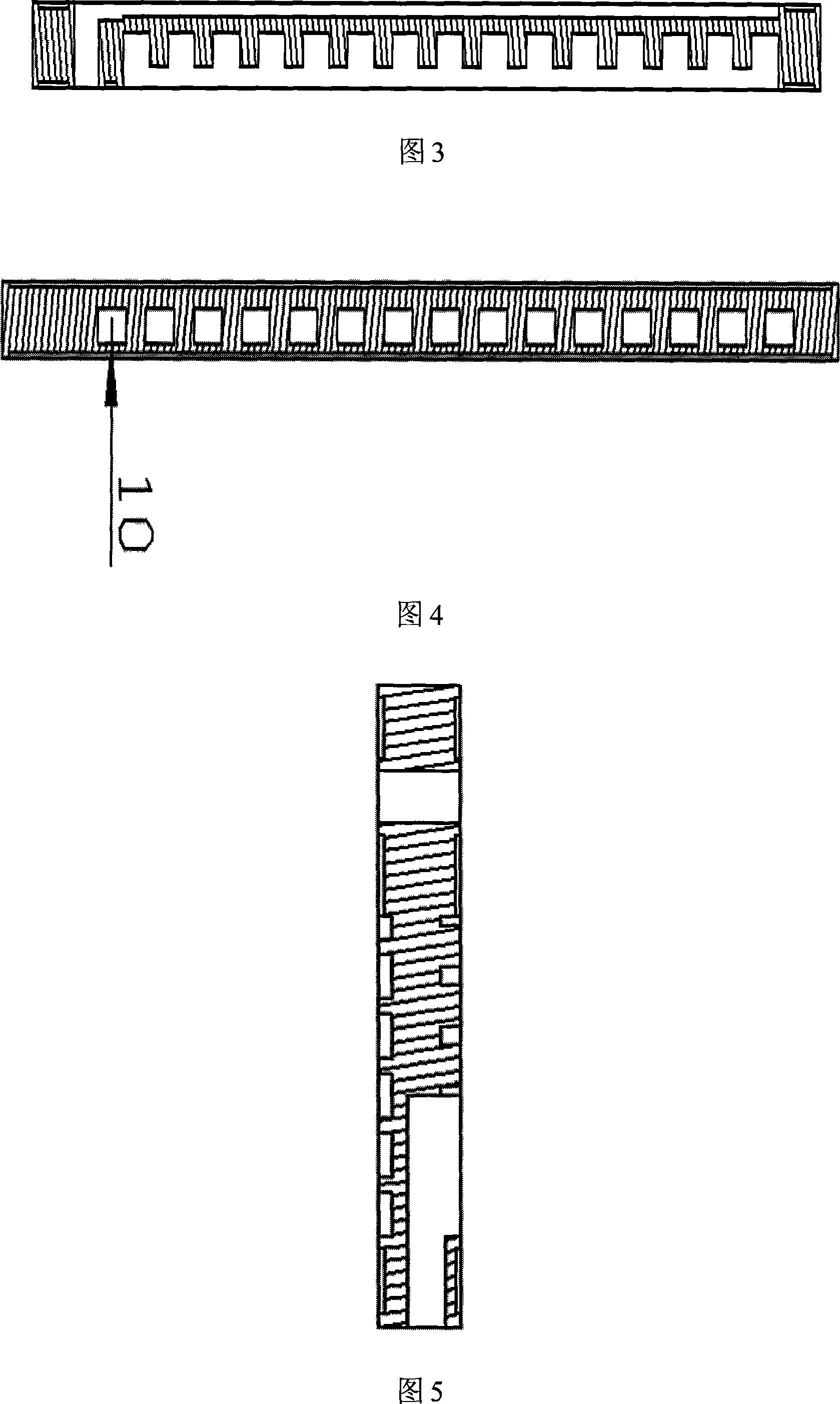

[0044] A graphite plate is used to shape the above bipolar plate in an engraving manner, and the effective area is 54mm×18mm. The fuel flow channel 9 is serpentine. The oxidant inlet 4 and the oxidant outlet 5 are both square in shape and equal in number.

Embodiment 2

[0046] The graphite plate is used to form the above bipolar plate by machine tool processing, and the effective area is 80mm×30mm. The fuel flow channel 9 is serpentine with a width of 1.5 mm and a depth of 0.5 mm. The oxidizing agent channel 10 has a width of 1.5mm and a depth of 1.5mm. The single hole area of oxidant inlet 4 and oxidant outlet 5 is 2mm 2 , are all square in shape and equal in number. The depth of the sealing groove 7 is 0.2 mm. The moisture retention groove 12 has a width of 0.5mm and a depth of 0.2mm.

Embodiment 3

[0048] The expanded graphite plate is used to shape the bipolar plate by machine tool processing, and the effective area is 50mm×20mm. The fuel flow channel 9 is checkerboard-shaped, with a width of 2 mm and a depth of 0.5 mm. The oxidant channel 10 has a width of 2mm and a depth of 1.5mm. The single hole area of oxidant inlet 4 and oxidant outlet 5 is 2.5mm 2 , are all circular in shape and equal in number. The depth of the sealing groove 7 is 0.3mm. The moisture retention groove 12 has a width of 0.8 mm and a depth of 0.2 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com