Production method of dichlorosilane for preparing silane

A technology of dichlorodihydrogen silicon and a production method, which is applied in the directions of halogenated silanes, halogenated silicon compounds, etc., can solve the problem of reducing the separation efficiency of the rectifying tower, unbalanced gas-liquid distribution of the rectifying tower, and increasing the design and manufacture of the rectifying tower. Difficulty and other problems, to achieve the effect of high boiling point, easy recycling and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

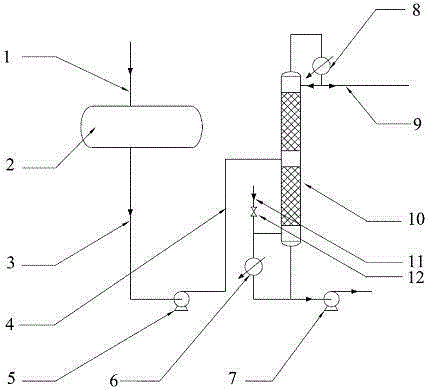

[0025] use as figure 1 In the rectification tower shown, in the crude trichlorosilane raw material storage tank 2, trichlorosilane is added through the feed pipe 1, and the trichlorosilane is transported into the rectification tower 10 through the pump 5, and the gas at the top of the tower is passed through Part of the reflux enters the rectification tower 10 after the cooling of the tower top cooler 8 of the rectification tower 10, and the part is taken out as the purified dichlorodihydrosilane product, and the ionic liquid in the tower still reboiler 6 of the rectification tower 10 After the trichlorosilane and silicon tetrachloride are mixed, they are taken out and recovered by the pump 7, and the recovered ionic liquid is added to the rectification tower still 6 as a supplementary catalyst, and the trichlorosilane is returned to the storage tank 2 as a raw material.

[0026] In the above scheme, the ionic liquid cation used is hexyltriethylammonium ion, the anion is N(CN)...

Embodiment 2

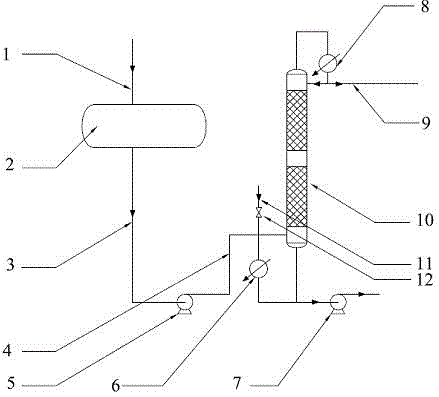

[0028] use as figure 2 In the rectification tower shown, in the crude trichlorosilane storage tank 2, trichlorosilane is added through the feed pipe 1, and the trichlorosilane is transported into the rectification tower 10 through the pump 5, and the gas at the top of the tower is refined The top cooler 8 of the distillation tower 10 cools and partly refluxes into the rectification tower 10, partly takes out as the purified dichlorodihydrosilane product, and the three ions containing the ionic liquid in the tower kettle reboiler 6 of the rectification tower 10 After the silicon chloride and silicon tetrachloride are mixed, they are taken out and recovered by the pump 7, and the recovered ionic liquid is added to the rectification tower still 6 as a supplementary catalyst, and the trichlorosilane is returned to the storage tank 2 as a raw material.

[0029] In the above scheme, the ionic liquid cation used is 1-ethyl-3-methylimidazolium ion, the anion is (C2F5SO2)2N-, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com