Method for preparing open-cell foam titanium

A technology of open-cell foam and titanium powder, which is applied in the field of titanium foam materials, can solve problems such as the production rate of foam titanium is less than 20%, collapse, fracture, etc., and achieves the effects of low cost, increased output rate, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

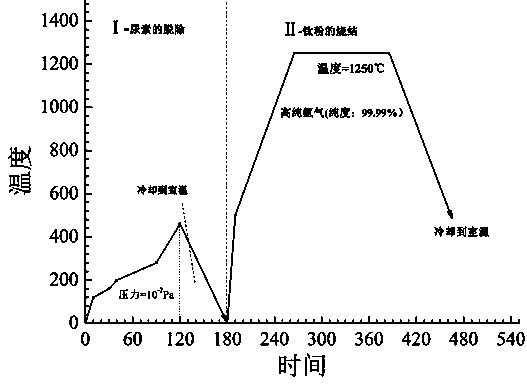

[0031] Example 1: A method for preparing open-cell titanium foam, comprising the steps of:

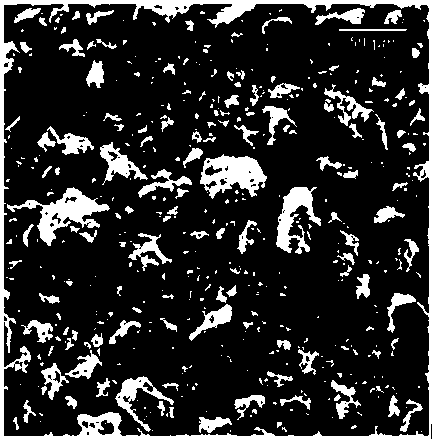

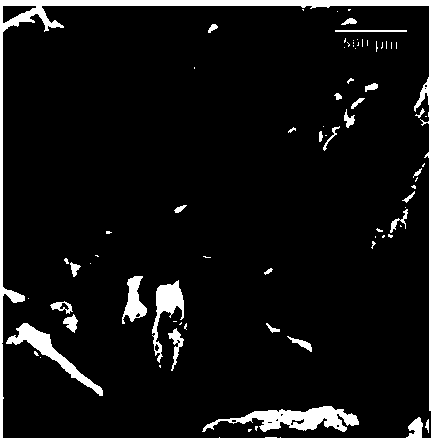

[0032] 1) Mixing of raw materials, select high-purity titanium powder and needle-shaped urea with an average particle size of 225 μm and mix them in the research body to obtain a preliminary

[0033] The average particle size of high-purity titanium powder is 32 μm, the titanium content and oxygen content are 99.3% and 0.5%, respectively, and the average particle size of acicular urea is 398 μm, and the volume fraction of acicular urea in the preliminary mixture is 60 vol.%, the rest is high-purity titanium powder;

[0034] 2) Put the preliminary mixture obtained in step 1) on a steel abrasive tool (the steel abrasive tool is a cylinder, and the bottom of the cylinder is

[0035] The surface diameter is 16mm; the height is 50mm), and the cylindrical green compact is pressed under the press, where the unidirectional pressure is 150MPa, the moving speed of the indenter is 1.5 mm / min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com