Preparation method of unfired glazed aluminum alloy curtain wall plate

A technology of aluminum alloy and curtain wall panels, applied in the direction of surface coating liquid devices, walls, adhesive types, etc., can solve the problems of high energy consumption, non-compliance, etc., and achieve long life, reduced energy consumption, and less equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

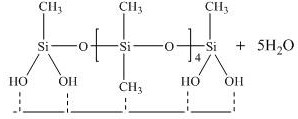

Method used

Image

Examples

Embodiment 1

[0023] First of all, prepare the adhesive, the proportion is 7phr polyvinyl alcohol 17-88, water 30phr, additive sodium methyl silicate 15phr, stir and mix for 0.6h, the mixture is poured into two parts by weight in the stirring tank Add 150 parts of sodium naphthalene disulfonate, then add 800 parts of water at 80°C, and mix well to obtain a sodium dinaphthyl methanedisulfonate solution. Take 50 parts of ammonium aluminum sulfate, put it in an insulated container, add 900 parts of water at 80°C, and then , then add 60 parts of the obtained sodium dinaphthyl methane disulfonate solution, mix well to obtain a mixed solution of ammonium aluminum sulfate-sodium di-naphthyl methane disulfonate, dilute the mixed solution of ammonium aluminum sulfate-sodium di-naphthyl methane disulfonate with clear water 9 times, the mixture is obtained; secondly, use a clean aluminum plate made of 3003 alloy in H24 state, with a thickness of 2.0mm, a width of 1500mm, and a length of 4000mm, wipe th...

Embodiment 2

[0026]First, prepare the adhesive, the proportion is 7 parts of polyvinyl alcohol 17-88, 10 parts of water, 8 parts of additive trisodium phosphate, stir and mix for 0.5h, the mixture is poured into two parts by weight in the stirring tank Add 148 parts of sodium naphthalene disulfonate, then add 800 parts of clear water at 60°C, and mix well to obtain a sodium dinaphthyl methane disulfonate solution. Take 40 parts of ammonium aluminum sulfate, put it in an insulated container, add 900 parts of clear water at 60°C, and then , then add 55 parts of the obtained sodium dinaphthyl methane disulfonate solution, mix well to obtain the mixed solution of ammonium aluminum sulfate-sodium di-naphthyl methane disulfonate, dilute the mixed solution of ammonium aluminum sulfate-sodium di-naphthyl methane disulfonate with clear water 8 times, that is, the mixture; secondly, use a clean aluminum plate made of 3003 alloy in H24 state, with a thickness of 2.0mm, a width of 1500mm, and a length ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com