Preparation and construction method of brick-concrete building waste residue recycled road base inorganic mixture

A technology for building waste residue and road base, which is applied in the field of preparation and construction of inorganic mixture for reclaiming road base from brick-concrete building waste, can solve the problems of complex processing technology, pollute the environment, low utilization rate, etc., and achieves simple technical process and protection. The effect of ecological environment and high utilization rate of waste residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

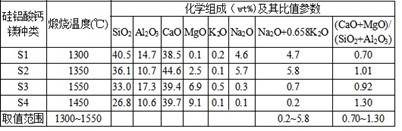

[0015] Sorting and pretreatment of construction waste first, removing organic matter such as wood, rubber, plastic, asphalt, cloth fiber and domestic waste, and metal materials such as steel bars. The remaining waste is mainly composed of waste clay bricks, waste concrete, and broken mortar. Composed of flakes and a small amount of glass ceramics, etc., it belongs to brick-concrete construction waste, and the latter is multi-stage crushed to obtain recycled sand powder with a particle size of no more than 4.75mm. Mixed kaolin mixed with 1.5% caustic soda and calcined at 750°C for 3 hours, then cooled naturally to obtain metakaolin, ground it finely, and measured its Blaine specific surface area to be 455m 2 / kg; 4 kinds of raw materials mainly containing oxides of silicon, aluminum, calcium and magnesium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com