Double screw dehydrating equipment capable of realizing dehydrating, drying and puffing processes

A technology of puffing process and dehydration equipment, which is applied in the direction of manufacturing tools, chemical instruments and methods, separation methods, etc., can solve the problem of low production efficiency of filter press, achieve the effect of improving effect and production efficiency, and occupying a small area of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

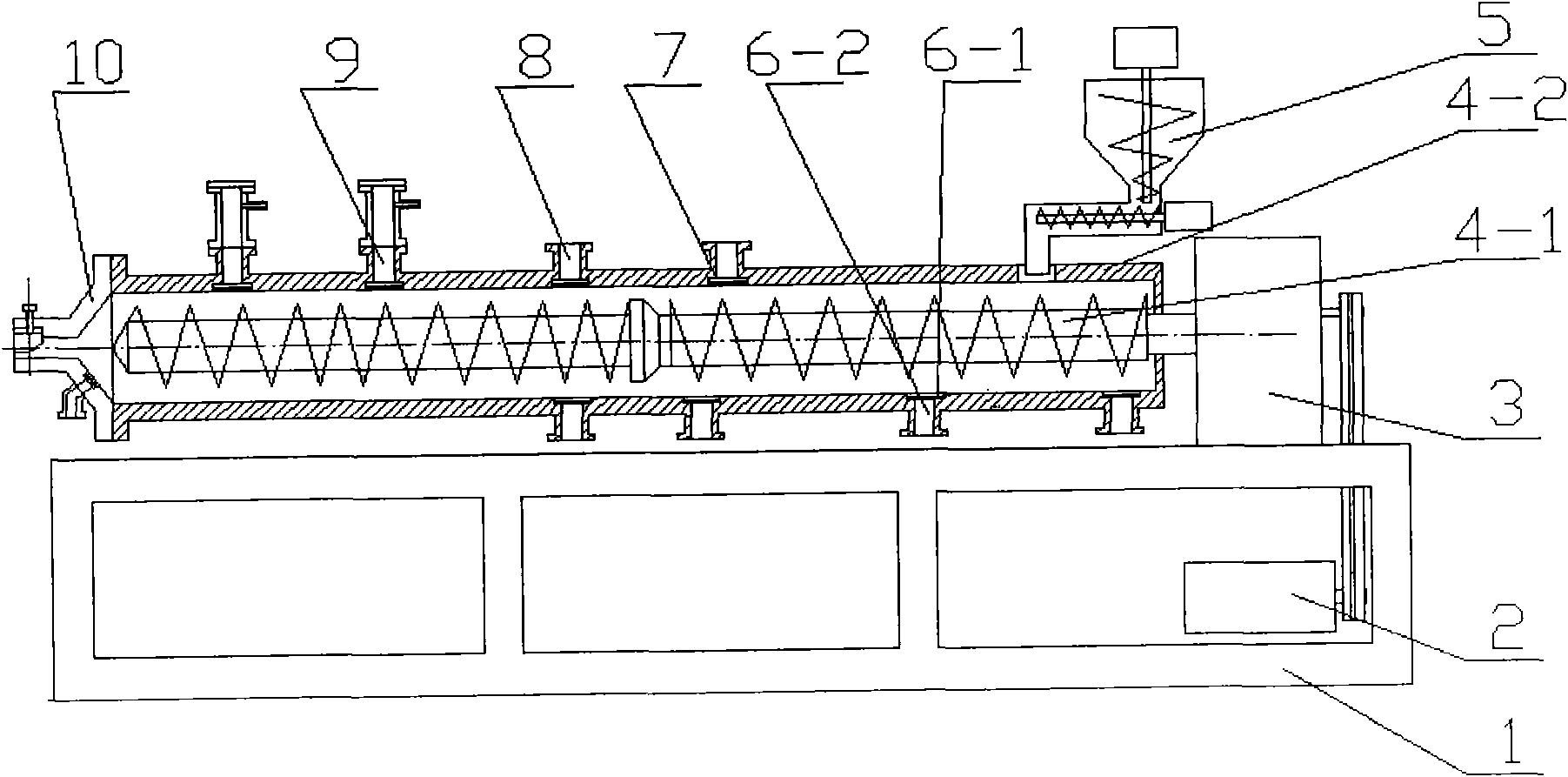

Embodiment 1

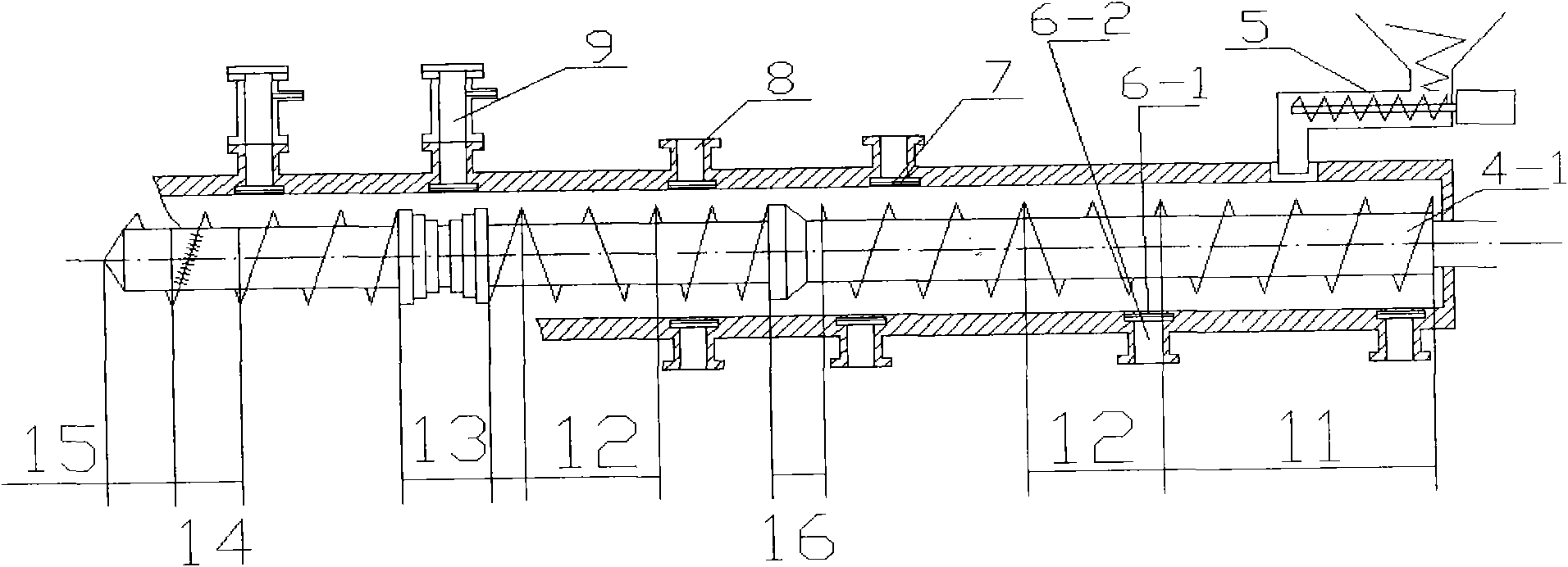

[0028] figure 2 is an embodiment of the present invention. Frame 1, motor 2, reduction gear mechanism 3, feeding barrel 4-2 and head pressure control device 10 are not drawn in the figure. The equipment is fixed on the frame 1, the power source motor 2 is connected with the reduction gear mechanism 3 through the transmission device, and the output shaft of the reduction gear mechanism 3 is connected with the double screw 4-1 in the screw barrel pair through a spline sleeve or a coupling Connection, the dehydration barrel, the normal pressure exhaust barrel and the negative pressure exhaust barrel are connected by bolts among the barrel parts in the barrel pair, and the barrel pair can also be designed as an integral type. Open holes in different positions and install dehydration media, which are used as exhaust and dehydration holes. The head pressure control device is connected with the barrel pair by bolts. The twin-screw 4-1 is composed of screw mandrel, forward thread ...

Embodiment 2

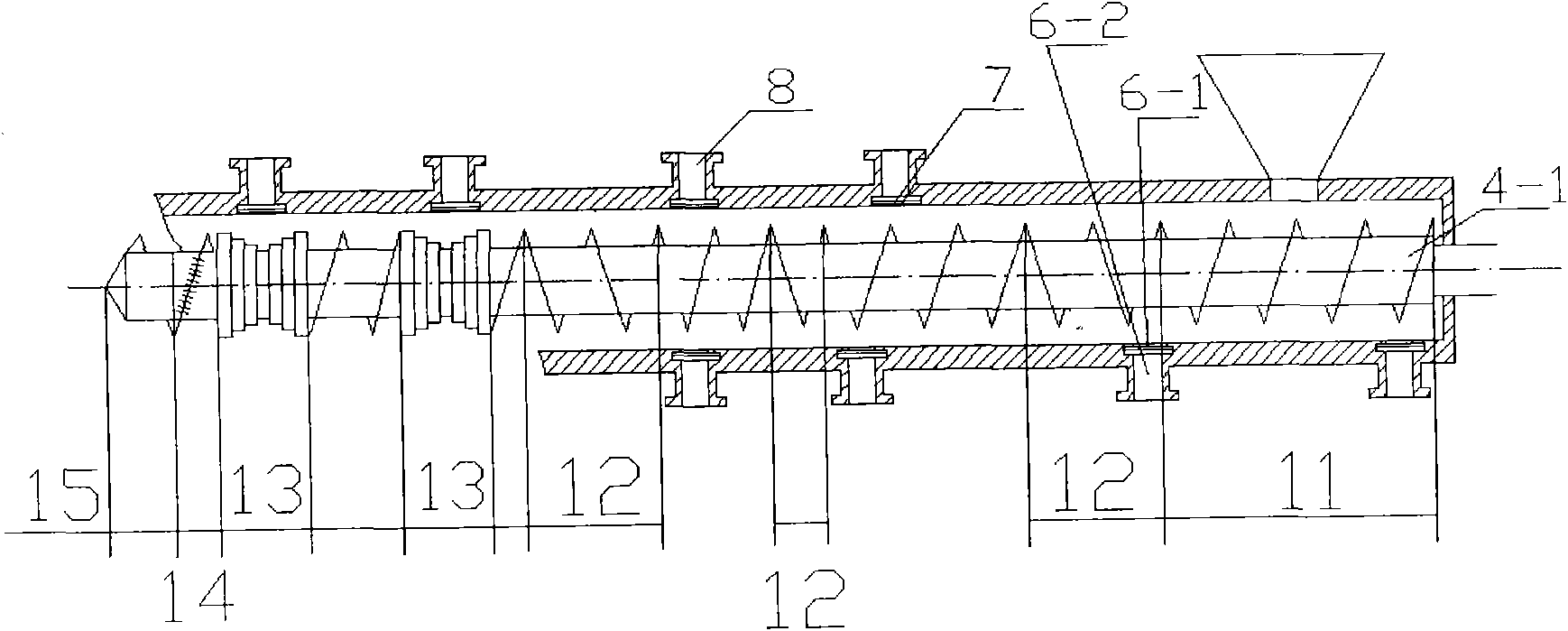

[0032] image 3 It is another embodiment of the present invention, which is used for dehydration and expansion of water-containing materials with good fluidity. There is no feeding device at the screw inlet, and gravity feeding is used. In the first area of the screw, the damping element is replaced by a reverse thread, and a reverse thread element is added, which is equivalent to increasing the first area of the screw. The corresponding barrels in the second and third areas of the screw are replaced by negative pressure exhaust barrels with normal pressure exhaust barrels, and kneading block elements are set at the exhaust holes to facilitate smooth exhaust and reduce power consumption . All the other screw thread elements and barrel configurations are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com