A single-screw dehydration, drying and puffing equipment

A puffing equipment and single-screw technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problem of low production efficiency of filter presses, achieve the effect of improving the effect and production efficiency, and the equipment occupies a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

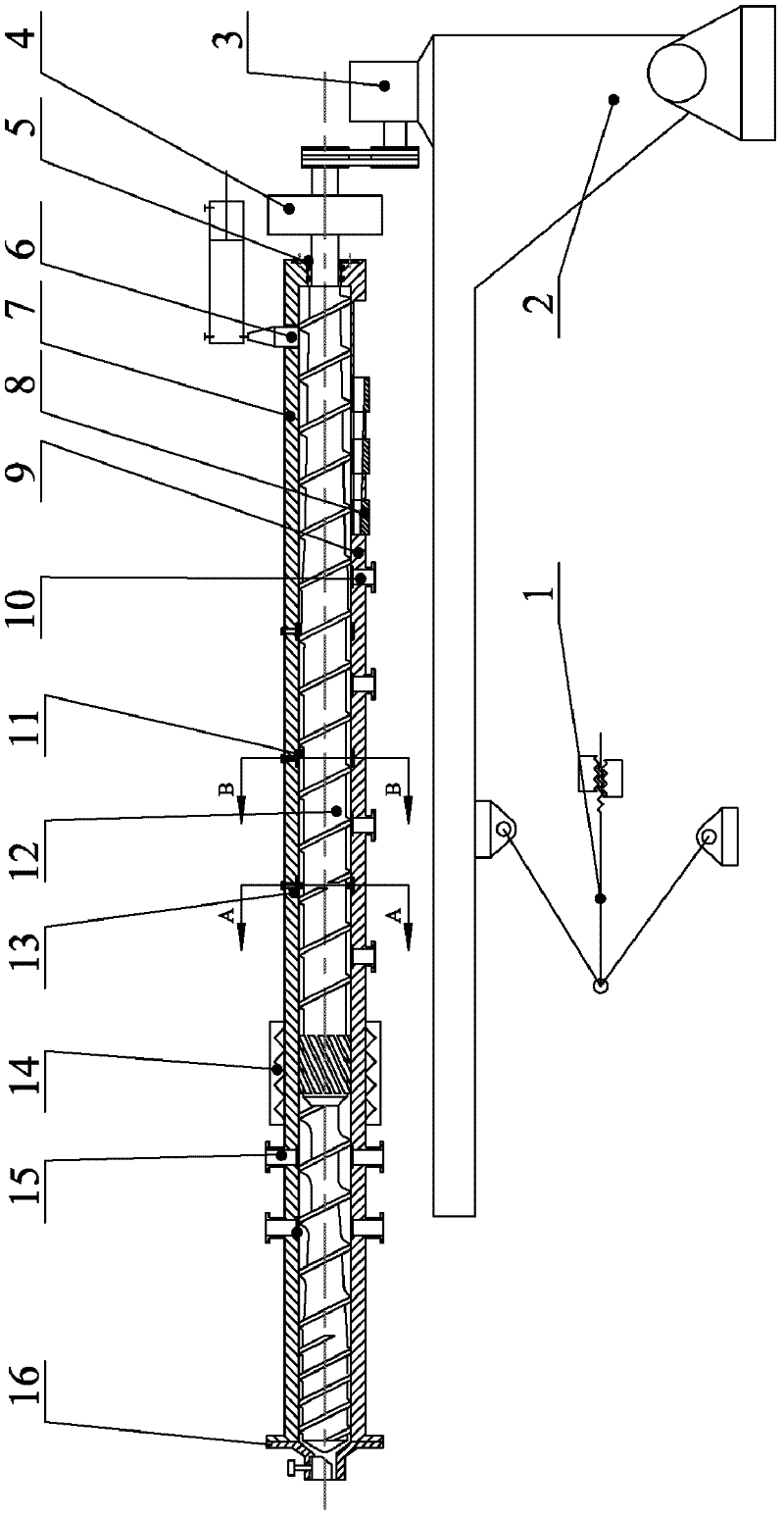

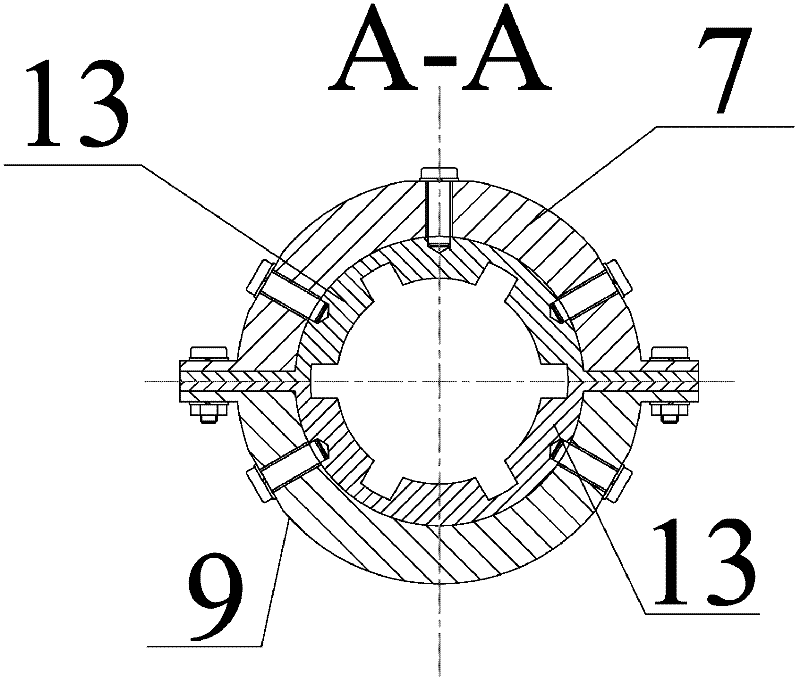

[0029] figure 1is an embodiment of the present invention. One end of the frame adjustment device is fixed to the ground, and the other end is fixed on the frame, which is used to adjust the pitch angle of the frame. The motor, the reduction gear mechanism and the barrel pair are fixed on the frame. When the frame adjustment mechanism adjusts the pitch angle of the frame, the equipment changes the pitch angle along with the frame. The motor is connected with the reduction gear mechanism through the transmission device, and the output shaft of the reduction gear mechanism is connected with the separating screw rod installed in the machine barrel through a spline sleeve or a shaft coupling. There is a feeding port on one side of the barrel, which is used to send the water-containing material to the inside of the barrel for dehydration. The other side of the barrel pair is connected with the head pressure control device, which controls the pressure of the water-containing materi...

Embodiment 2

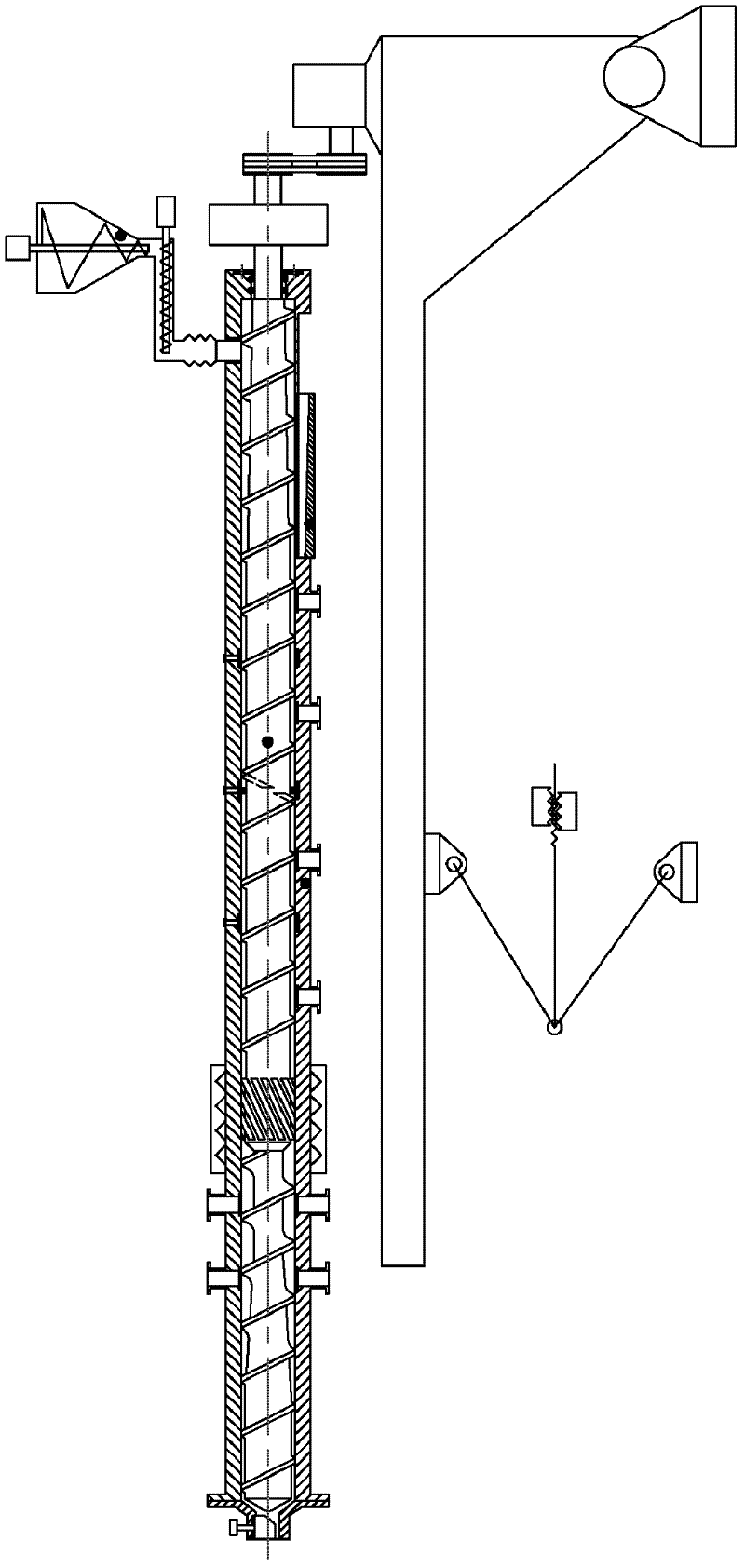

[0037] figure 2 It is embodiment 2 of the present invention. The difference between embodiment 2 and embodiment 1 is that in embodiment 2, an integrated filter screen is used at the outlet 8 in order to increase the filter area of press dehydration and improve the dehydration efficiency. The integrated filter screen extends from the feeding port to the end of the screw press dehydration section, and there are no less than two rows. And use the screw forced feeding device. At the same time, the thread disconnection position of the single-threaded screw section of the separation screw used in this embodiment is the position matching the barrier block of the barrel, which is different from the separation screw 1 and is relatively behind. In order to save manufacturing costs, the double-flight screw section of the screw is canceled and replaced with a single-flight screw section. The feeding method of Example 2 is also different from that of Example 1. A screw forced feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com