Refining agent for copper and copper alloy smelting

A refining agent and copper alloy technology, which is applied in the composition and preparation of refining agents for new copper and copper alloy smelting, can solve the problems of high-quality copper and copper alloy products, reduced copper conductivity, and expensive lithium melts and other problems, to achieve the effect of accelerating adsorption and inclusion capacity, high surface tension, and ensuring composition and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

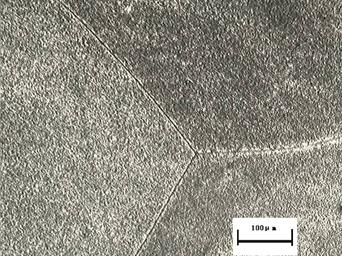

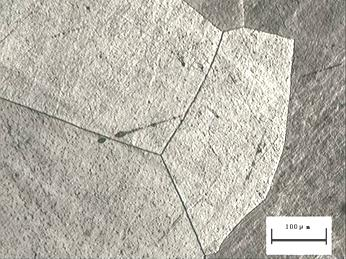

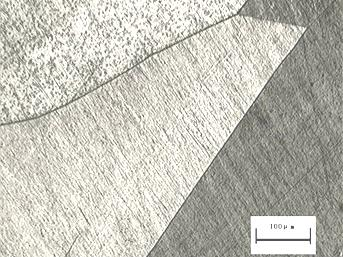

Image

Examples

Embodiment 1

[0026] According to 10 wt.% calcium fluoride, 2.5 wt.% silicon dioxide, 2.5 wt.% titanium dioxide, 4 wt.% sodium fluorosilicate, 46 wt.% sodium carbonate, the balance is the weight of sodium tetraborate The percentages are used to prepare the refining agent of the present invention.

[0027] After mixing the above refining agents evenly, put them into the drying box, at 120 o C, dry for one hour; then use a metallographic inlay machine to manually press the refining agent of the present invention into a sheet; wrap it with copper foil for future use.

Embodiment 2

[0030] According to 10 wt.% calcium fluoride, 2.5 wt.% silicon dioxide, 2.5 wt.% titanium dioxide, 10 wt.% sodium fluorosilicate, 40 wt.% sodium carbonate, the balance is the weight of sodium tetraborate The percentages are used to prepare the refining agent of the present invention.

[0031] The refining agent preparation and use process are the same as in Example 1.

Embodiment 3

[0033] According to 10 wt.% calcium fluoride, 2.5 wt.% silicon dioxide, 2.5 wt.% titanium dioxide, 2 wt.% sodium fluorosilicate, 48 wt.% sodium carbonate, the balance is the weight of sodium tetraborate The percentages are used to prepare the refining agent of the present invention.

[0034] The refining agent preparation and use process are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com