Apple juice and preparation method thereof

A technology of apple juice and apples, applied in the field of apple juice and its preparation, which can solve the problems of complex preparation of preservatives, nutritional damage of apple juice, loss of flavor, etc., to maintain flavor and nutrients, reduce enzymatic change and browning, VC The effect of loss below

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

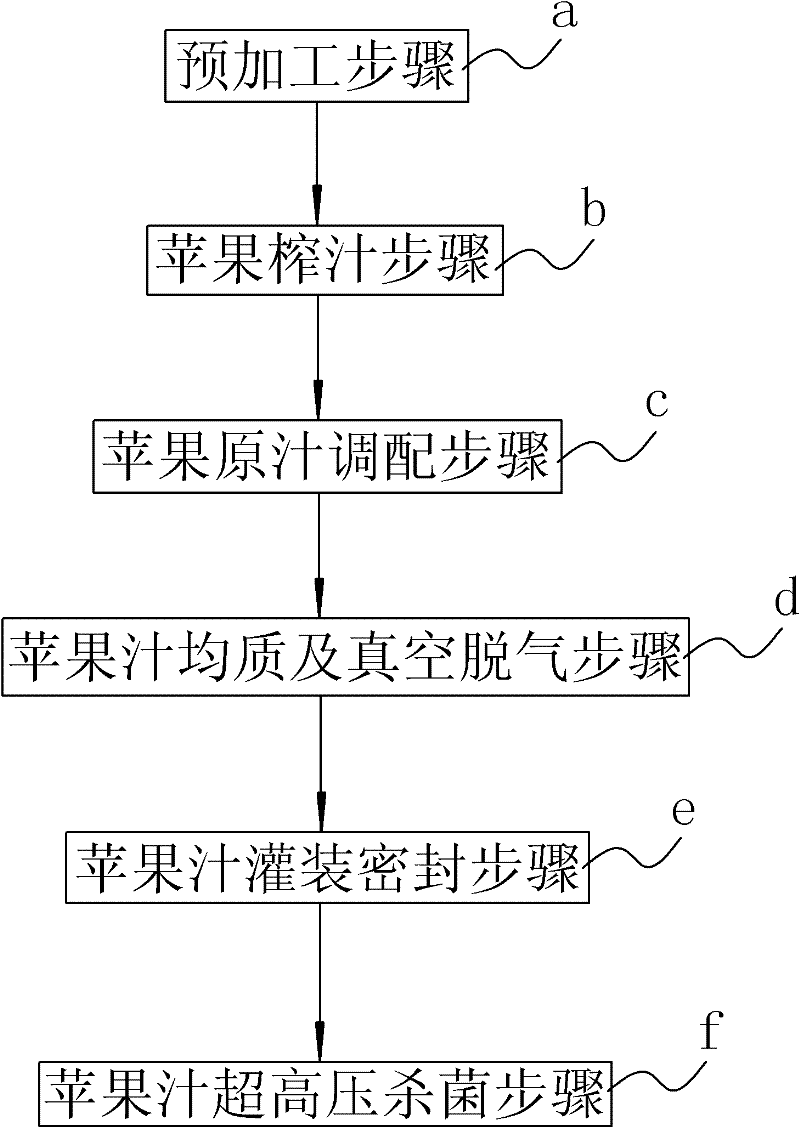

[0040] see figure 1 , figure 1 It is a flow chart of the preparation method of the present invention. The preparation method of apple juice of the present invention, comprises the steps:

[0041] a. Preprocessing steps;

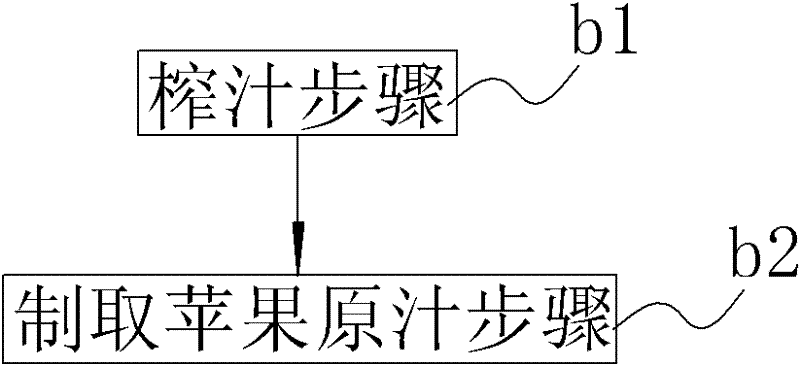

[0042] b, apple juice step;

[0043] c, apple juice deployment steps;

[0044] d, apple juice homogenization and vacuum degassing steps;

[0045] e. Apple juice filling and sealing steps;

[0046] f, apple juice ultra-high pressure sterilization step.

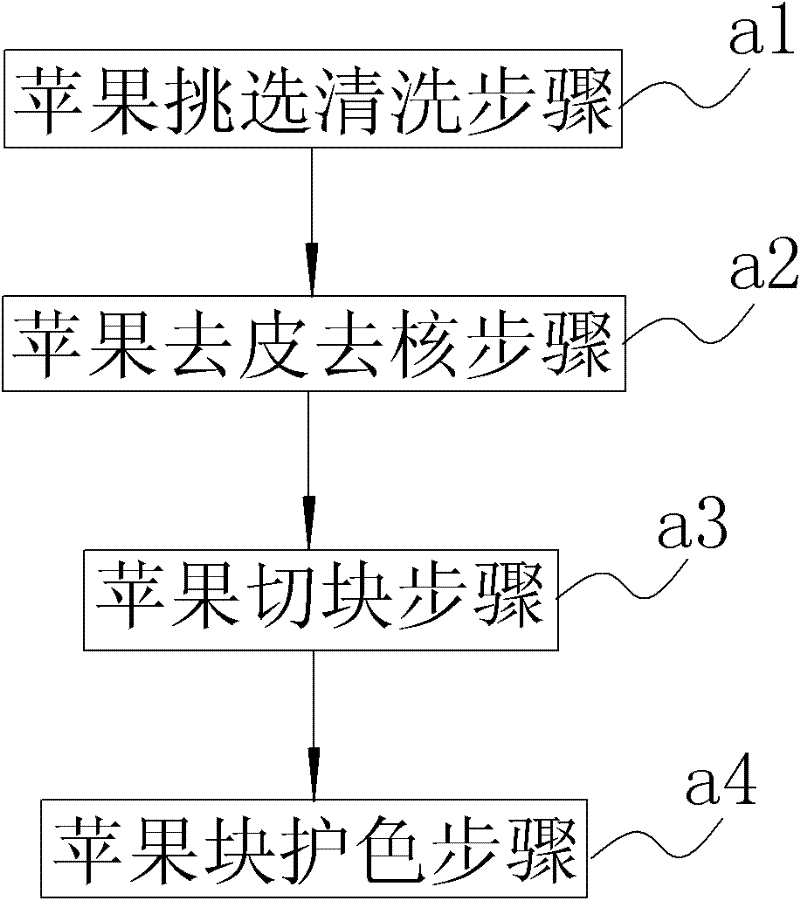

[0047] see figure 2 , figure 2 It is a flow chart of preprocessing steps in an embodiment of the present invention. Wherein, the preprocessing step a includes:

[0048] a1. Apple selection and cleaning steps: select fresh, complete fruit shape, uniform maturity and size, and no pests, no damage, no rotten apples, rinse the surface of the apples with clean water, and remove the silt and impurities on the surface;

[0049] a2, apple peeling and core removal step: the cleaned apples are peeled and co...

Embodiment 1

[0068] Select fresh apples with complete fruit shape, uniform maturity and size, no pests, no damage, and no rot. Rinse the apples with clean water to remove the sediment and impurities on the surface; use a special manual peeling knife or mechanical peeling to eliminate The thickness of the peel is within 1.2mm. Cut in half longitudinally along the suture line with a knife, and the cut surface should be smooth. Then use a knife to remove the core and handle, and keep the length of the cut at 20mm. Soak in a mixed aqueous solution of 0.1% VC and 0.1% citric acid for 10 minutes to protect the color.

[0069] Drain the color-protected apple pieces and put them in a press to squeeze the juice. The squeezed slurry was filtered through a centrifugal filter (300r, 20min) with a sieve of 100 mesh to obtain apple juice. 70% sugar solution is used to prepare apple juice with 12% sugar content, and then 0.6g VC and 1g citric acid are required for every 1kg of fruit juice.

[0070] T...

Embodiment 2

[0072] Select fresh apples with complete fruit shape, uniform maturity and size, no pests, no damage, and no rot. Rinse the apples with clean water to remove the sediment and impurities on the surface; use a special manual peeling knife or mechanical peeling to eliminate The thickness of the peel is within 1.2mm. Use a knife to cut in half longitudinally along the suture line. Larger apples can be cut into 4 pieces, and the cut surface should be smooth. Remove the core and handle with a knife, and keep the length of the cut at 15mm. Soak in a mixed aqueous solution of 0.1% VC and 0.1% citric acid for 5 minutes to protect the color.

[0073] Drain the color-protected apple pieces and put them in a press to squeeze the juice. The squeezed slurry was filtered through a centrifugal filter (2800r, 15min) with a screen of 120 mesh to obtain apple juice. 70% sugar solution is used to prepare apple juice with 9% brix, and then 0.5g VC and 1.2g citric acid are required for every 1kg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com