Production method of polypropylene and device thereof

A production device and production method technology, which is applied in the field of polypropylene, can solve problems such as raw materials, steam, and heat energy not being recovered, waste gas, waste water, and waste heat not being treated, and environmental pollution, so as to improve heat energy utilization efficiency and eliminate safety hazards. Hidden dangers and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

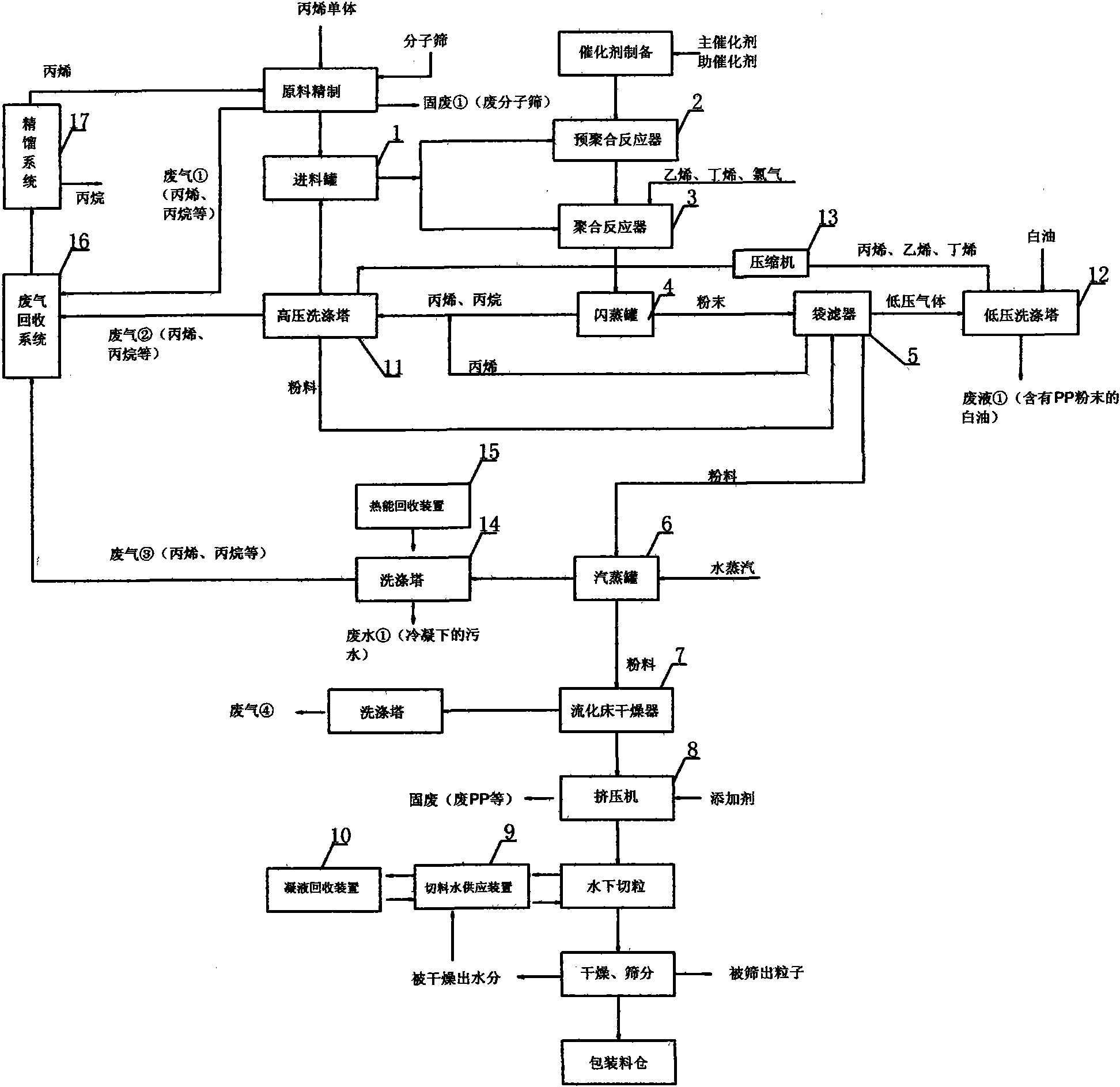

[0043] like figure 1 Shown, the production device of polypropylene of the present invention mainly comprises:

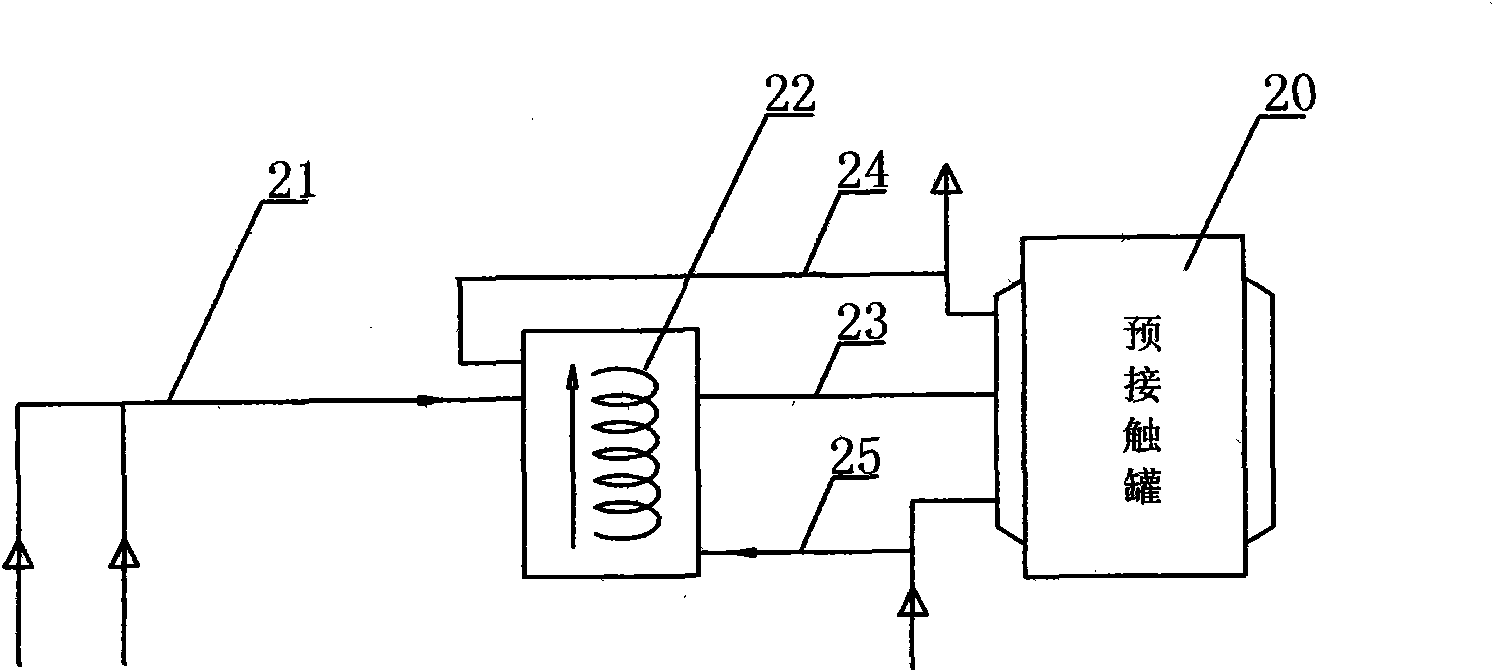

[0044] Polymerization reaction unit, the polymerization reaction unit is connected with feed tank 1, and is used for polymerizing propylene and ethylene monomers to obtain polymer slurry, including pre-contact tank 2, pre-polymerization reactor 3, and polymerization reactor 3 connected in sequence ; An additional heat exchanger is provided at the inlet pipeline of the precontact tank 2;

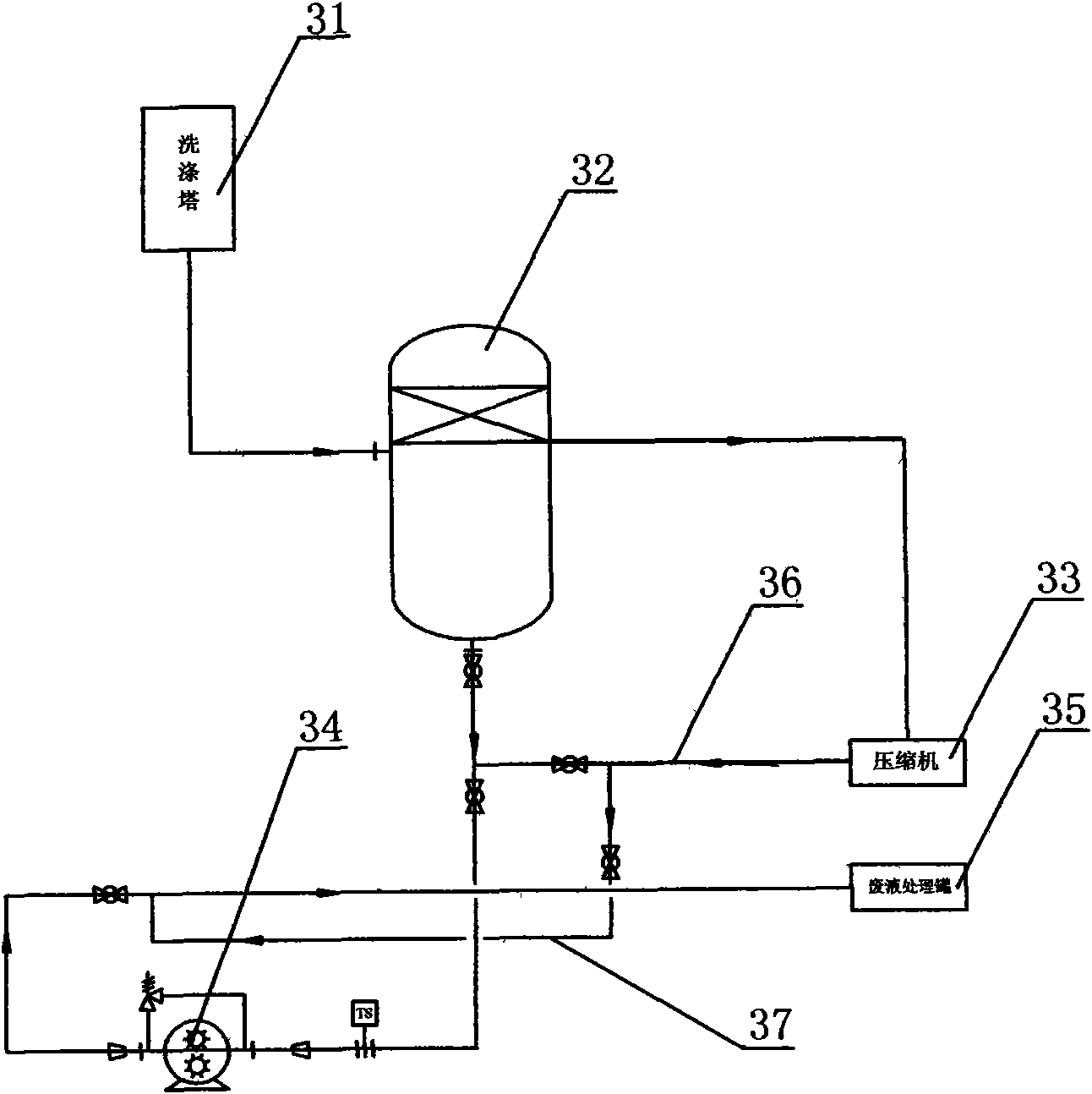

[0045] The flash degassing unit is used to separate the polymer slurry produced by the polymerization reaction unit from the propylene monomer, including a flash tank 4 connected to the polymerization reactor 3, a bag filter 5 connected to the flash tank 4, and high-pressure washing The tower 11 is connected with the flash tank 4 on the one hand, and connected with the feed tank 1 on the other hand, the low-pressure scrubber 12 is connected with the bag filter 5 on the one hand, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com