Method for separating butane and butylenes, and dedicated installation

A technology of butene and butane, which is applied in the field of carbon four-component extraction and rectification separation of butane and butene in oil refineries, a method for separating butane and butene and its special equipment, which can solve the problem of butane and butane Solve the problems of low olefin yield and low purity, and achieve the effect of improving yield and purity, improving purity, and reducing foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is not limited by the following examples, and the specific implementation manner can be determined according to the above-mentioned technical solutions and actual conditions of the present invention. Percentages in the present invention generally refer to percentages by weight.

[0042] Below in conjunction with preferred embodiment the present invention is further discussed:

[0043] The best embodiment uses the carbon four components of the refinery as the raw material, from which high-purity butene products are separated, and high-purity butane products can also be obtained.

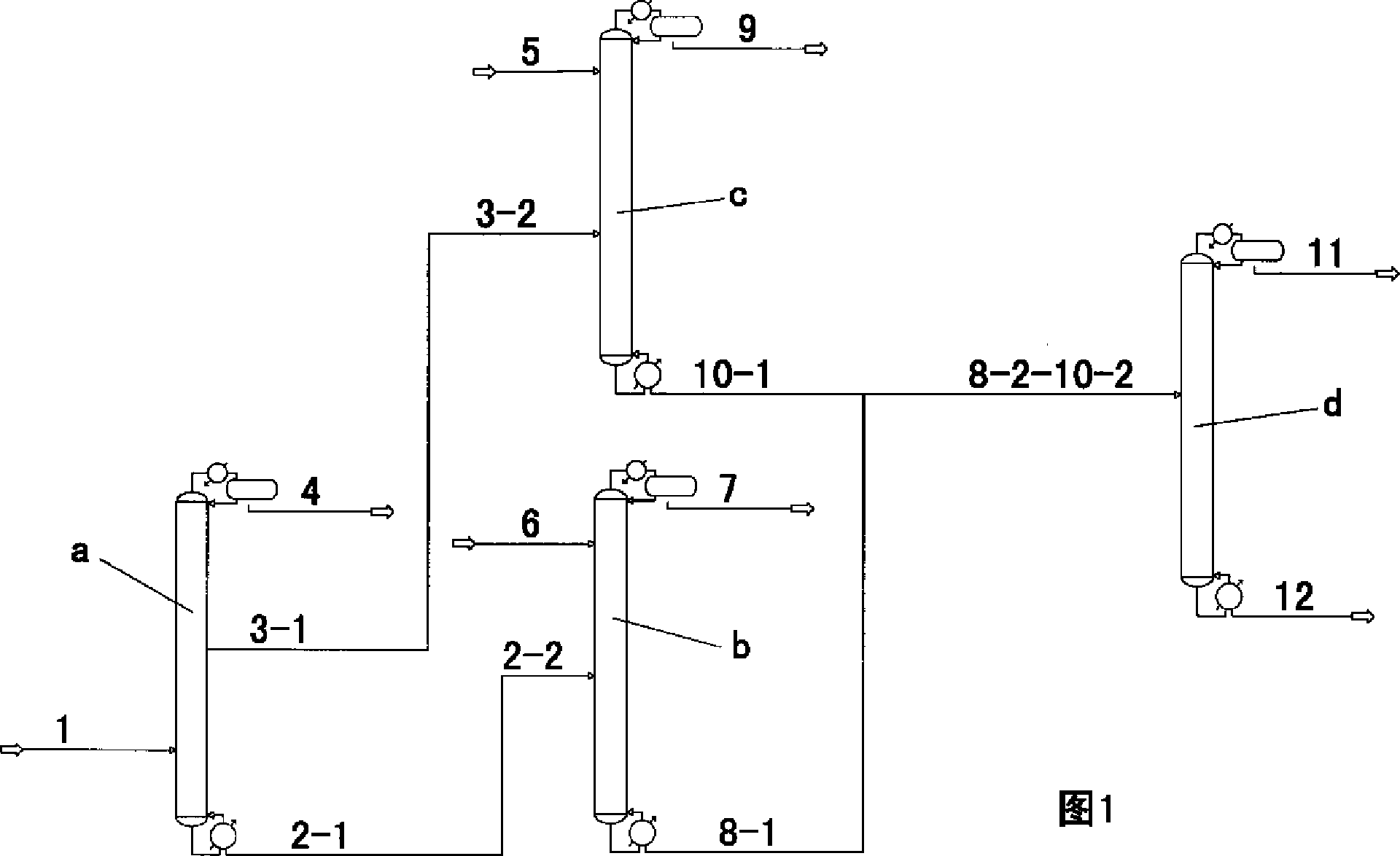

[0044] The specific structure of the special device for separating butane and butene products from the carbon four-component raw material is as follows: As shown in Figure 1, the special device includes a common raw material pretreatment rectification tower a, a heavy component extractive rectification tower b. Light and heavy component extractive distillation tower c and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com