Process method for producing base oil by regenerating waste lubricating oil

A technology for regenerating base oil and waste lubricating oil, which is applied in the direction of lubricating composition, multi-stage series refining process, etc., which can solve the problem of flexible adjustment of production process of waste lubricating oil, inability to deal with highly oxidative deterioration, and emulsification of waste lubricating oil and other issues to achieve the effects of maximizing economic benefits, shortening residence time, good environmental benefits and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

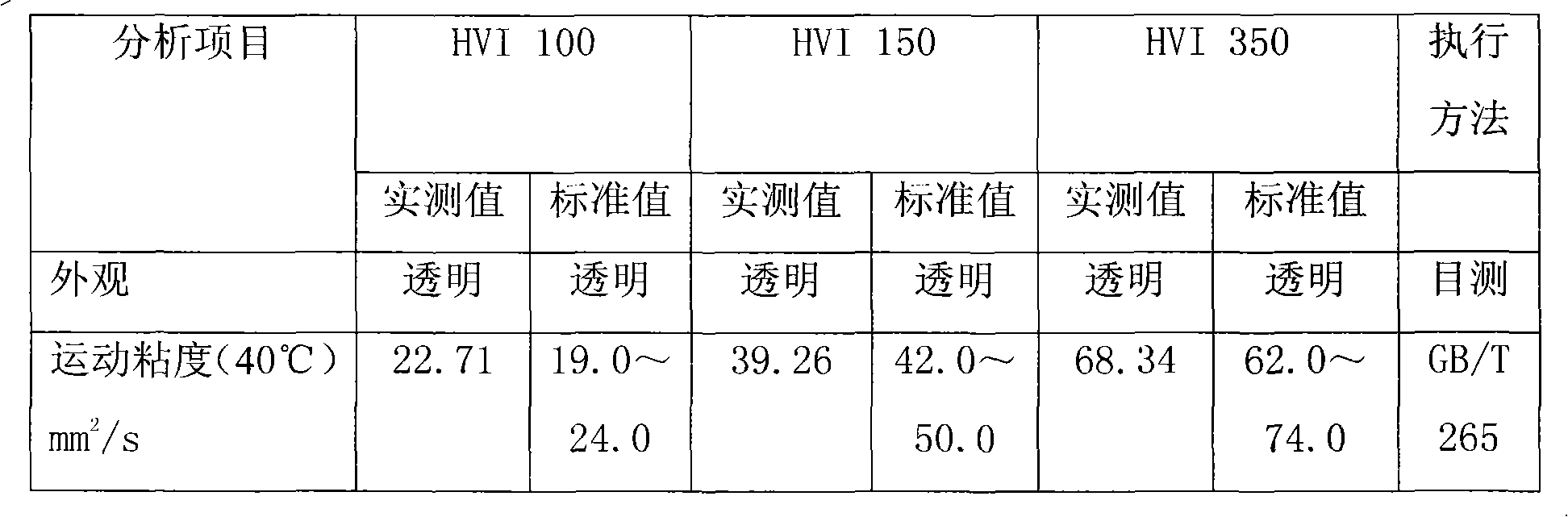

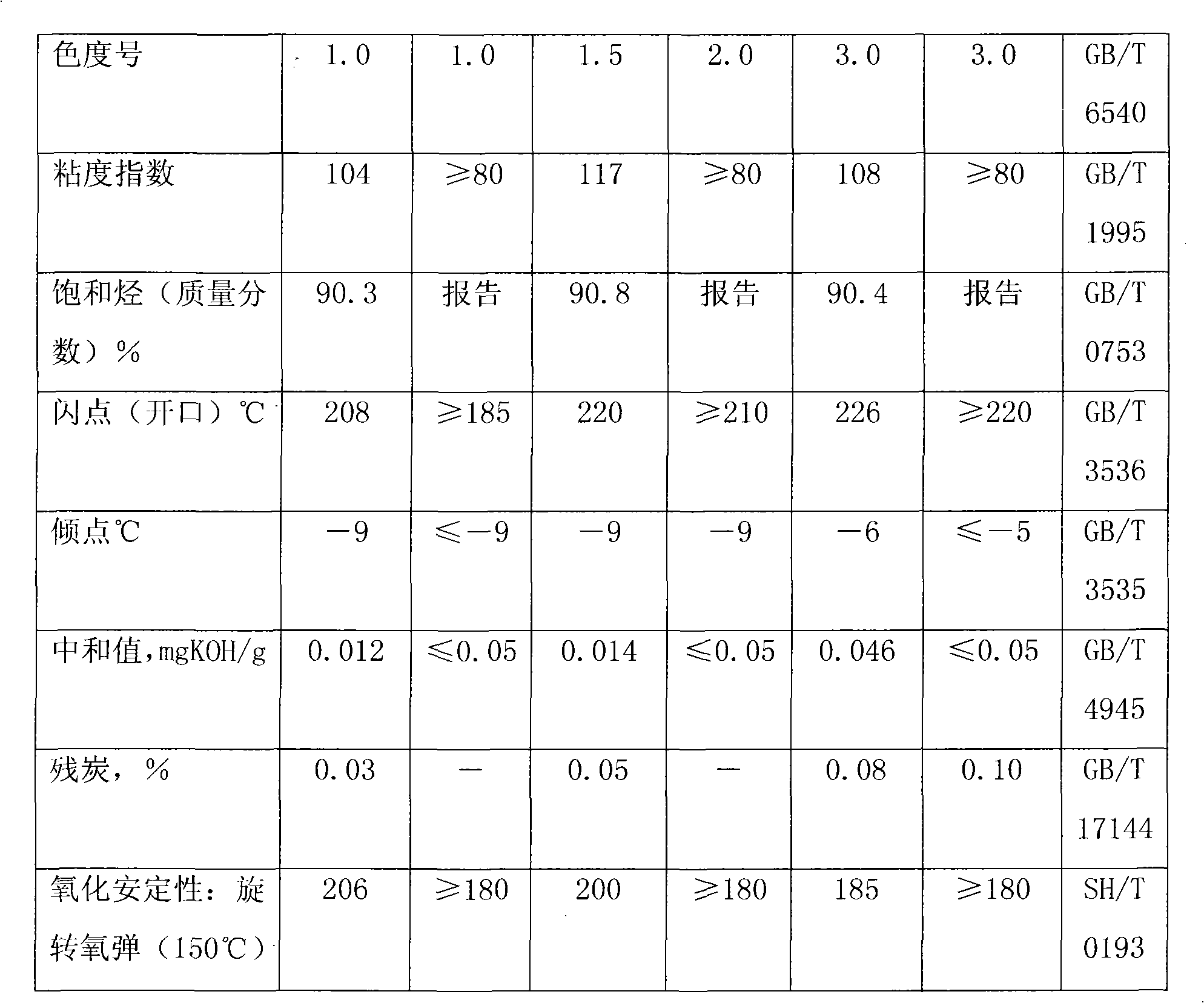

example 1

[0039] A process for regenerating base oil from waste lubricating oil of the present invention is achieved through the process steps of waste lubricating oil pretreatment, thin film evaporation, molecular distillation, clay refining and flash degassing:

[0040] 1) Pretreatment

[0041] Pump 15 tons of waste lubricating oil from the collection tank area into the settling tank of the pretreatment unit, acid value 0.2mgKOH / g waste lubricating oil, add 5% caustic soda 80kg to neutralize to 0.05mg KOH / g waste lubricating oil, stir for 30min , heat up at the same time, keep the waste lubricating oil at 70°C and let it settle for 10 hours to remove moisture and large particle size impurities, and then filter to further remove particle impurities above 5 μm, and then pump it into the raw material tank for Thin film evaporation provides raw materials;

[0042] 2) Thin film evaporation

[0043] The waste lubricating oil in the raw material tank is preheated to 140°C by the heat excha...

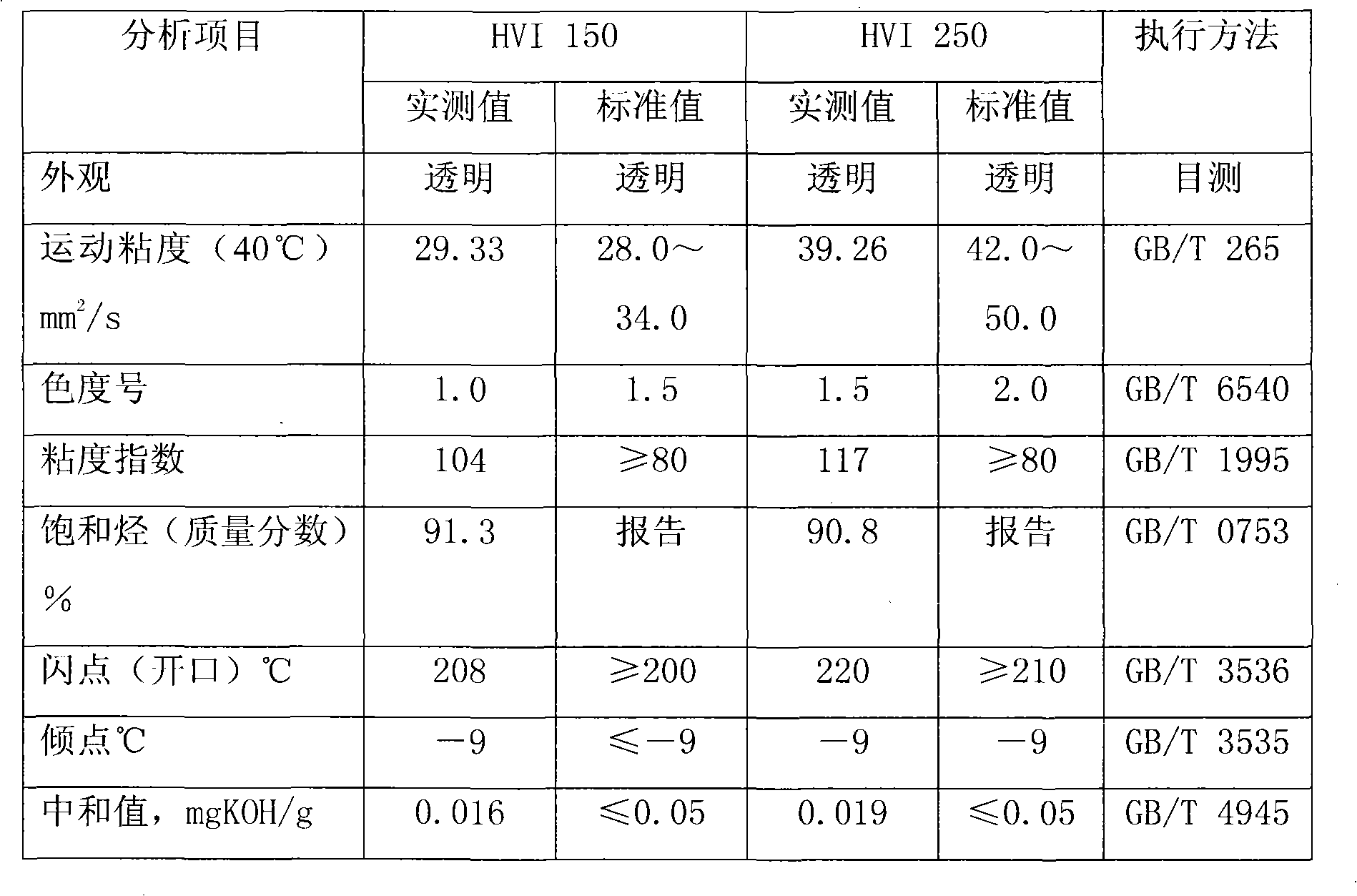

example 2

[0051] A process for regenerating base oil from waste lubricating oil of the present invention is achieved through the process steps of waste lubricating oil pretreatment, thin film evaporation, molecular distillation, clay refining and flash degassing:

[0052] 1) Pretreatment

[0053] Pump 15 tons of waste lubricating oil from the collection tank area into the settling tank of the pretreatment unit, acid value 0.2mgKOH / g waste lubricating oil, add 5% caustic soda 80kg to neutralize to 0.05mg KOH / g waste lubricating oil, stir for 40min , heat up at the same time, keep the waste lubricating oil at 75°C and let it settle for 12 hours to remove moisture and large particle size impurities, and then filter to further remove particle impurities above 5 μm, and then pump it into the raw material tank for Thin film evaporation provides raw materials;

[0054] 2) Thin film evaporation

[0055] The waste lubricating oil in the raw material tank is preheated to 150°C by the heat excha...

example 3

[0063] A process for regenerating base oil from waste lubricating oil of the present invention is achieved through the process steps of waste lubricating oil pretreatment, thin film evaporation, molecular distillation, clay refining and flash degassing:

[0064] 1) Pretreatment

[0065] Pump 15 tons of waste lubricating oil from the collection tank area into the settling tank of the pretreatment unit, acid value 0.2mgKOH / g waste lubricating oil, add 5% caustic soda 80kg to neutralize to 0.05mg KOH / g waste lubricating oil, stir for 40min , heat up at the same time, keep the waste lubricating oil at 80°C and let it settle for 8 hours to remove water and large particle size impurities, and then filter to further remove particle impurities above 5 μm, and then pump it into the raw material tank for Thin film evaporation provides raw materials;

[0066] 2) Thin film evaporation

[0067] The waste lubricating oil in the raw material tank is preheated to 150°C by the heat exchanger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com