Method for preparing titanium sponge

A production method, the technology of sponge titanium, applied in the field of sponge titanium production, can solve the problems of affecting the reaction speed, increasing the cost, affecting the reduction reaction speed, etc., and achieve the effect of improving the utilization rate, increasing the cost, and increasing the first reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

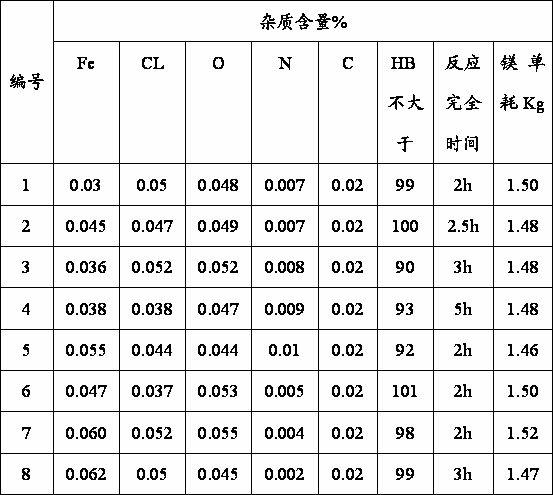

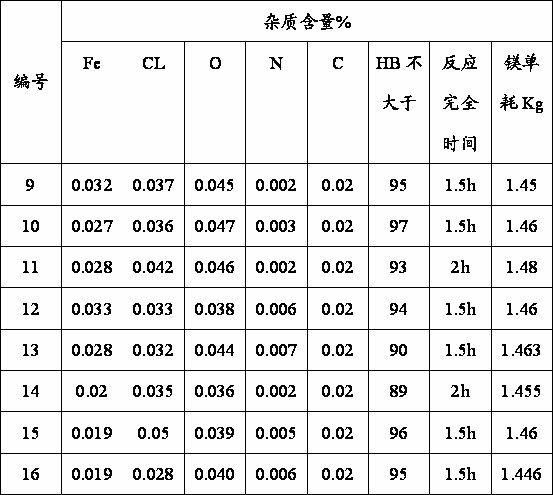

Examples

Embodiment 1

[0025] The invention provides a method for producing titanium sponge, said method comprising the following steps:

[0026] a. 4.2 tons of magnesium metal are installed in the reactor;

[0027] b. Prepare a magnesium chloride block of 1mm to 100mm, and the weight ratio of metal magnesium to magnesium chloride is 4:1;

[0028] c. Add the magnesium chloride block evenly to the top of the metal magnesium in the reactor;

[0029] d. Use a Roots pump to evacuate for 30 minutes, then input argon to a positive pressure of 0.05mPa for protection, and wait for it to enter the furnace;

[0030] e. The temperature change after entering the furnace is: 150°C constant temperature degassing for 2 hours; 200°C constant temperature degassing for 2 hours; 300°C constant temperature degassing for 2 hours; then increase the temperature to 800-880°C and add liquid titanium tetrachloride for reduction reaction;

[0031] f. Add titanium tetrachloride in 10 times: add 1000kg for the first time, 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com