Synthetic method of polyether polyatomic alcohol

A technology of polyether polyol and synthesis method, applied in the field of chemical product manufacturing, can solve the problems of poor compatibility, poor stability, delamination and the like, and achieve the effects of low viscosity, low cost and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

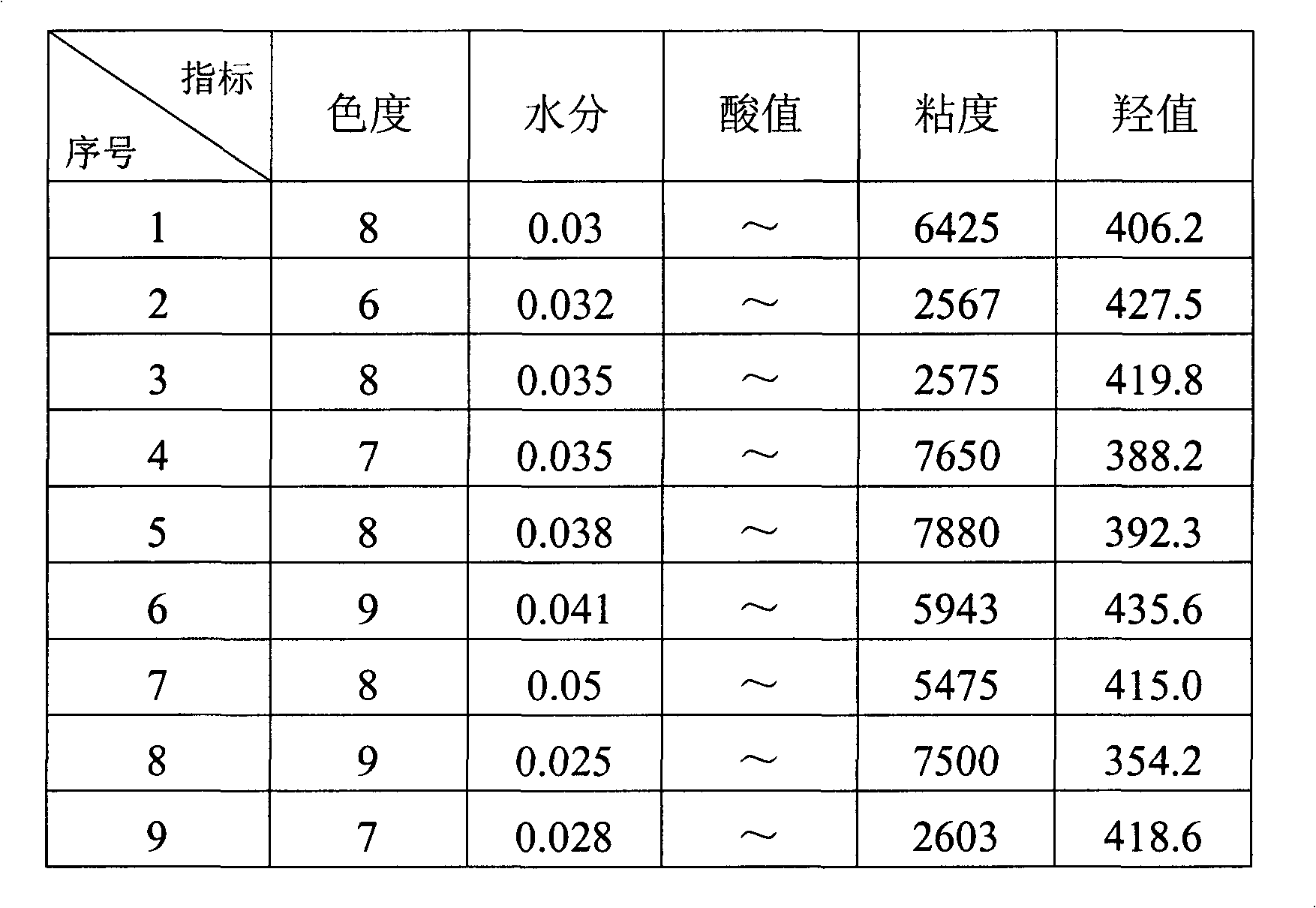

Examples

Embodiment 1

[0017] Example 1: Diethylene glycol 690kg, palm oil 855kg, white granulated sugar 2275kg, potassium hydroxide 35kg, PO5640kg; ring-opening polymerization temperature 105-115°C, polymerization time 5-10 hours; aging temperature 110-115°C, aging time 4 Hours; degassing for 15 minutes after aging, add 20kg of glacial acetic acid, dehydrate until qualified, dehydration temperature 105 ~ 125 ℃.

Embodiment 2

[0018] Example 2: Propylene glycol 720kg, white granulated sugar 1895kg, dimethylamine 140kg, PO 1400kg, ring-opening polymerization and curing first, polymerization temperature 85-95°C, time 2-4 hours; curing temperature 85-100°C, curing time 1 hour; After aging, add 1800kg of soybean oil, dehydrate for half an hour, and the dehydration temperature is 105°C-110°C; after dehydration, continue to add PO2480kg for polymerization reaction and aging, the polymerization temperature is 105-115°C, the time is 5-10 hours, and the aging temperature is 110-115 ℃, aging time 3 hours; degassing 15 minutes, continue dehydration to pass, dehydration temperature 105 ~ 125 ℃.

Embodiment 3

[0019] Example 3: Diethylene glycol 1044kg, cottonseed oil 1340kg, white sugar 1827kg, dimethylamine 44kg, ethylenediamine 35kg, PO4437kg; ring-opening polymerization temperature 105-115°C, polymerization time 5-10 hours; aging temperature 110-115 ℃, the aging time is 4 hours; degassing for 15 minutes, continue dehydration to pass, dehydration temperature 105 ~ 125 ℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com