Gas injection pressure-stabilizing drilling method

A technology for drilling and stabilizing pressure, which is applied in drilling equipment and methods, drilling equipment, earthwork drilling and production, etc. It can solve the problems of being unable to adapt to fluid-containing strata in the narrow "blowout safety pressure window", so as to improve safety and ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

[0054] The blowout preventer combination for underbalanced drilling is equipped at the wellhead, including rotary control head (RCHS) or rotary blowout preventer (RBOP), and the return system is equipped with choke valves for underbalanced drilling, choke manifolds, multiphase separators, Closed circulation system, spray ignition device, etc.

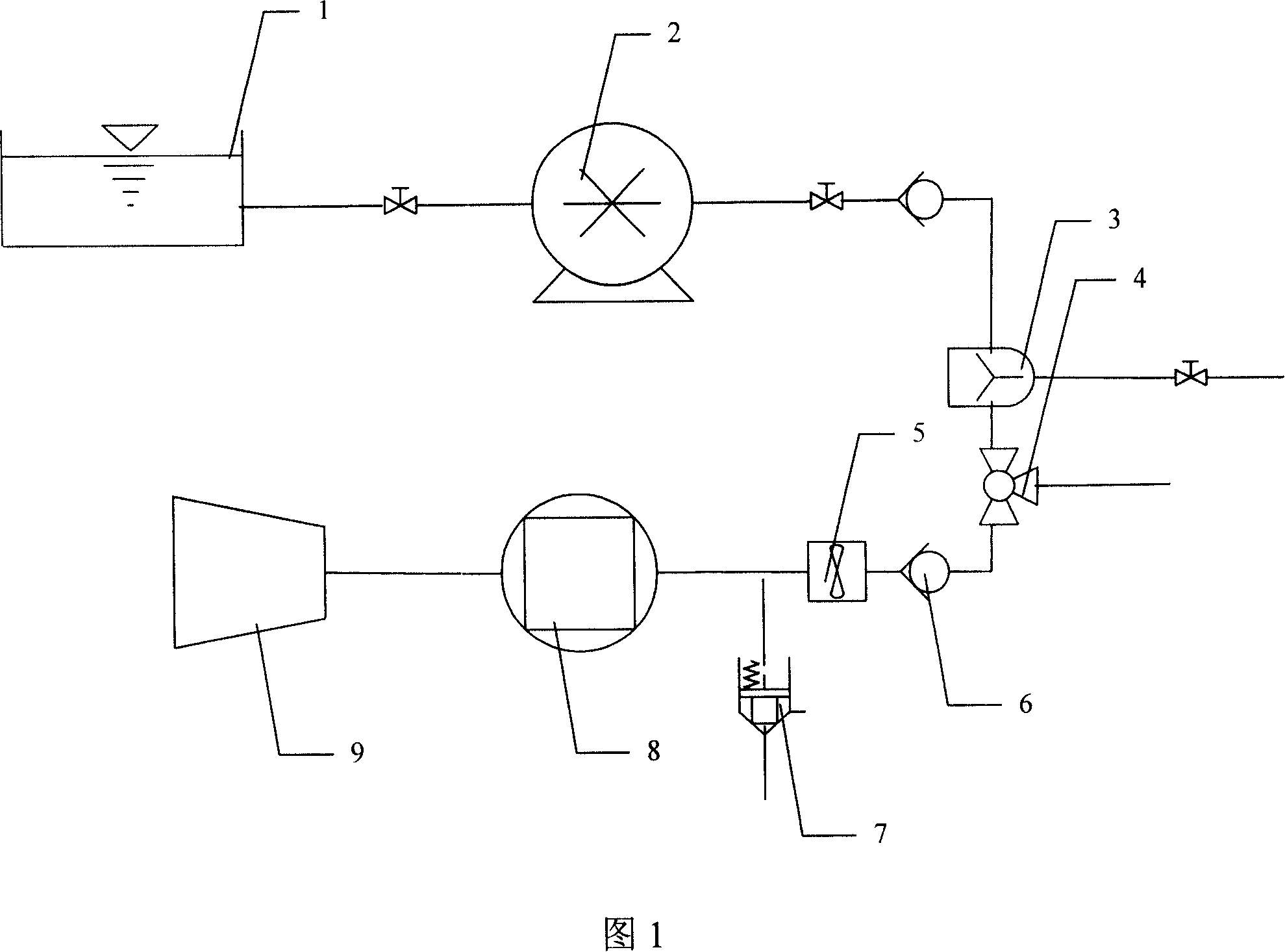

[0055] The wellhead is also equipped with a high-pressure gas injection system, as shown in Figure 1, the high-pressure gas injection system includes a mud tank 1, a mud pump 2 connected to the mud tank 1, a mixer 3 connected to the mud pump 2, and one end of the mixer 3 is connected to The other end is connected to the three-way cock valve 4, the three-way cock valve 4 is connected to the one-way valve 5, the one-way valve 5 is connected to the flow meter 6, and the flow meter 6 is connected to the needle v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com