Method for converting n-alkane into isoalkane by gold-loaded molecular sieve catalyst

A technology of zeolite catalyst and n-butane, which is applied in the field of isoparaffins, and can solve the problems such as inability to obtain catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0118] Preparation of 0.1% Au / HZSM-5:

[0119] (1). Referring to the method disclosed in patent CN100364890C, ZSM-5 zeolite raw powder is synthesized, and the zeolite grain size is less than 50nm. Then calcined at 540° C. for 4 hours to obtain ZSM-5 zeolite.

[0120] (2). Ammonium exchange treatment: the calcined zeolite is subjected to ion exchange treatment with an ammonium salt solution at a suitable temperature. Then, it is washed with deionized water, dried and calcined to obtain hydrogen zeolite. Said ammonium salt is ammonium nitrate, the concentration of ammonium salt solution is 0.6mol / L, the liquid-solid volume ratio of ammonium salt solution and zeolite is 5:1, the exchange temperature is 30°C, the exchange time is 1 hour, and the exchange times are 2 times . The drying temperature is 110°C, the drying time is 12 hours, the firing temperature is 540°C, and the firing time is 6 hours. Na after exchange + The content is not higher than 0.5%.

[0121] (3). Acid p...

Embodiment 2

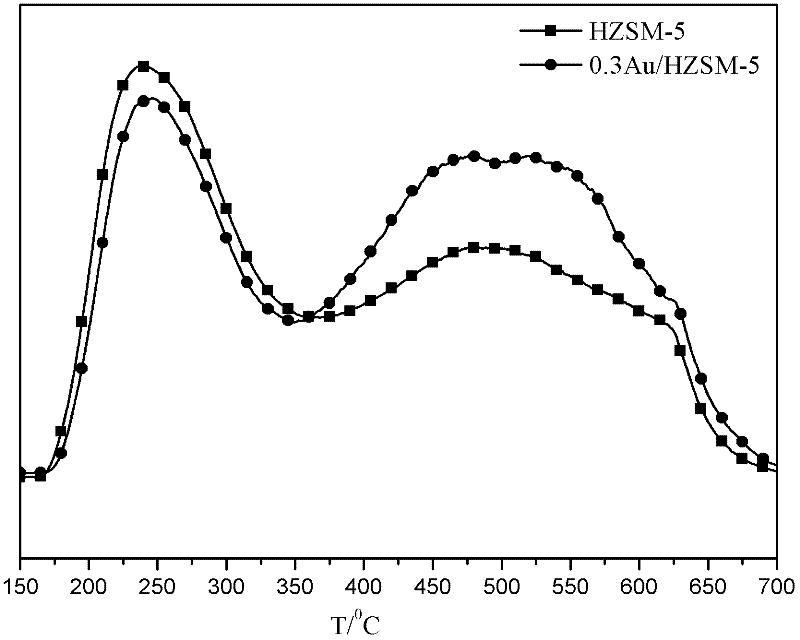

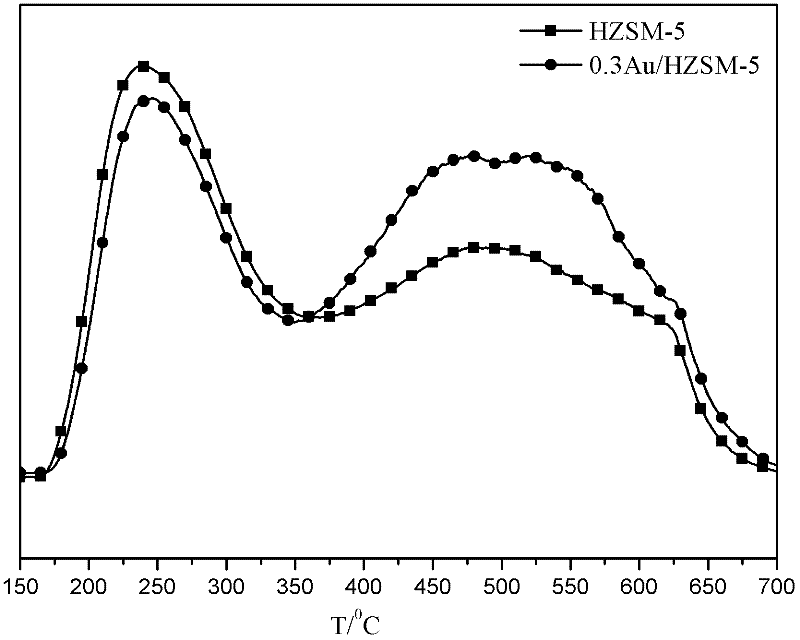

[0126] Repeat Example 1, but change the amount of chloroauric acid solution into 3.14ml and add water to dilute to 10ml, and the roasting temperature is 300°C. A 0.3% Au / HZSM-5 supported gold catalyst was obtained. Labeled: A-2.

Embodiment 3

[0128] Repeat Example 1, but change the vacuum to -0.01MPa, change the amount of chloroauric acid solution to 10.46ml, add water and dilute to 20ml, and obtain 1.0% Au / HZSM-5 supported gold catalyst. Labeled: A-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com