Patents

Literature

34 results about "Carbonium ion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

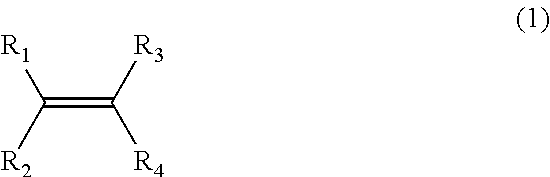

In chemistry, carbonium ion is any cation that has a pentavalent carbon atom, The name carbonium may also be used for the simplest member of the class, properly called methanium (CH⁺₅), where the five valences are filled with hydrogen atoms.

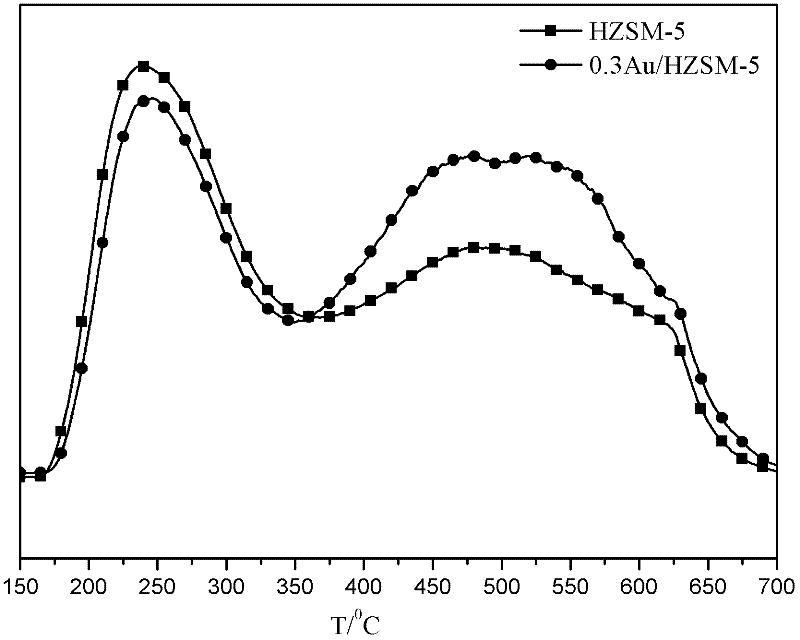

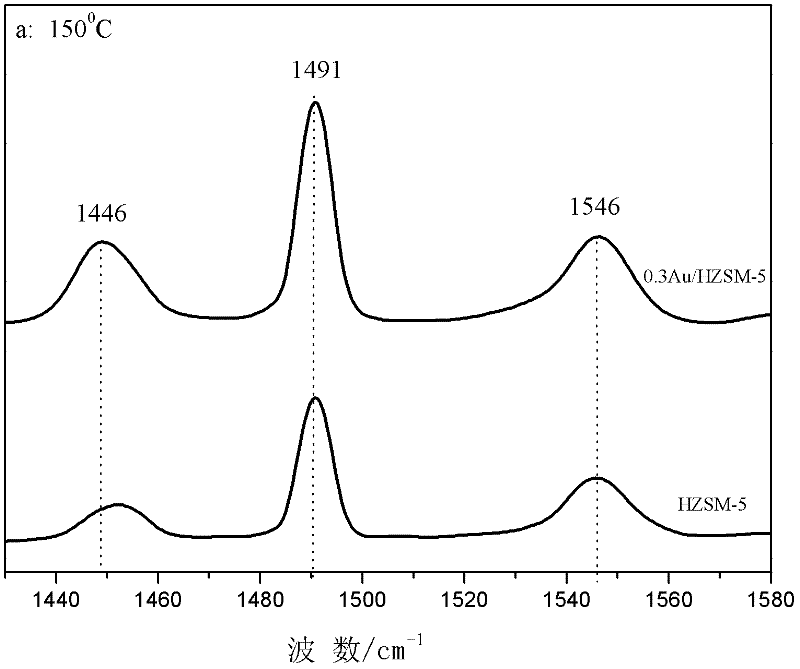

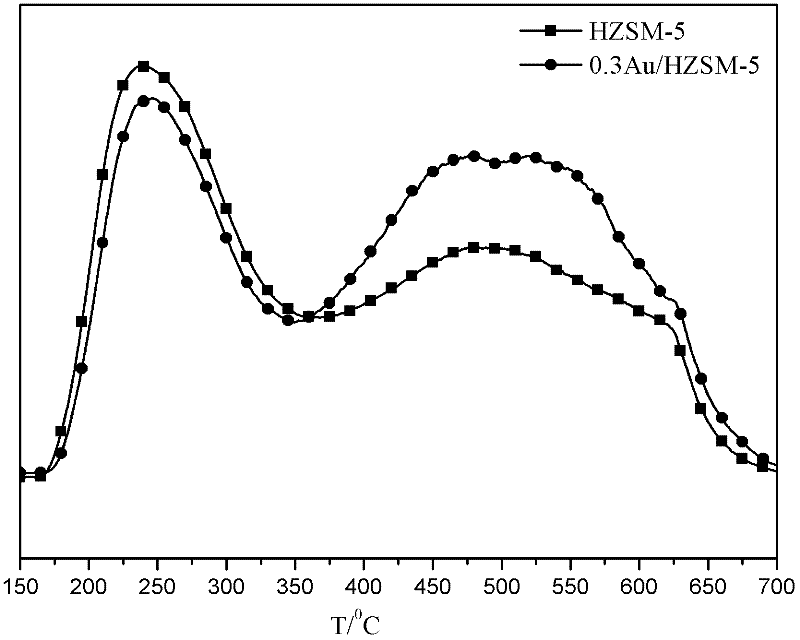

Method for converting n-alkane into isoalkane by gold-loaded molecular sieve catalyst

InactiveCN102416341AEasy to prepareIncrease acidityHydrocarbon by isomerisationMolecular sieve catalystsAlkaneIsomerization

A method for converting n-alkane into isoalkane by a gold-loaded molecular sieve catalyst belongs to the technical field of catalysts. After a molecular sieve is treated by completely negative pressure degasification and purification, a gold precursor is loaded on the molecular sieve carrier by a negative pressure deposition precipitation method so as to form a Si-O(H)-Au structure. The molecular sieve is a high-silica zeolite molecular sieve; the preparation of gold-loaded catalyst under a negative pressure condition by the deposition precipitation method facilitates the purification of the internal and external surfaces and pore channels of the molecular sieve; and Au is easy to enter the pore channels of the molecular sieve to reach high dispersion, and can be combined with silicon hydroxyls on the internal and external surfaces to form the Si-O(H)-Au structure. The method can dehydrogenize n-alkanes to generate alkenes under the difunctional action of metal and the carrier; the alkenes obtain protons at the acid sites to form carbonium ions; and isoalkanes are generated by skeletal isomerization and hydrogenation desorption of the carbonium ions.

Owner:DALIAN UNIV OF TECH

Method for use of modified molecular sieve catalyst in catalytic cracking of propane

InactiveCN103143385AHigh activityLow reaction temperatureMolecular sieve catalystsGaseous fuelsMolecular sieveDeposition precipitation

Belonging to the technical field of catalysts, the invention relates to a method for use of a modified molecular sieve catalyst in catalytic cracking of propane. The method is characterized by subjecting a molecular sieve to a full negative pressure degassing purification treatment, and then loading a gold precursor onto a molecular sieve carrier by a negative pressure deposition-precipitation technique, thus obtaining a uniform and highly disperse granule loaded nanogold catalyst. The molecular sieve refers to a high-silicon zeolite molecular sieve. Preparation of the loaded gold catalyst through the deposition-precipitation technique under a negative pressure condition is in favor of purifying the inner and outer surfaces of the molecular sieve and pore channels, so that Au can be easy to enter the pore channels of the molecular sieve and high dispersion can be achieved. The method provided in the invention can make propane undergo dehydrogenation to produce olefin under the difunctional actions of the metal and the carrier. The olefin can acquire protons at an acid site to form carbonium ions, which then undergo polymerization cracking to generate corresponding olefin.

Owner:DALIAN UNIV OF TECH

Method of using modified molecular sieve catalyst in isobutane catalytic cracking

InactiveCN103130604AEasy to prepareGood dispersionMolecular sieve catalystsBulk chemical productionMolecular sieveDeposition precipitation

The invention discloses a method of using modified molecular sieve catalyst in isobutane catalytic cracking and belongs to the technical field of catalysts. The method includes the following steps: conducting full negative pressure degassing purification treatment on a molecular sieve, adopting a negative pressure deposition-precipitation method to load a gold precursor to a molecular sieve carrier, and obtaining an even and high-dispersion small particular supported gold catalyst. The molecular sieve is a high-silica zeolite molecular sieve, the supported gold catalyst obtained by the deposition-precipitation method under the condition of negative pressure is beneficial for purifying the inner surface, the outer surface and a duct of the molecular sieve, and Au can easily enter the duct of the molecular sieve to achieve high dissipation. By means of the method, dehydrogenation is conducted on isobutane to produce olefin under double functions of metal and a carrier, the olefin obtains a proton at an acid center to form a carbonium ion, and the carbonium ion conducts polymer lysis to generate a corresponding olefin.

Owner:DALIAN UNIV OF TECH

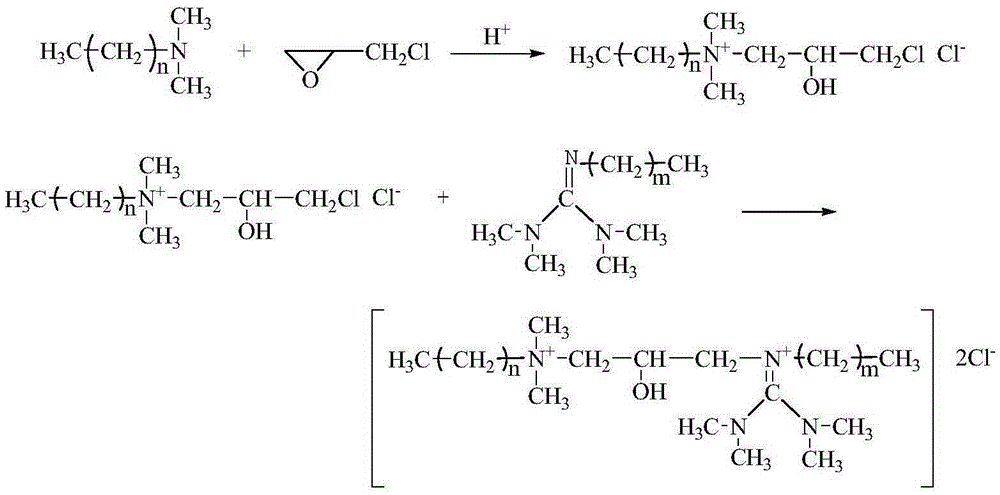

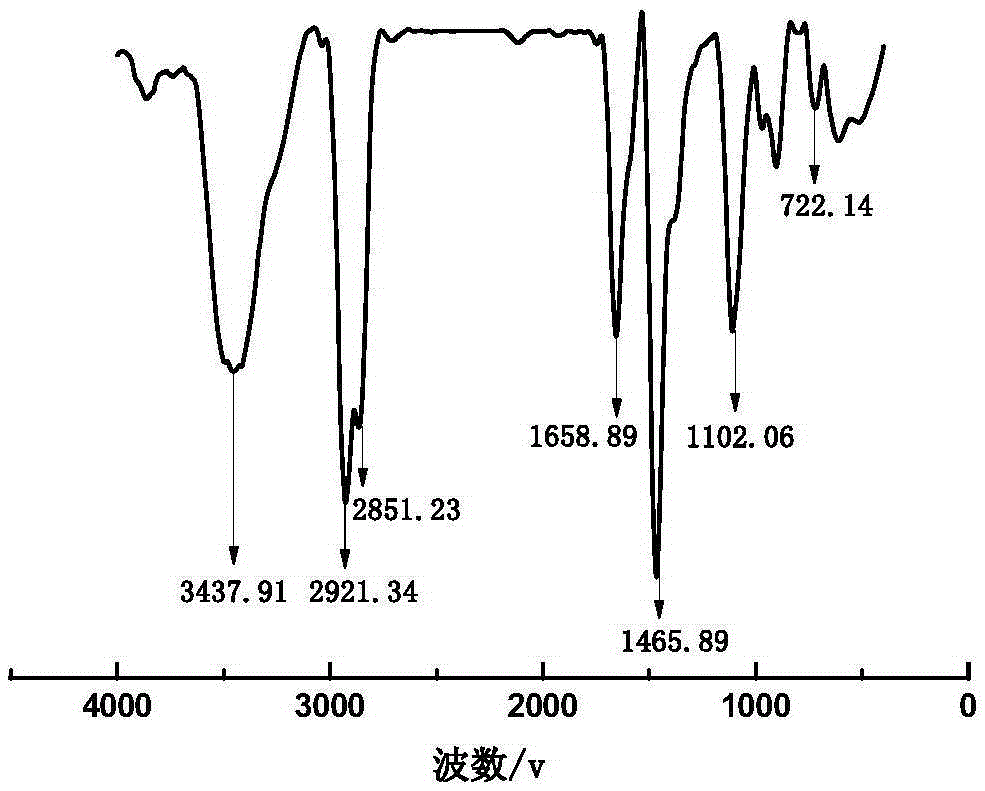

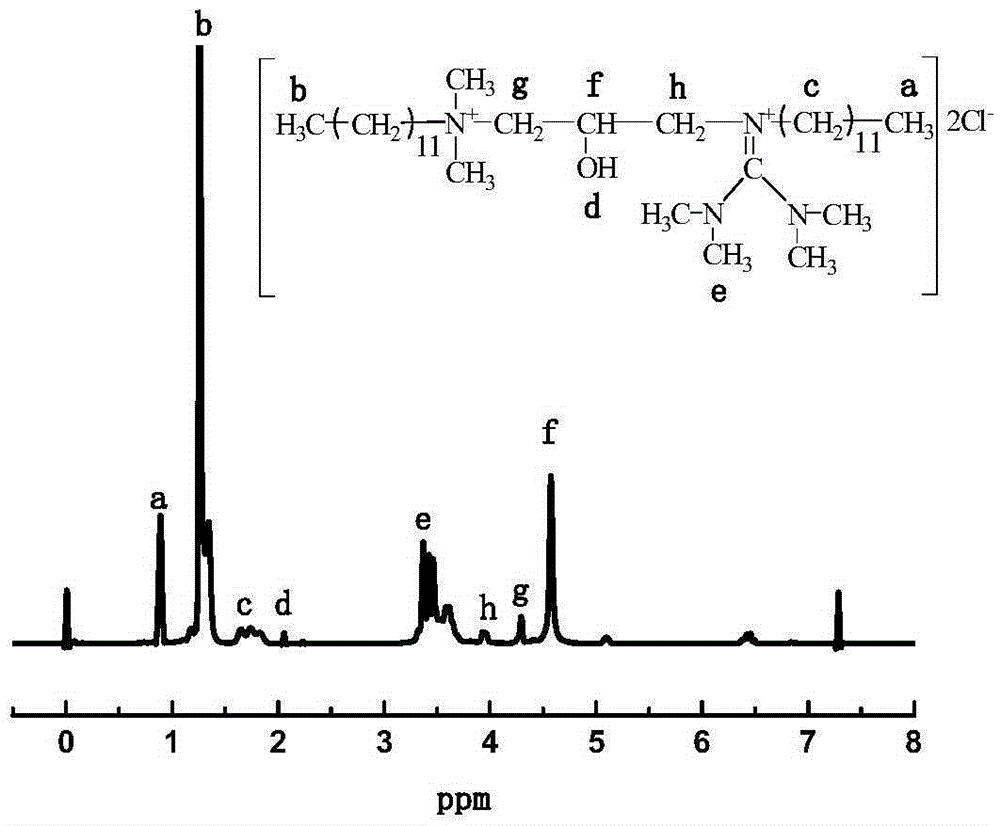

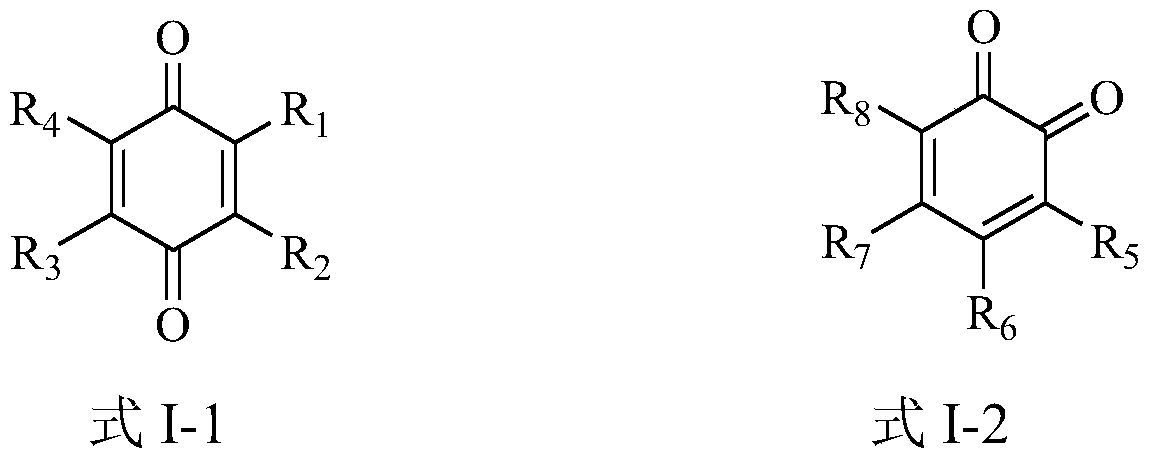

Guanidyl long chain gemini quaternary ammonium salt and preparation method thereof

ActiveCN105294506AImprove shortcomingsImprove surface activityAntibacterial agentsOrganic chemistryQuaternary ammonium cationSurface-active agents

The invention discloses a guanidyl long chain gemini quaternary ammonium salt and a preparation method thereof, wherein long chain gemini quaternary ammonium salts and long chain alkyl tertiary amines are added into a solvent, are added with epichlorohydrin drop by drop in 40-90 DEG C, and obtain intermediate products by reacting after being added drop by drop; and the intermediate products are added into alcohol, are added with long chain guanidine drop by drop in 30-110 DEG C after being uniformly stirred, and react for 4-48h after being added drop by drop to obtain guanidyl long chain gemini quaternary ammonium salts. The guanidyl long chain gemini quaternary ammonium salt and the preparation method thereof adopt open loops of epoxide and bimolecular nucleophilic reactions, wherein H+ and epoxy groups are easy to combine in an open ring reaction of the epoxide, and enable tertiary amines which are used as nucleophilic reagents to be more rapid when attacking carbonium ions. Quaternary ammonium surfactants are in a system in a second reaction, are used as a surface active agent to greatly promote quaternization, and improve reaction speed as a whole. The guanidyl long chain gemini quaternary ammonium salt and the preparation method thereof are simple in reaction process, clear in target products, less in accessory substances and concise in purification process, and further reduces cost.

Owner:SHAANXI UNIV OF SCI & TECH

Method for converting n-paraffins into isoparaffins through using gold supported molecular sieve catalyst

InactiveCN103143386AEasy to prepareSmall gold particlesHydrocarbon by isomerisationMolecular sieve catalystsDeposition precipitationAlkane

A method for converting n-paraffins into isoparaffins through using a gold supported molecular sieve catalyst belongs to the technical field of catalysts. A molecular sieve is subjected to full negative-pressure degassing purifying treatment, and a gold precursor is loaded on the molecular sieve carrier through adopting a negative-pressure deposition-precipitation method to obtain the uniform-dispersion small-granule supported nano-gold catalyst. The molecular sieve is a high-silicon zeolite molecular sieve, and the preparation of the gold supported catalyst through the deposition-precipitation method under a negative pressure is in favor of cleaning the internal and external surfaces and the tunnels of the molecular sieve, so Au can easily enter the tunnels of the molecular sieve to reach high dispersion. The method provided by the invention allows n-paraffins to be dehydrogenated under the metal and carrier difunctional action to generate olefins, olefins obtain protons from acid sites to form carbonium ions, and the carbonium ions undergo skeletal isomerization and hydrogenation desorption to generate isoparaffins.

Owner:DALIAN UNIV OF TECH

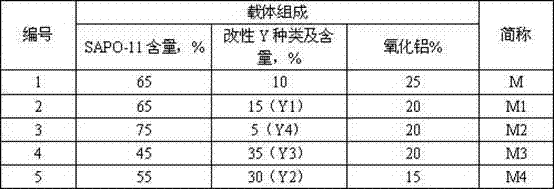

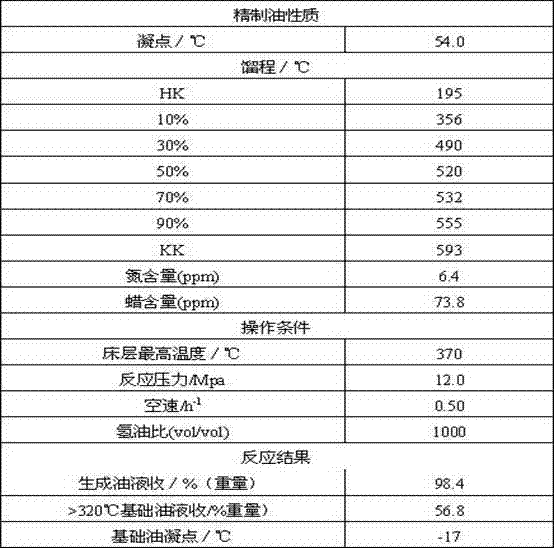

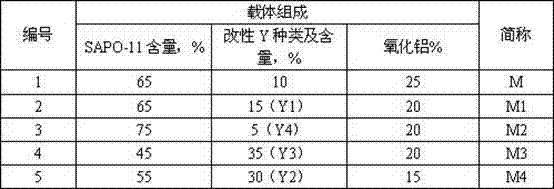

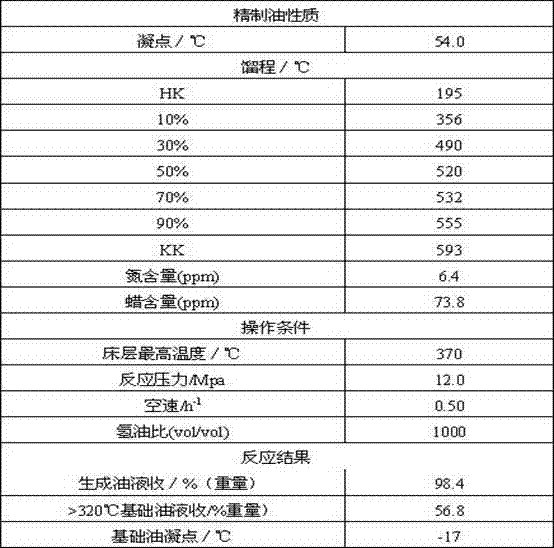

N-butane hydroisomerization catalyst, and preparation method and application thereof

ActiveCN102500413AReduce cloggingChange the pore structureMolecular sieve catalystsHydrocarbon oils refiningAlkaneIsomerization

The invention discloses an n-butane hydroisomerization catalyst, and a preparation method and application thereof. The catalyst is prepared from 5-35 wt% of modified Y molecular sieve, 45-75 wt% of SAPO-11 molecular sieve, 0.05-5.0 wt% of noble metal active component, 0.05-5.0 wt% of assistant active metal component tin and 10-20 wt% of aluminum oxide adhesive, wherein the noble metal active component is dispersed in the modified Y molecular sieve and SAPO-11 molecular sieve. Since the modified Y molecular sieve is added, alkane molecules can generate carbonium ions required by the reaction process more easily; the modified Y molecular sieve has large pore canals, and thus, can effectively decrease the blocked pore canals in the molecular sieve and change the pore canal structure of the catalyst support; and the pore size of the Y molecular sieve can be modified and adjusted to change the pore volume of the molecular sieve and improve the diffusion restriction of the pore canals on the reactant or product molecules, thereby effectively performing the isomerization reaction and obtaining the high-yield isomerizate.

Owner:LUOYANG RONGHUI CHEM TECH CO LTD

Method for production of adamantanol

ActiveCN101891570AShorten the timeHigh yieldPreparation by oxidation reactionsHydroxy group formation/introductionResistPhotoresist

The invention provides a method for production of adamantanol. The adamantane reacts in a mixing solution containing a fuming sulfuric acid and an organic nitrile compound and the obtained reaction solution is hydrolyzed. The adamantanol is industrially beneficially produced by the adamantane at high yield in short time without using a large amount of fuming sulfuric acid and dear carbonium ion generation compound. The adamantanol is used as the raw material of a medicine intermediate and a monomer for a photoresist, the raw material of a photochromic compound and the raw material of a coating, a cement, a binder, a film and an adsorbing material.

Owner:OSAKA ORGANIC CHEM INDS

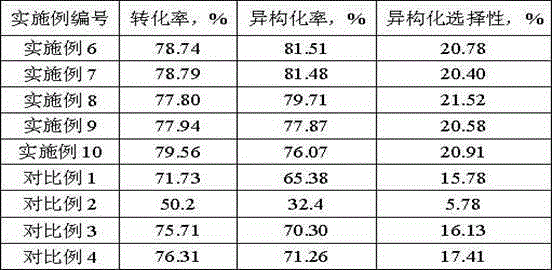

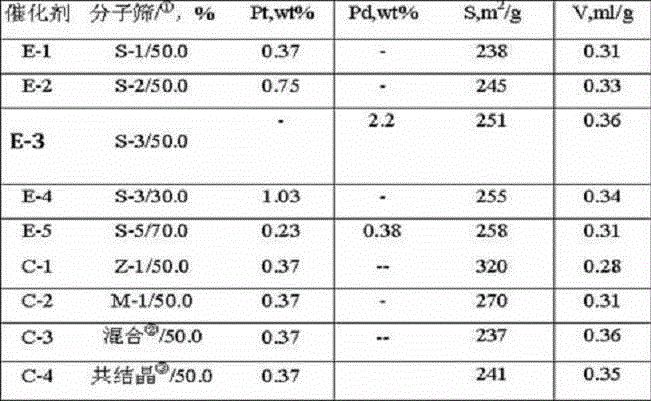

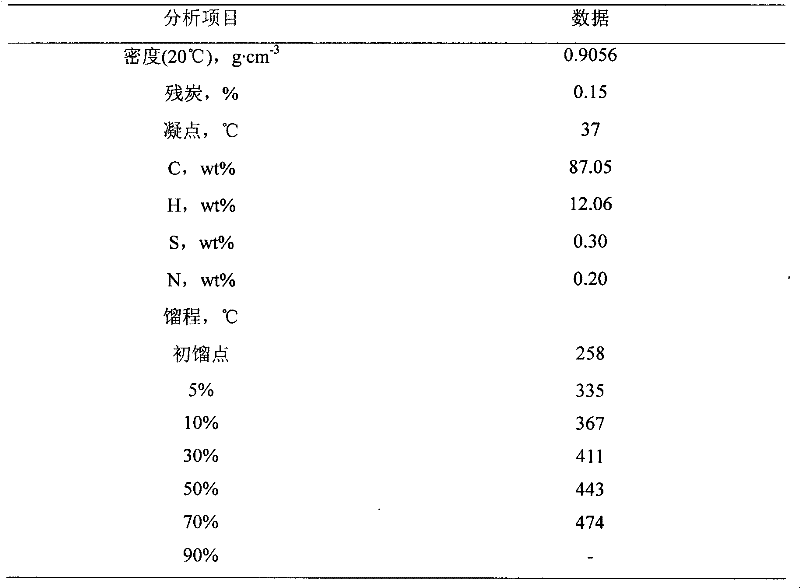

Low-carbon alkane isomerization catalyst and preparation method thereof

InactiveCN106669805AHigh activityHigh selectivityMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveIsomerization

The invention discloses a low-carbon alkane isomerization catalyst and a preparation method thereof. The catalyst contains an MCM-22 / ZSM-35 composite molecular sieve and group-VIII precious metal active components, wherein counted by the weight content of the catalyst, the content of the MCM-22 / ZSM-35 composite molecular sieve is 1.0 to 90 percent, the content of group-VIII precious metals is 0.1 to 1.5 percent, an MCM-22 molecular sieve of the MCM-22 / ZSM-35 composite molecular sieve wraps a ZSM-35 molecular sieve, and the weight content of the MCM-22 in the MCM-22 / ZSM-35 composite molecular sieve is 1.0 to 50 percent. The catalyst can shorten the dwell time of a carbonium ion intermediate in pores of the catalyst, improves the activity and isomerization selectivity and stability of the catalyst, and also suppresses secondary reaction such as polymerization coking and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

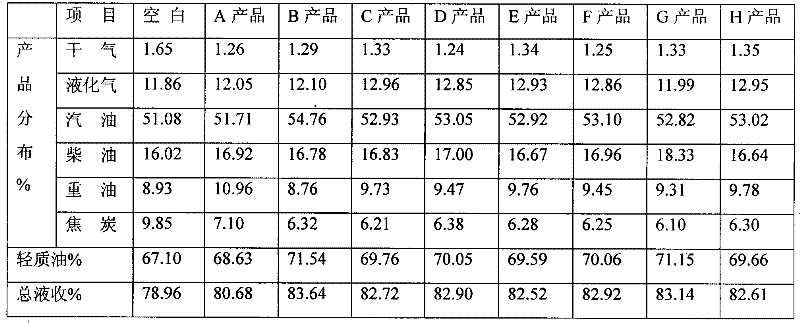

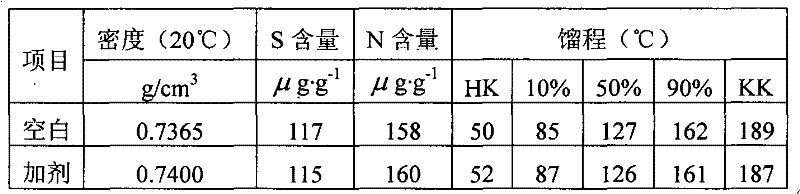

Auxiliary capable of increasing clean oil yield and used for catalytic cracking

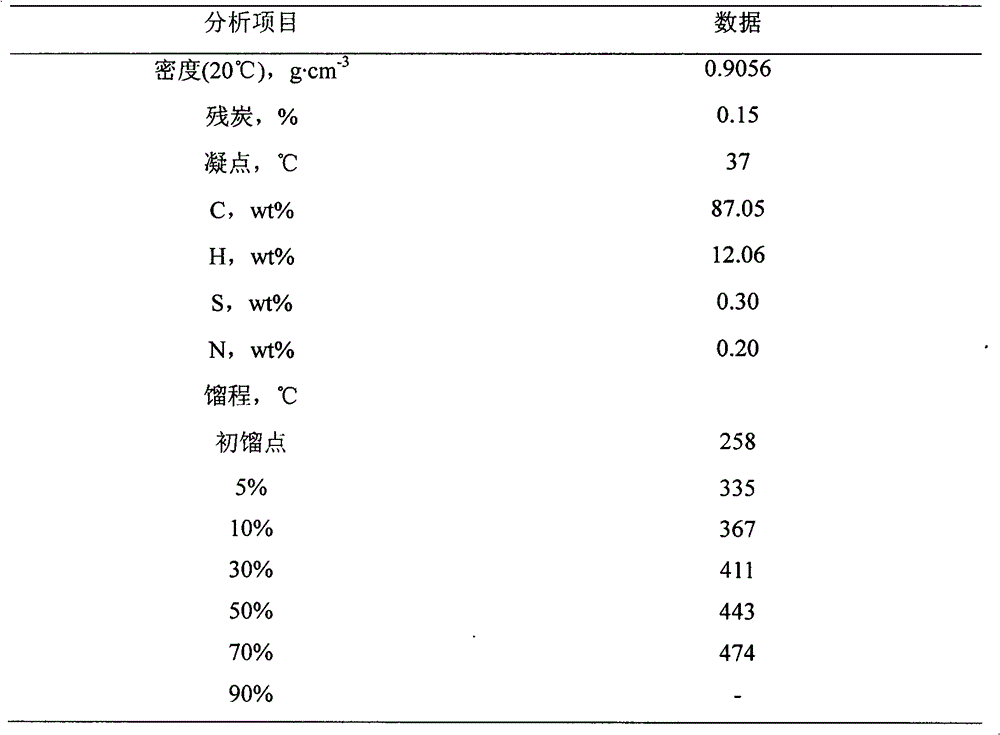

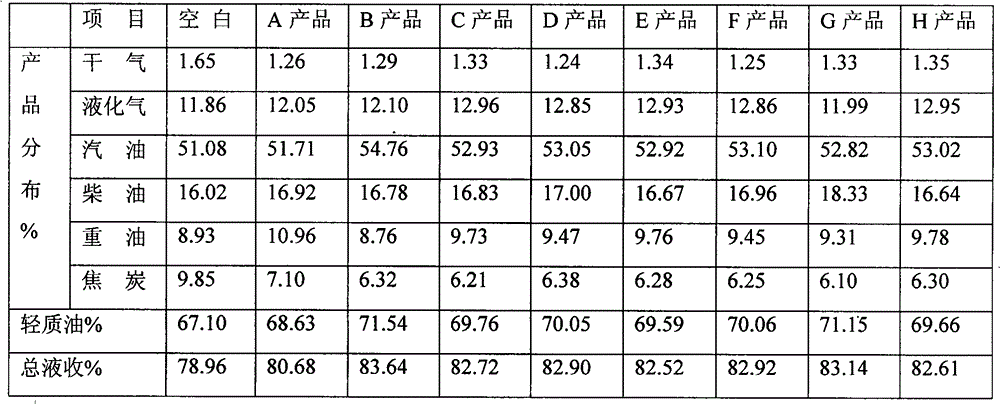

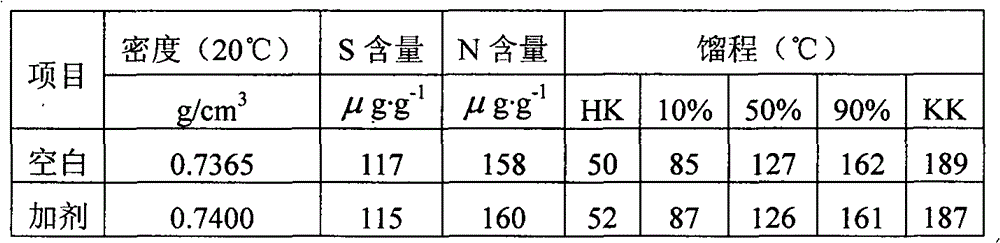

The invention relates to an auxiliary capable of increasing clean oil yield and used for catalytic cracking, which is composed of the following components by weight percentage: 5-15% of dispersing agents, 10-25% of antioxidant, 5-15% of metal ion deactivation agents, 20-35% of mixed rare earth and the balance solvents. By adding the auxiliary in a catalytic cracking system, carbonium ion reaction can be promoted, generation of side reactions such as thermal cracking reaction and dehydrogenation condensation reaction can be restrained, generation of by-products such as dry gas and hard coke is reduced, and yield of products with high additional value such as liquefied gas, gasoline and diesel oil is improved. The auxiliary has the function of a metal passivator and can replace the metal passivator. The auxiliary can effectively passivate metallic nickel and vanadium metal, reduces dehydrogenation activity of the metallic nickel and vanadium metal, accordingly reduces depositing of scaling materials on surfaces of a catalyst, prolongs service life of the catalyst, enables devices to operate for a long time, and is a multifunctional oil soluble liquid auxiliary for catalytic cracking.

Owner:天津市瑞德赛恩新材料开发有限公司

Styrene-isomonoolefin-styrene triblock copolymer and preparation method thereof

The invention relates to a styrene-isomonoolefin-styrene triblock copolymer and a preparation method thereof. The method comprises the following steps: (1) in the presence of an organic solvent and titanium tetrachloride, carrying out first cationic polymerization reaction on isomonoolefin to obtain a polymeric system containing polyisomonoolefin with reaction activities at the tail end; and (2) contacting the polymeric system with a styrene-containing solution, and carrying out second cationic polymerization reaction, wherein the first cationic polymerization reaction in the step (1) also comprises the step of introducing an initiator system, and the initiator system contains at least one compound capable of providing carbonium ions and at least one activator. The method can effectively lower the generation of the styrene homopolymer and styrene bi or high copolymer, thereby effectively enhancing the block polymerization efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for converting n-butane into isobutane through using gold supported molecular sieve catalyst

InactiveCN103145517AEasy to prepareIncrease acidityHydrocarbon by isomerisationMolecular sieve catalystsIsomerizationDesorption

A method for converting n-butane into isobutane through using a gold supported molecular sieve catalyst belongs to the technical field of catalysts. High-dispersion nano-gold particles are formed through the strong reaction of gold and high-silicon zeolite when nano-gold is loaded on the high-silicon zeolite. An acid is formed during the reaction of Au and a carrier because of the polarization effect of Au. A metal-acid difunctional catalyst is formed because the supported gold is still metallic. The molecular sieve is the high-silicon zeolite molecular sieve, and the preparation of the gold supported catalyst through a deposition-precipitation method under a negative pressure is in favor of cleaning the internal and external surfaces and the tunnels of the molecular sieve, so Au can easily enter the tunnels of the molecular sieve to reach high dispersion. The supported gold catalyst prepared in the invention has an acid site and a metal active site which are required by the isomerization of n-butane, so n-butane is dehydrogenated under the metal and acid difunctional action to generate olefin, olefin obtains a proton from the acid site to form a carbonium ion, and the carbonium ion undergoes skeletal isomerization and hydrogenation desorption to generate isobutene.

Owner:DALIAN UNIV OF TECH

Isomerization catalyst and preparation thereof

InactiveCN1255513CReduce concentrationReduce carbon depositionHydrocarbon oils refiningIsomerizationStrong acids

A catalyst for hydroisomerization of n-alkanes with nanometer HBeta zeolite as a carrier. The nanometer HBeta grain size is 30.0nm-180.0nm. The catalyst of the invention can shorten the residence time of the carbenium ion intermediate in the pore channels of the catalyst, improve the selectivity of isomerization products, and simultaneously suppress secondary reactions such as polymerization and coking. The catalyst of the present invention adopts the preparation method of hydrothermal treatment after the metal is loaded first, which reduces the number of stronger L acid centers on the metal oxide-loaded zeolite catalyst, suppresses side reactions such as hydrogen transfer reactions dominated by stronger L acids, and reduces The amount of carbon deposited on the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Auxiliary capable of increasing clean oil yield and used for catalytic cracking

The invention relates to an auxiliary capable of increasing clean oil yield and used for catalytic cracking, which is composed of the following components by weight percentage: 5-15% of dispersing agents, 10-25% of antioxidant, 5-15% of metal ion deactivation agents, 20-35% of mixed rare earth and the balance solvents. By adding the auxiliary in a catalytic cracking system, carbonium ion reaction can be promoted, generation of side reactions such as thermal cracking reaction and dehydrogenation condensation reaction can be restrained, generation of by-products such as dry gas and hard coke is reduced, and yield of products with high additional value such as liquefied gas, gasoline and diesel oil is improved. The auxiliary has the function of a metal passivator and can replace the metal passivator. The auxiliary can effectively passivate metallic nickel and vanadium metal, reduces dehydrogenation activity of the metallic nickel and vanadium metal, accordingly reduces depositing of scaling materials on surfaces of a catalyst, prolongs service life of the catalyst, enables devices to operate for a long time, and is a multifunctional oil soluble liquid auxiliary for catalytic cracking.

Owner:天津市瑞德赛恩新材料开发有限公司

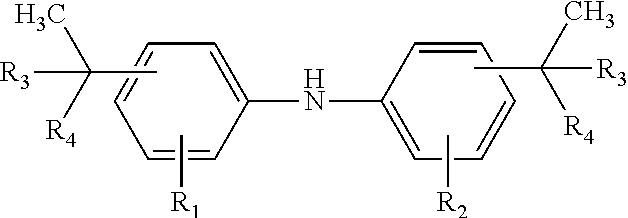

Diaryl amine antioxidants prepared from branched olefins

ActiveUS10487043B2Advantage in handlingHandling compatibilityAmino preparation from aminesAdditivesAlcoholAntioxidant

Diaryl amines are selectively alkylated by reaction with branched olefins, which olefins are capable of forming tertiary carbonium ions and can be conveniently prepared from readily available branched alcohols. The diaryl amine products are effective antioxidants and often comprise a high amount of di-alkylated diaryl amines and a low amount of tri- and tetra-alkylated diaryl amines.

Owner:LENKSESS CORP

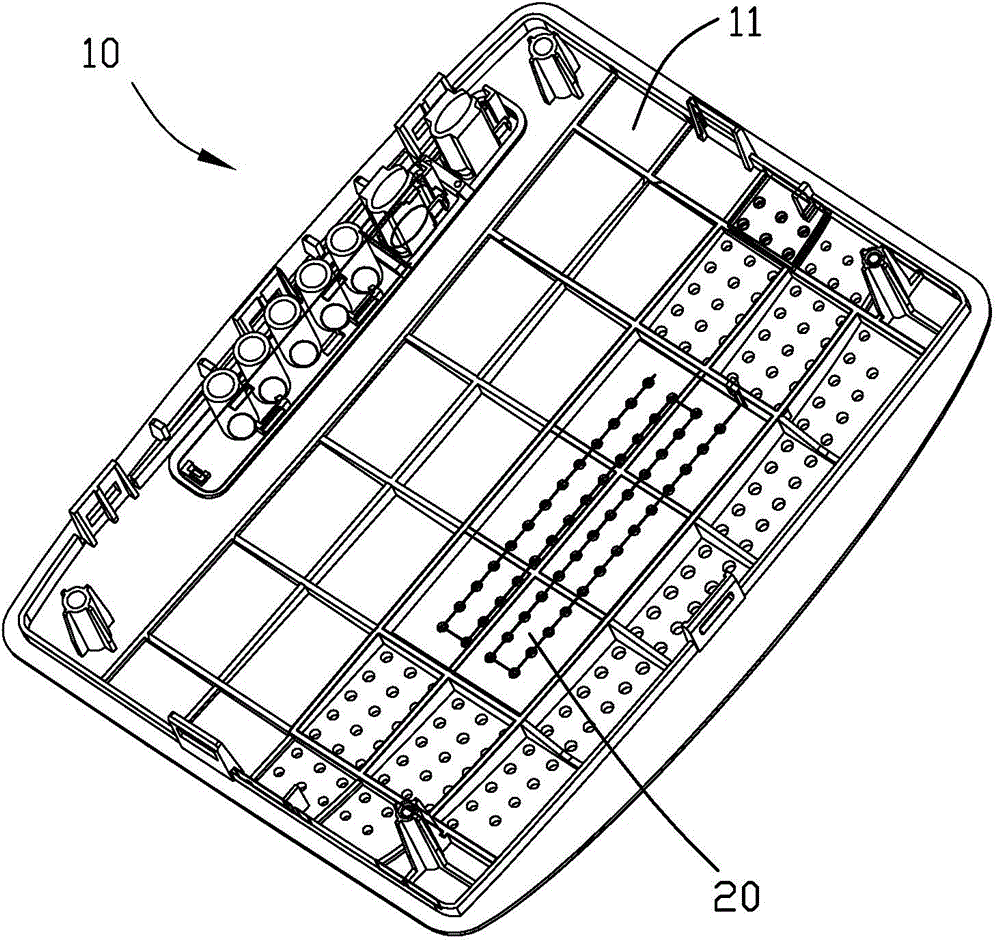

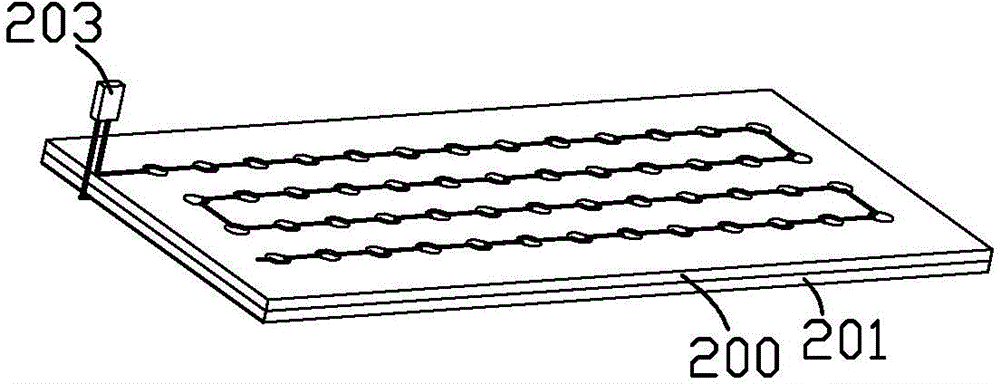

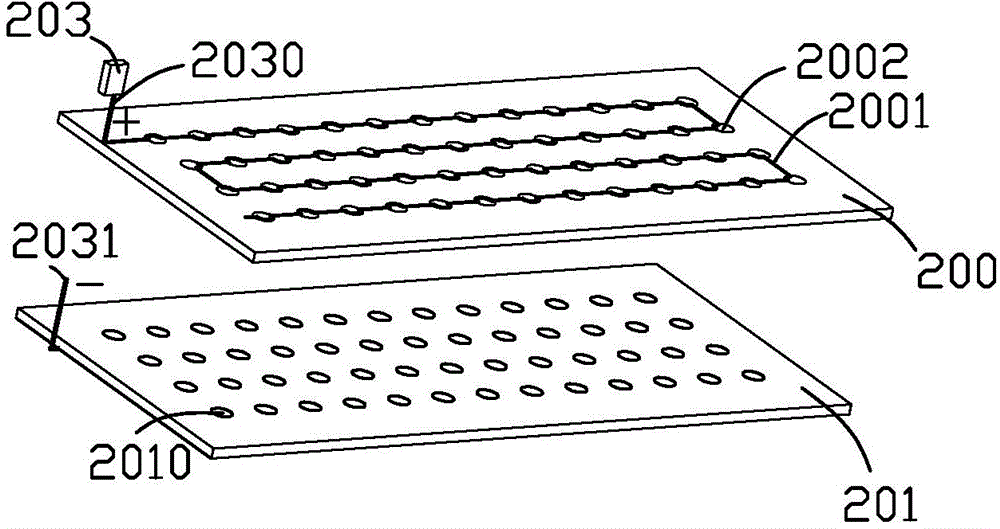

Heat radiating device

The invention provides a heat radiating device which integrally has a planar structure. The heat radiating device comprises an insulating board, a conductive board and a power supply. The power supply is connected with an external power supply for supplying high voltage to the heat radiating device. The insulating board comprises a metal filament. The power supply comprises an anode and a cathode. The anode is connected with the metal filament of the insulating board. The cathode is connected with the conductive board. The insulating board abuts against the conductive board. After the power supply supplies electric power to the heat radiating device, the metal filament ionizes adjacent air molecules for forming carbonium ions. The conductive board attracts the carbonium ions. A large amount of carbonium ions quickly move to the conductive board with negative electrons, and forced convection of air is formed, thereby realizing heat radiation.

Owner:嘉兴匠欣印刷科技有限公司

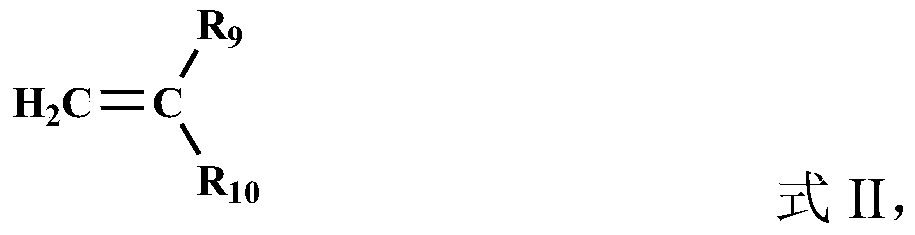

Titanium tetrachloride co-initiation system, and method for preparing high-reaction-activity polyisobutylene by using it

ActiveCN103965381AHigh α-double bond contentNarrow molecular weight distributionSimple Organic CompoundsTetrachloride

The invention relates to a titanium tetrachloride co-initiation system, and a method for preparing high-reaction-activity polyisobutylene by using it. The system is suitable for the preparation of the high-reaction-activity polyisobutylene through cationic polymerization of isobutene, an isobutene and inert solvent mixed solution or an isobutene-containing mixed light C4 fraction. An organic compound additive can be introduced into the polymerization system to efficiently and selectively remove beta-H on -CH3 adjacent to a carbonium ion at the end of an active chain in order to generate a polyisobutylene chain end alpha-double bond structure, so the high yield and high-reaction-activity polyisobutylene can be directly prepared, and the chain end alpha-double bond content can reaches above 90%.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of blue light-emitting diode

The invention provides a preparation method of blue light emitting diode and includes the following steps: a. implant the carbon ions with its energy between 20keV and 50keV and 5 multiplied by 10 to the power 16 ions / Sq cm into the N-type single crystal of silicon with its resistivity between 30 omega multiplied by centimeter and 50 omega multiplied by centimeter; b. put the N-type single crystal of Si implanted by carbonium ions into the tubular furnace, input the hydrogen or nitrogen gas or argon gas into it and passivate it for between 20 minutes and 90 minutes at the temperature of between 800deg.C and 1100deg.C; c. carry out the electrochemical corrosion for between 10 minutes and 50 minutes at constant pressure and with the current density between 20mA / Sq cm and 100mA / Sq cm, treat it with normal silicon plane and get the product. The gas flow of the hydrogen or nitrogen gas or argon gas is between 1000ml / min and 2500ml / mim and the corrosive liquor of the electrochemical corrosion is composed of the hydrochloric acid: grain alcohol=1:1-5, in amount of weight.

Owner:SHANDONG NORMAL UNIV

A kind of titanium tetrachloride co-initiation system and its method for preparing highly reactive polyisobutene

ActiveCN103965381BHigh terminal α-double bond contentReduce aciditySimple Organic CompoundsTetrachloride

The invention relates to a titanium tetrachloride co-initiation system, and a method for preparing high-reaction-activity polyisobutylene by using it. The system is suitable for the preparation of the high-reaction-activity polyisobutylene through cationic polymerization of isobutene, an isobutene and inert solvent mixed solution or an isobutene-containing mixed light C4 fraction. An organic compound additive can be introduced into the polymerization system to efficiently and selectively remove beta-H on -CH3 adjacent to a carbonium ion at the end of an active chain in order to generate a polyisobutylene chain end alpha-double bond structure, so the high yield and high-reaction-activity polyisobutylene can be directly prepared, and the chain end alpha-double bond content can reaches above 90%.

Owner:BEIJING UNIV OF CHEM TECH

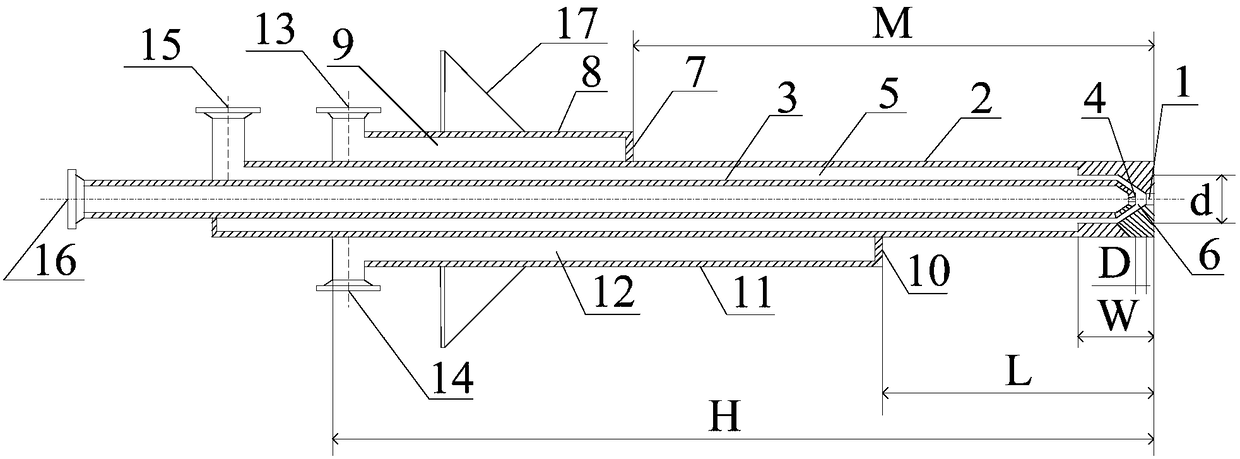

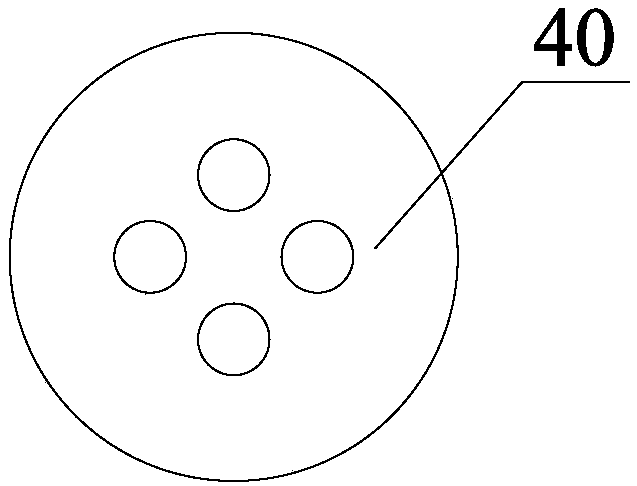

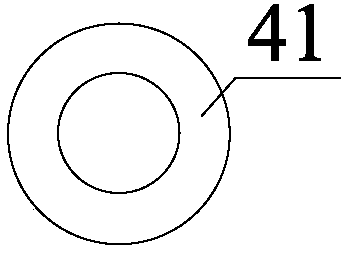

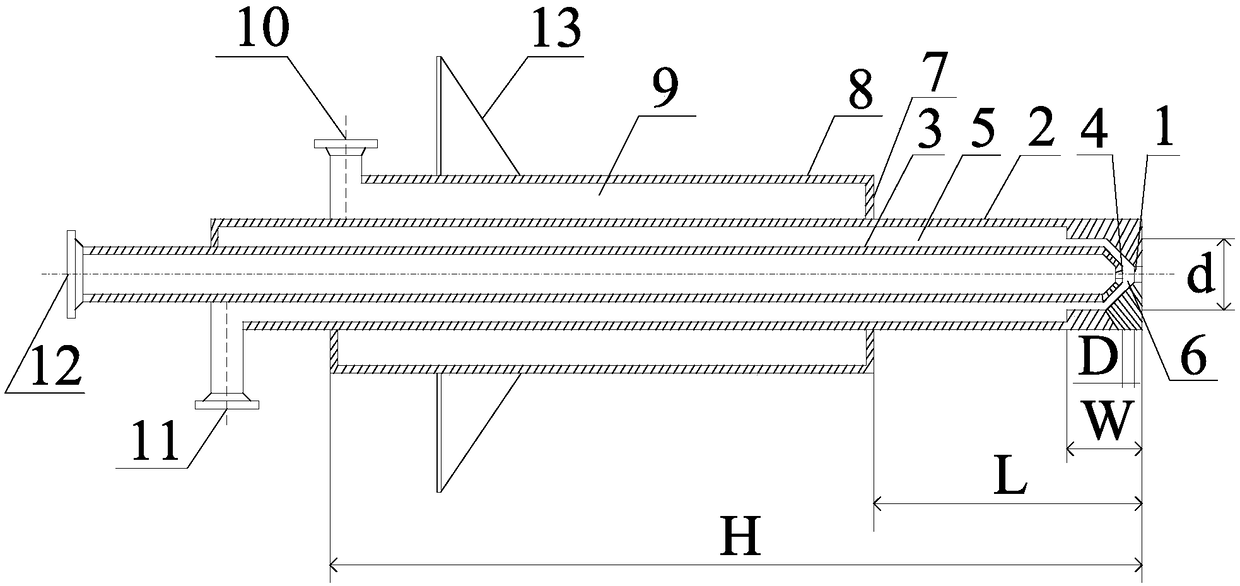

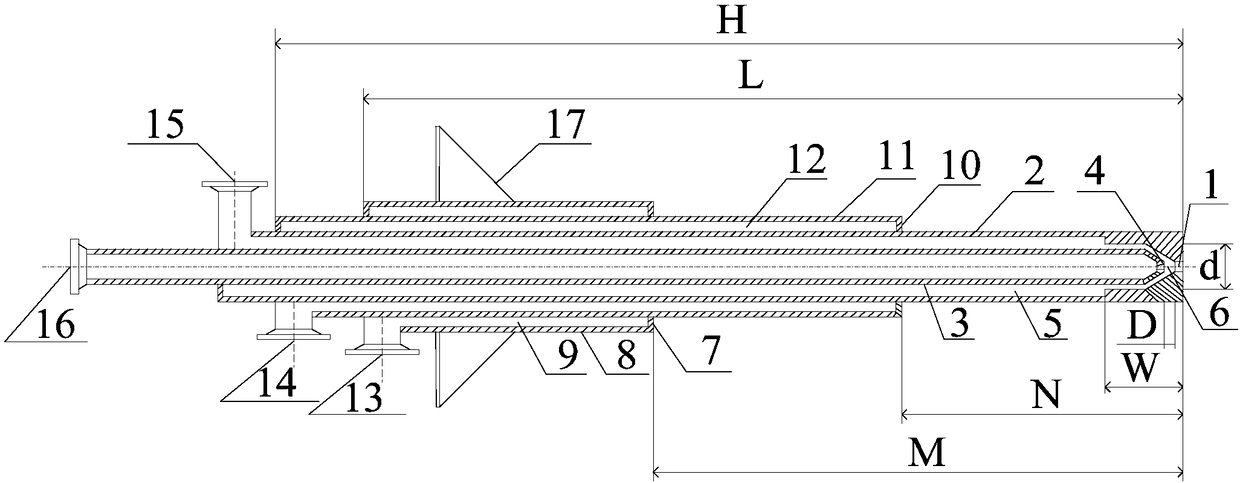

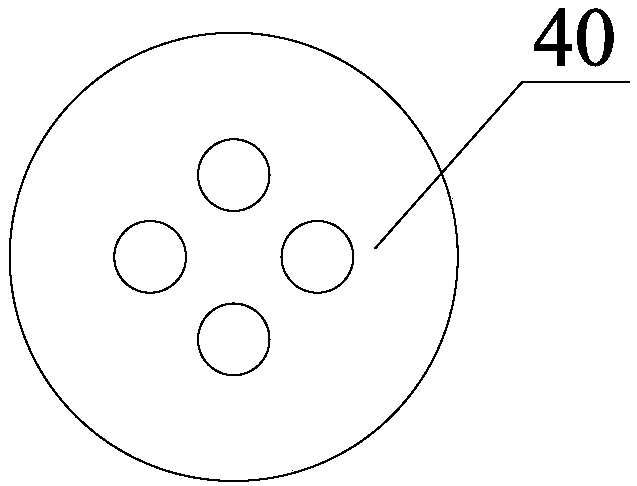

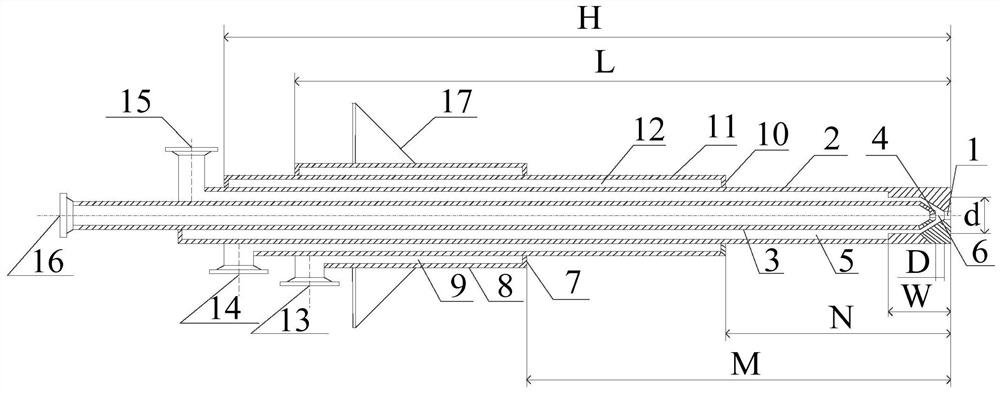

Spray nozzle for catalytic cracking and application

ActiveCN109385294AEfficient conversionReduce contact timeCatalytic crackingSpray nozzlesSpray nozzleGasoline

The invention relates to a spray nozzle for catalytic cracking and an application. The spray nozzle can simultaneously spray three raw materials and comprises a hydrocarbon oil I outer sleeve pipe, ahydrocarbon oil I inner sleeve pipe, a hydrocarbon oil I outer spray head, a hydrocarbon oil I inner spray head, a steam chamber, a hydrocarbon oil I and steam mixing chamber, a hydrocarbon oil II spray head, a hydrocarbon oil III spray head, a hydrocarbon oil II semi-circular atomizing chamber and a hydrocarbon oil III semicircular atomizing chamber. The spray nozzle can be used in a catalytic cracking lift pipe device which successively comprises a light hydrocarbon reaction zone I, a heavy hydrocarbon reaction zone and a light hydrocarbon reaction zone II from bottom to top along the axis of a reactor. According to the invention, through arrangement of the hydrocarbon oil II semi-circular atomizing chamber and the hydrocarbon oil III semi-circular atomizing chamber on the spray nozzle,the spray nozzle provided by the invention can simultaneously spray three raw materials, and can be used for experimental study of simultaneous contact and reaction of different catalytic raw materials with a catalyst;; and light hydrocarbons sprayed by the hydrocarbon oil II spray head and the hydrocarbon oil III spray head preferentially contact with the catalyst for a reaction to generate a large amount of carbonium ions, so conversion of heavy hydrocarbons is accelerated, and the spray nozzle provided by the invention has the characteristic of increasing the yield of gasoline.

Owner:PETROCHINA CO LTD

Spray nozzle for catalytic cracking lift pipe and application

The invention relates to a spray nozzle for a catalytic cracking lift pipe and an application. The spray nozzle can simultaneously spray two raw materials and comprises a hydrocarbon oil I outer sleeve pipe, a hydrocarbon oil I inner sleeve pipe, a hydrocarbon oil I outer spray head, a hydrocarbon oil I inner spray head, a steam chamber, a hydrocarbon oil I and steam mixing chamber, a hydrocarbonoil II spray head and a hydrocarbon oil II circular atomizing chamber. The spray nozzle can be applied to a catalytic cracking lift pipe device which successively comprises a light hydrocarbon reaction zone I, a heavy hydrocarbon reaction zone and a light hydrocarbon reaction zone II from bottom to top along the vertical direction of a lift pipe reactor. According to the invention, through arrangement of the hydrocarbon oil II circular atomizing chamber on the spray nozzle, the spray nozzle provided by the invention can simultaneously spray two raw materials, and can be used for the catalyticcracking lift pipe experimental device for experimental study of simultaneous contact and reaction of different catalytic raw materials with a catalyst; and light hydrocarbons sprayed by the hydrocarbon oil II spray head preferentially contact with the catalyst for a reaction to generate a large amount of carbonium ions, so conversion of heavy hydrocarbons is accelerated, and the spray nozzle provided by the invention has the characteristic of reducing the diesel-to-gasoline ratio of catalytic cracking.

Owner:PETROCHINA CO LTD

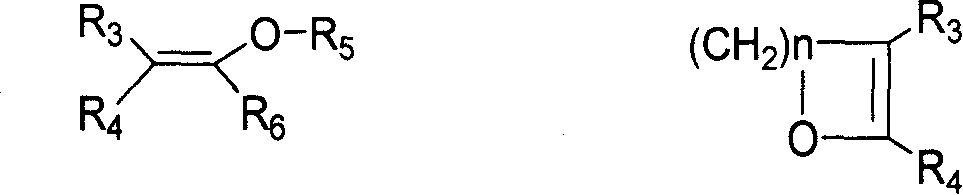

Method for removing carbonylazathia acetal protection group

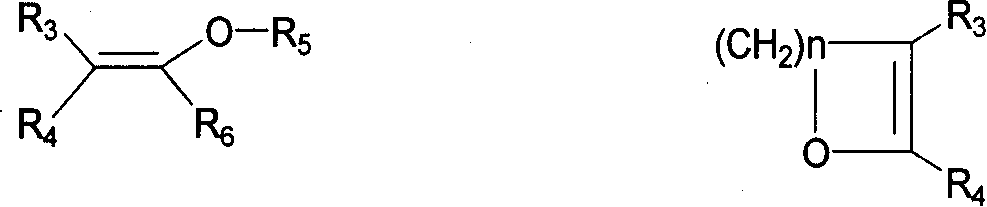

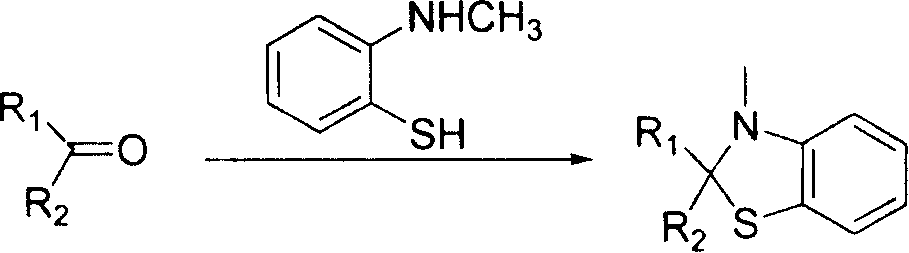

InactiveCN100398552CMild reaction conditionsSimple and fast operationCarbonyl group formation/introductionSteroidsChemical synthesisSulfur

The invention relates to a carbonyl protecting group deprotecting method. It adopts olefin ether or agent the could produce carbonium ion to take reaction with acid agent to form carbonium ion intermediate, then combining with nitrogen atoms or sulphur atoms to achieve deprotecting effect of taking further aqueous alkali open loop and hydrolyzing. The invention has mild and easy reacting condition, low cost agent, and has high yield.

Owner:FUDAN UNIV

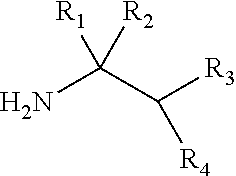

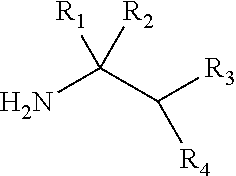

Process for preparation of tertiary alkyl primary amines

ActiveUS20160060207A1Reduce waste costsOrganic compound preparationAmino compound preparationAlkali hydroxideCarbonium ion

A method for producing an amine. The first step is contacting a cyanide, an acid, water and a substrate compound capable of generating a carbonium ion by reaction with the acid to generate a first reaction intermediate. The second step is contacting the first reaction intermediate with water to form a second reaction intermediate. The third step is removing cyanide present in the second reaction intermediate to a concentration less than 10 ppm. The fourth step is contacting the second reaction intermediate with an alkali metal hydroxide to form the amine

Owner:ROHM & HAAS CO +1

A kind of styrene-isomonoolefin-styrene triblock copolymer and preparation method thereof

ActiveCN106317349BHigh biphenyl copolymer contentLow homopolymer contentOrganic solventCationic polymerization

The invention relates to a styrene-isomonoolefin-styrene triblock copolymer and a preparation method thereof. The method comprises the following steps: (1) in the presence of an organic solvent and titanium tetrachloride, carrying out first cationic polymerization reaction on isomonoolefin to obtain a polymeric system containing polyisomonoolefin with reaction activities at the tail end; and (2) contacting the polymeric system with a styrene-containing solution, and carrying out second cationic polymerization reaction, wherein the first cationic polymerization reaction in the step (1) also comprises the step of introducing an initiator system, and the initiator system contains at least one compound capable of providing carbonium ions and at least one activator. The method can effectively lower the generation of the styrene homopolymer and styrene bi or high copolymer, thereby effectively enhancing the block polymerization efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparation of tertiary alkyl primary amines

ActiveUS9617200B2Reduce waste costsOrganic compound preparationAmino compound preparationCyanideReaction intermediate

A method for producing an amine. The first step is contacting a cyanide, an acid, water and a substrate compound capable of generating a carbonium ion by reaction with the acid to generate a first reaction intermediate. The second step is contacting the first reaction intermediate with water to form a second reaction intermediate. The third step is removing cyanide present in the second reaction intermediate to a concentration less than 10 ppm. The fourth step is contacting the second reaction intermediate with an alkali metal hydroxide to form the amine.

Owner:ROHM & HAAS CO +1

N-butane hydroisomerization catalyst, and preparation method and application thereof

ActiveCN102500413BReduce cloggingChange the pore structureMolecular sieve catalystsHydrocarbon oils refiningAlkaneIsomerization

The invention discloses an n-butane hydroisomerization catalyst, and a preparation method and application thereof. The catalyst is prepared from 5-35 wt% of modified Y molecular sieve, 45-75 wt% of SAPO-11 molecular sieve, 0.05-5.0 wt% of noble metal active component, 0.05-5.0 wt% of assistant active metal component tin and 10-20 wt% of aluminum oxide adhesive, wherein the noble metal active component is dispersed in the modified Y molecular sieve and SAPO-11 molecular sieve. Since the modified Y molecular sieve is added, alkane molecules can generate carbonium ions required by the reaction process more easily; the modified Y molecular sieve has large pore canals, and thus, can effectively decrease the blocked pore canals in the molecular sieve and change the pore canal structure of the catalyst support; and the pore size of the Y molecular sieve can be modified and adjusted to change the pore volume of the molecular sieve and improve the diffusion restriction of the pore canals on the reactant or product molecules, thereby effectively performing the isomerization reaction and obtaining the high-yield isomerizate.

Owner:LUOYANG RONGHUI CHEM TECH CO LTD

Spray nozzle for catalytic cracking experiment and application

Owner:PETROCHINA CO LTD

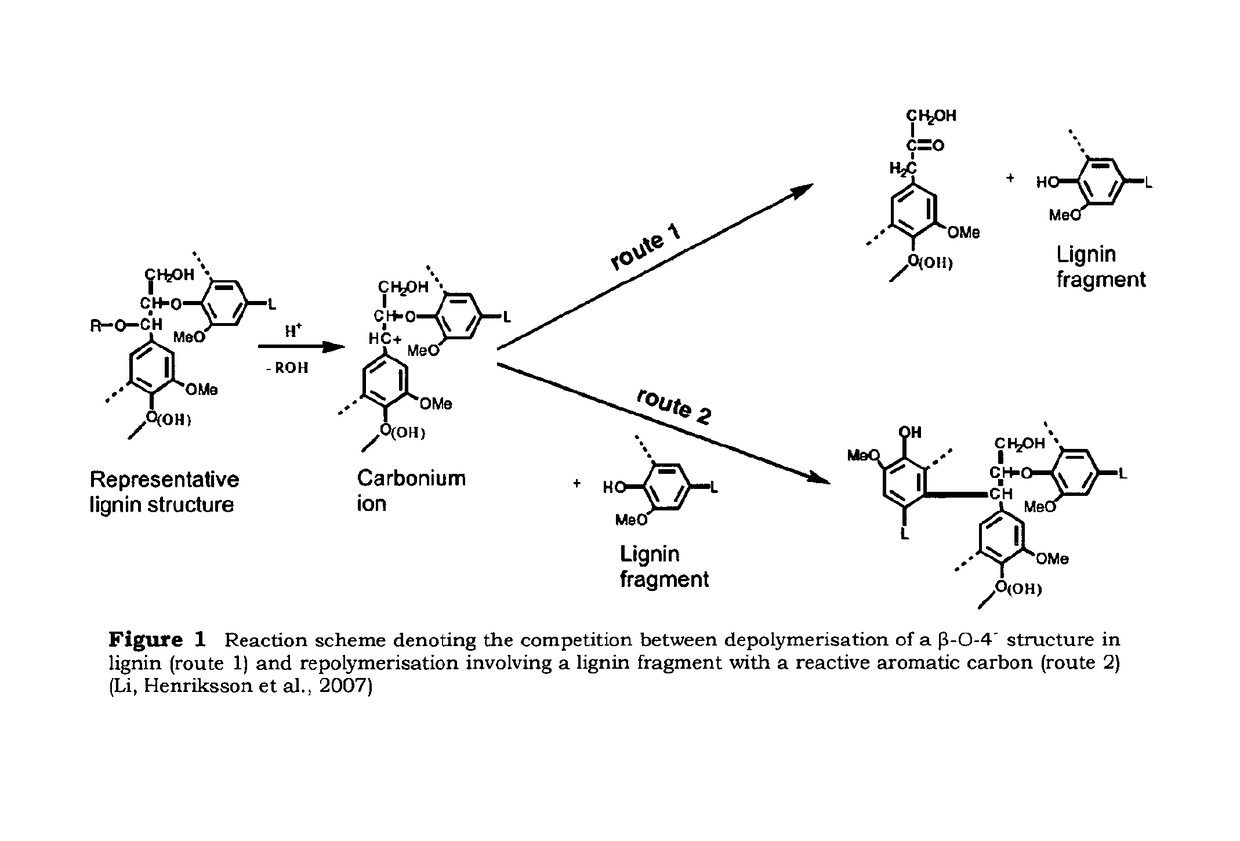

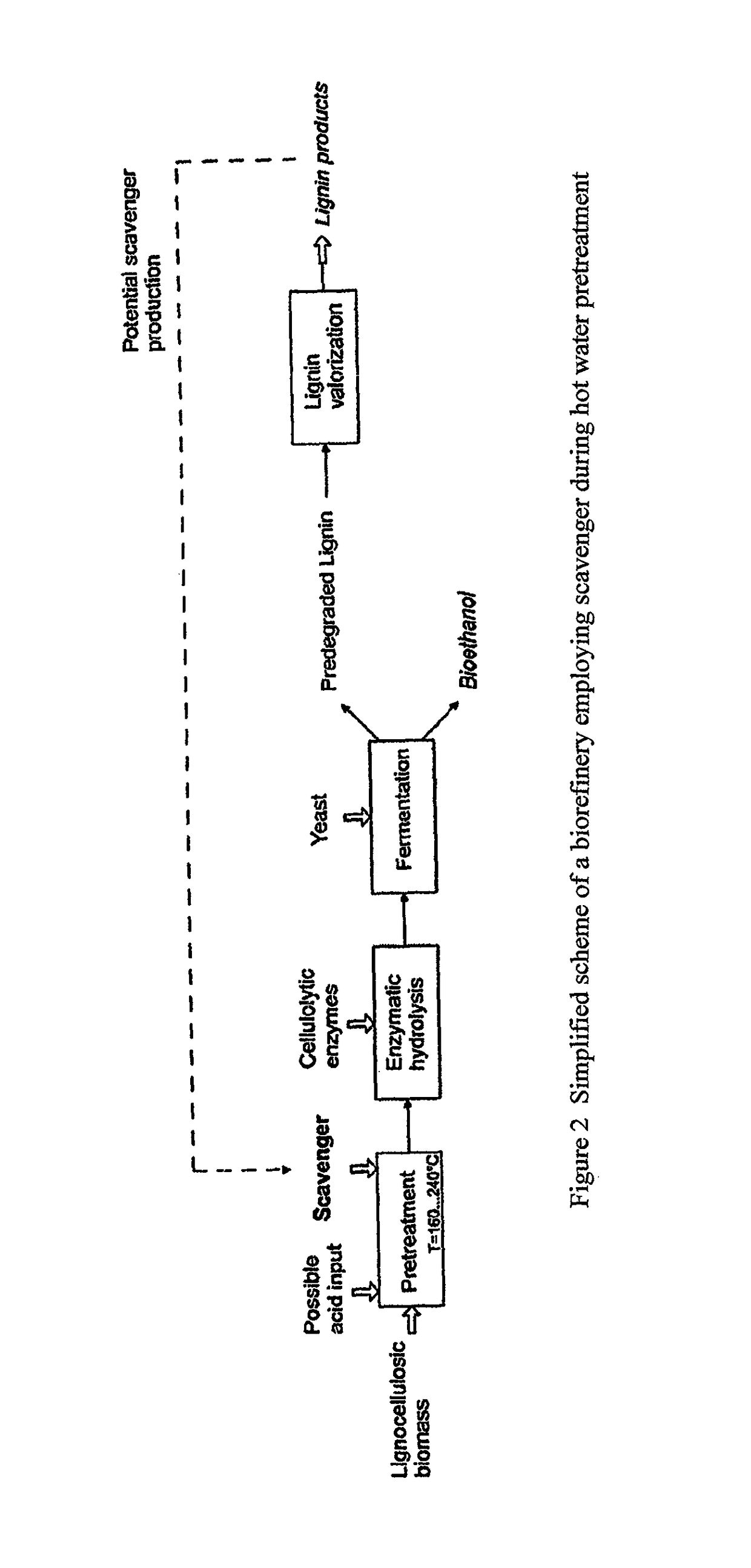

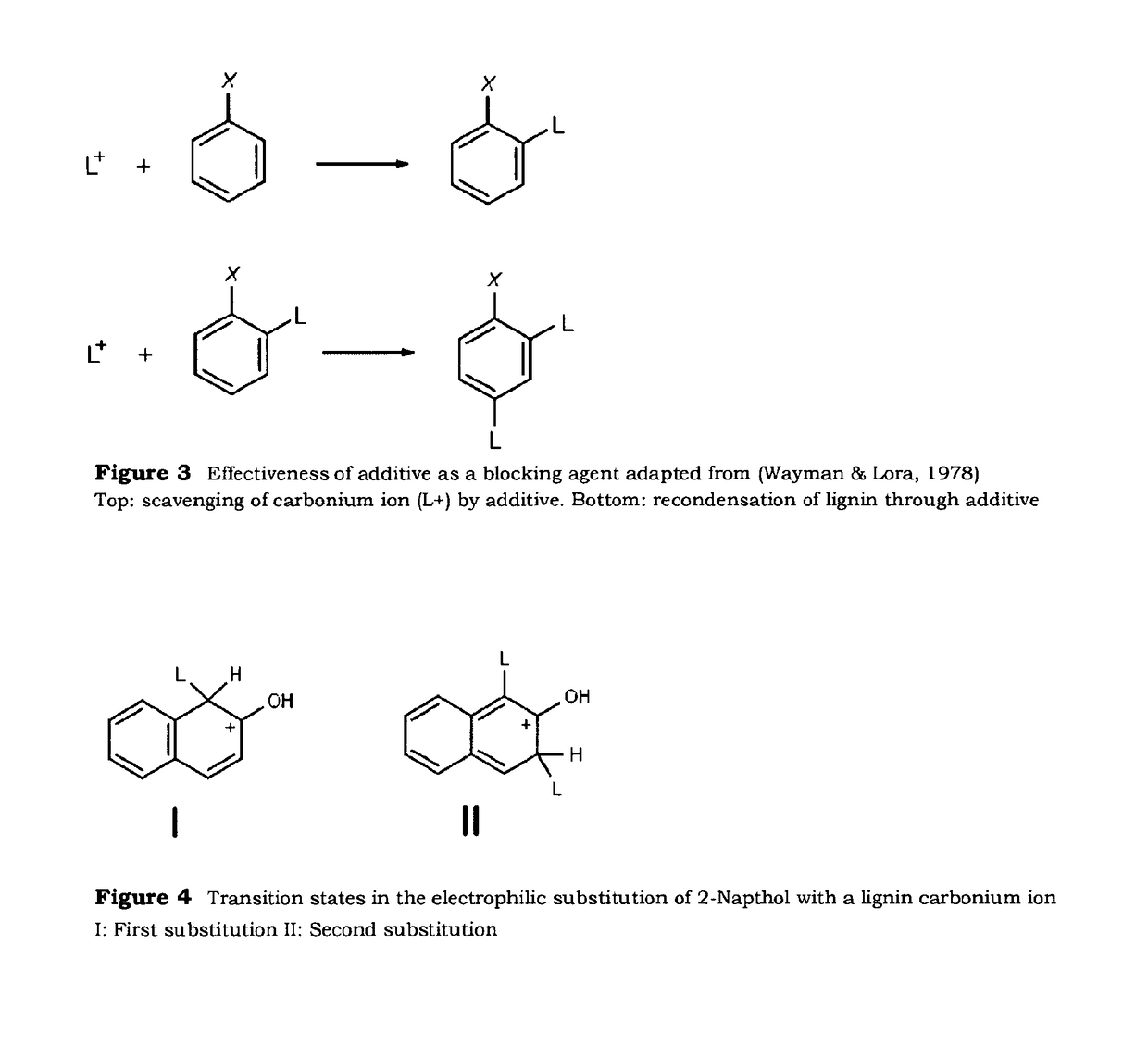

Use of carbonium ion scavengers in the treatment of lignocellulosic biomass

The disclosure describes a process for the production of a cellulosic feedstock for enzymatic hydrolysis and / or a lignin fraction for chemicals production, characterized in that a) the raw material is lignocellulosic biomass b) the biomass is treated in hot water c) at least one carbonium ion scavenger is present in the treatment.

Owner:ETH ZZURICH

A nozzle for catalytic cracking test and its application

ActiveCN109385295BEvenly dispersedEven contactCatalytic crackingSpray nozzlesPtru catalystSpray nozzle

The invention relates to a spray nozzle for a catalytic cracking experiment and an application. The spray nozzle can simultaneously spray three raw materials and comprises a hydrocarbon oil I outer sleeve pipe, a hydrocarbon oil I inner sleeve pipe, a hydrocarbon oil I outer spray head, a hydrocarbon oil I inner spray head, a hydrocarbon oil II sleeve pipe, a hydrocarbon oil III sleeve pipe, a steam chamber, a hydrocarbon oil I and steam mixing chamber, a hydrocarbon oil II spray head, a hydrocarbon oil III spray head, a hydrocarbon oil II circular atomizing chamber and a hydrocarbon oil III circular atomizing chamber. According to the invention ,through arrangement of the hydrocarbon oil II circular atomizing chamber and the hydrocarbon oil III circular atomizing chamber on the spray nozzle, the spray nozzle provided by the invention can simultaneously spray three raw materials, and can be used for an experimental for experimental study of simultaneous contact and reaction of different catalytic raw materials with a catalyst; and light hydrocarbons sprayed by the hydrocarbon oil II spray head and the hydrocarbon oil III spray head preferentially contact with the catalyst for a reaction to generate a large amount of carbonium ions, so conversion of heavy hydrocarbons is accelerated, and the spray nozzle provided by the invention has the characteristics of increasing the yield of liquefied gas, gasoline and low-carbon olefins and improving total liquid yield and conversion rate.

Owner:PETROCHINA CO LTD

Method for converting normal olefine into isomeric olefine with gold-supported molecular sieve catalyst

InactiveCN103113178AEasy to prepareSmall gold particlesHydrocarbon by isomerisationMolecular sieve catalystsDispersityDeposition precipitation

The invention belongs to the technical field of catalysts, and relates to a method for converting normal olefine into isomeric olefine with a gold-supported molecular sieve catalyst. After a molecular sieve is subjected to sufficient negative-pressure degasification purifying treatment, a gold precursor is supported onto the molecular sieve support by a negative-pressure deposition precipitation process to obtain the uniformly-dispersed small-granularity supported nanogold catalyst. The molecular sieve is a silica-rich zeolite molecular sieve. The gold-supported catalyst prepared by the deposition precipitation process under negative-pressure conditions is beneficial to purifying the internal and external surfaces and pores of the molecular sieve, so that the Au can easily enter the pores of the molecular sieve, thereby achieving the goal of high dispersity. By using the method, the normal olefine can obtain protons at the acid center under the dual functions of the metal and support to form carbonium ions, and the carbonium ions are subjected to framework isomerization to generate the isomeric olefine.

Owner:DALIAN UNIV OF TECH

Preparation method of adamantanols

ActiveCN101891570BShorten the timeHigh yieldPreparation by oxidation reactionsHydroxy group formation/introductionResistAlcohol

The invention provides a method for production of adamantanol. The adamantane reacts in a mixing solution containing a fuming sulfuric acid and an organic nitrile compound and the obtained reaction solution is hydrolyzed. The adamantanol is industrially beneficially produced by the adamantane at high yield in short time without using a large amount of fuming sulfuric acid and dear carbonium ion generation compound. The adamantanol is used as the raw material of a medicine intermediate and a monomer for a photoresist, the raw material of a photochromic compound and the raw material of a coating, a cement, a binder, a film and an adsorbing material.

Owner:OSAKA ORGANIC CHEM INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com