A kind of styrene-isomonoolefin-styrene triblock copolymer and preparation method thereof

A technology of isomonoolefin and styrene, which is applied in the field of styrene-isomonoolefin-styrene triblock copolymer and its preparation, can solve the problems of high block efficiency, low content, and decreased block copolymerization efficiency, etc. To achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a kind of preparation method of styrene-isomonoolefin-styrene triblock copolymer, the method comprises:

[0023] (1) In the presence of an organic solvent and titanium tetrachloride, the isomonoolefin is subjected to the first cationic polymerization reaction to obtain a polymerization system containing polyisomonoolefin with reactive terminals;

[0024] (2) contacting the polymerization system with a solution containing styrene to carry out the second cationic polymerization reaction;

[0025] Wherein, the first cationic polymerization described in step (1) also includes introducing an initiator system, which contains at least one compound capable of providing carbocations and at least one activator,

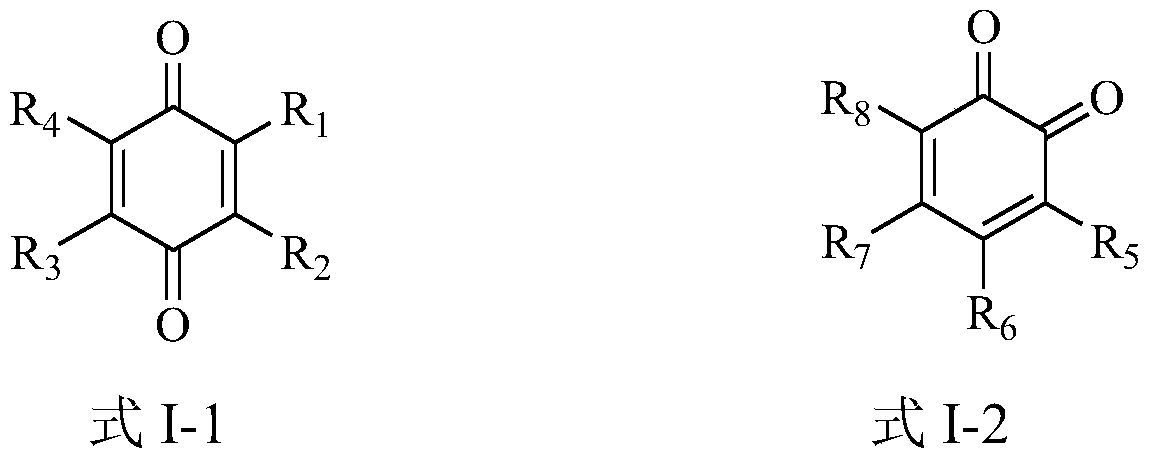

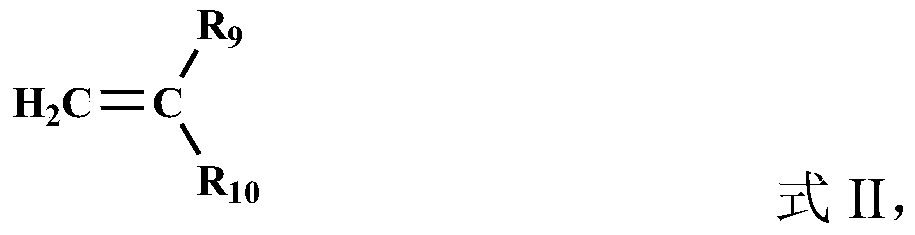

[0026] The activator is selected from compounds shown in formula I-1 and compounds shown in formula I-2,

[0027]

[0028] In formula I-1 and formula I-2, R 1 -R 8 each independently -H, -X 1 , -NO 2 , and-CN,X 1 and x 2 each independen...

Embodiment 1

[0087] This example is used to illustrate the triblock copolymer of the present invention and its preparation method.

[0088] (1) Configuration of initiator solution: the concentration of tetrachloro-p-benzoquinone and p-dicumyl methyl ether configured in methylene chloride to obtain the concentration of 0.008mol / L and p-dicumyl methyl ether It is a 0.01mol / L solution and placed in a cold bath at -80°C for later use.

[0089]Under the protection of nitrogen, put the solution of isobutene (175mL n-hexane + 175mL dichloromethane + 0.58mol isobutene) in a cold bath at -80°C, add 50mL of the initiator solution prepared above, continue stirring for 20 minutes, and then add After 0.02 mol of titanium tetrachloride was polymerized at -80°C for 60 minutes, the measured conversion rate of isobutene is shown in Table 1.

[0090] (2) Add 100 mL of styrene solution (containing 20 mL of styrene (about 0.17 mol) + 44 mL of n-hexane + 44 mL of dichloromethane) pre-refrigerated at -80 ° C t...

Embodiment 2

[0100] This example is used to illustrate the triblock copolymer of the present invention and its preparation method.

[0101] (1) Configuration of initiator solution: configure 2,3-dichloro-5,6-dicyano-p-benzoquinone and p-dicumyl methyl ether in dichloromethane to obtain 2,3-dichloro-5,6 - a solution in which the concentration of dicyano-p-benzoquinone is 0.02mol / L and the concentration of p-dicumyl ether is 0.01mol / L, and placed in a cold bath at -50°C for subsequent use.

[0102] Under the protection of nitrogen, put the solution of isobutene (150mL n-hexane + 180mL dichloromethane + 0.58mol isobutene) in a cold bath at -50°C, add 50mL of the initiator solution prepared above, continue stirring for 20 minutes, and then add After 0.02 mol of titanium tetrachloride was polymerized at -50°C for 70 minutes, the measured conversion rate of isobutene is shown in Table 1.

[0103] (2) Add 100 mL of styrene solution (containing 20 mL of styrene (about 0.17 mol) + 40 mL of n-hexan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com