Auxiliary capable of increasing clean oil yield and used for catalytic cracking

A catalytic cracking, light oil technology, applied in catalytic cracking, cracking, petroleum industry and other directions, can solve the problems of deposition, human health, antimony loss, etc., to reduce deposition, prolong service life, and add less effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

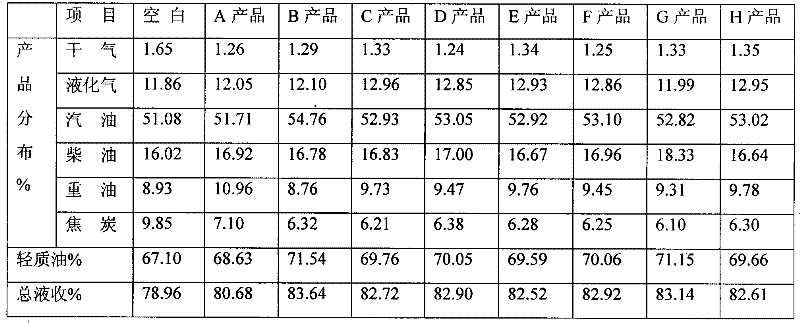

Embodiment 1

[0033] An auxiliary agent for increasing the yield of light oil for catalytic cracking is prepared by a method comprising the following steps:

[0034] 50g monosuccinimide (5%), 100g 2,6-di-tert-butyl-p-cresol (10%), 50g N,N-dialkylaminomethylene benzotriazole (5%), 300g Vanadium naphthenate (30%) and 500g diesel oil (50%) were added to a container and heated to 45° C., then stirred at a constant temperature. After stirring and mixing evenly, cooled to room temperature, filtered to obtain product A.

Embodiment 2

[0036] An auxiliary agent for increasing the yield of light oil for catalytic cracking is prepared by a method comprising the following steps:

[0037] 150g borated succinimide (15%), 250g 2,6-di-tert-butylphenol (25%), 150g N,N-dialkylaminomethylene benzotriazole (15%), 350g ring Add cerium alkanoate (35%) and 100 g of diesel oil (10%) into a container, heat to 45° C. and then stir at a constant temperature. After stirring and mixing evenly, cool to room temperature and filter to obtain product B.

Embodiment 3

[0039] An auxiliary agent for increasing the yield of light oil for catalytic cracking is prepared by a method comprising the following steps:

[0040] 120g bis-succinimide (12%), 180g 4,4'-methylenebis(2,6-di-tert-butylphenol) (18%), 120g 2-mercaptothiadiazole (12%) , 350g ytterbium naphthenate (35%), 230g diesel oil (23%), add in the container and be heated to 45 ℃ after constant temperature stirring, after stirring and mixing, be cooled to room temperature, filter and obtain C product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com