Preparation method of adamantanols

A technology of adamantanol and adamantane, which is applied in the field of preparing adamantanols, can solve problems such as increased raw material costs and expensive catalysts, and achieve high yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

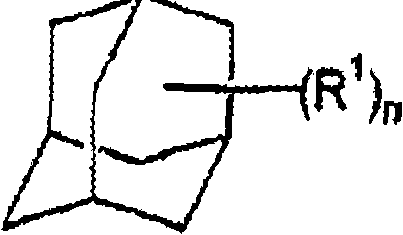

Image

Examples

Embodiment 1

[0050] 30 mL (582 mmol) of 25% by mass fuming sulfuric acid was added to a 100 mL four-necked flask, 2.4 g (58.5 mmol) of acetonitrile and 6.0 g (44.1 mmol) of adamantane were added, and the mixture was reacted at a reaction temperature of 25° C. for 3 hours. It should be noted that the molar ratio of oleum to the raw material adamantane was 13.2 (=582 / 44.1).

[0051] Next, the reaction liquid was added dropwise to 90 g of water at 70° C. charged in a 4 L four-necked flask. When the dropwise addition was completed, the temperature of the mixed liquid of water and the reaction liquid was 75°C. After the dropwise addition was completed, the hydrolysis was completed by stirring at 80° C. for 30 minutes. After cooling to room temperature, the precipitated crystals were filtered and dried to obtain 6.6 g of crystals.

[0052] According to gas chromatography analysis, the crystals were 1-adamantanol with a GC purity of 99.6%, and the yield was 98%.

Embodiment 2

[0054] Except having adjusted the addition amount of acetonitrile to 3.6 g (87.7 mmol), the same operation as Example 1 was performed. As a result, 6.5 g of 1-adamantanol with a GC purity of 99.7% was obtained, and the yield was 97%.

Embodiment 3

[0056] Except having made reaction temperature into 40 degreeC, the same operation as Example 1 was performed. As a result, 6.2 g of 1-adamantanol with a GC purity of 97.6% was obtained, and the yield was 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com