Heat radiating device

A technology of heat dissipation device and heat dissipation hole, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of reducing the efficiency and life of components, unable to discharge heat energy, and bringing heat energy out of the product.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

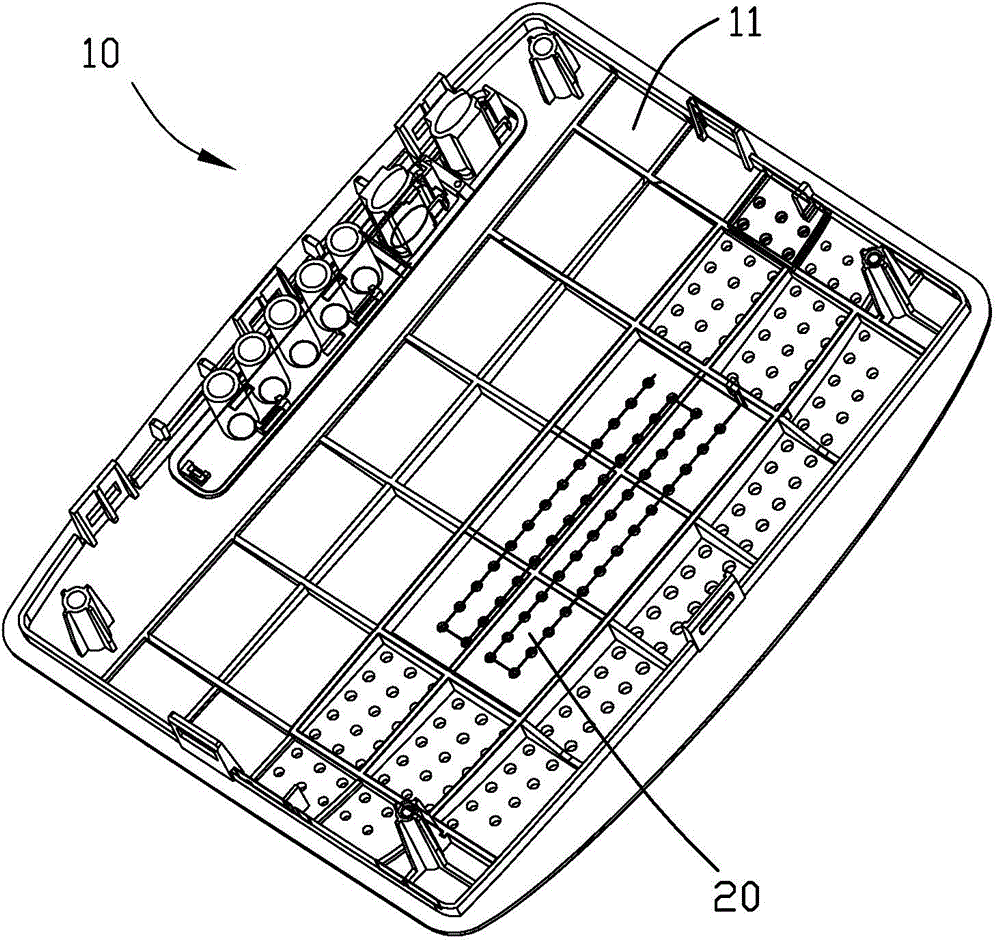

[0031] see figure 1 , the heat dissipation device 20 provided by the present invention is used to dissipate heat to the electronic device 10 , the electronic device 10 includes a casing 11 , and the heat dissipation device 20 is installed in the casing 11 .

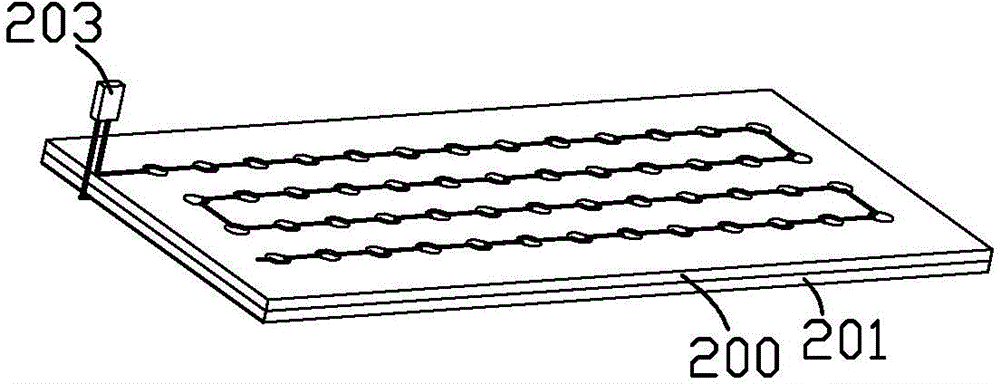

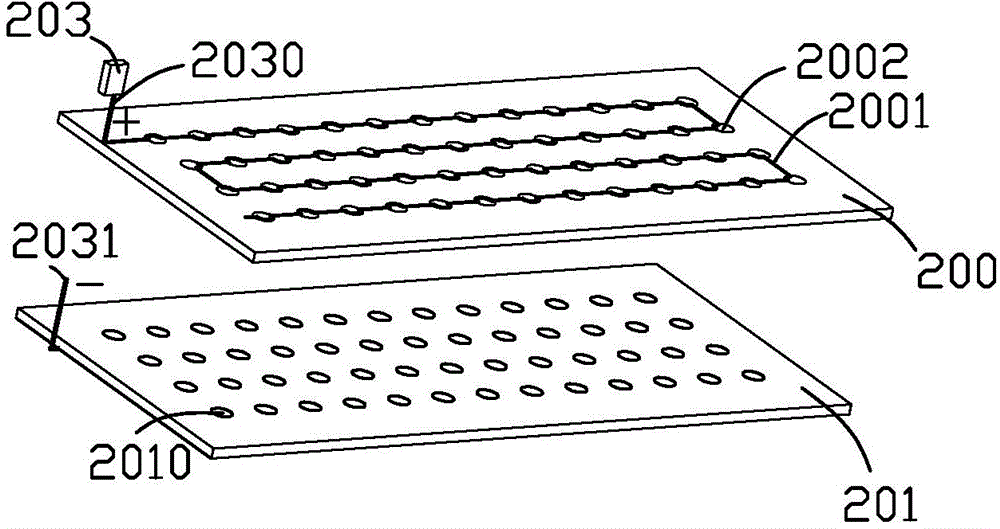

[0032] see figure 2 and image 3 , the heat dissipation device 20 is a flat plate structure as a whole, and the heat dissipation device 20 includes an insulating plate 200 , a conductive plate 201 and a power supply 203 . The power supply 203 includes a positive pole 2030 and a negative pole 2031. The positive pole 2030 is electrically connected to the circuit laid on the insulating plate 200, and the negative pole 2031 is electrically connected to the conductive plate 201. The power supply 203 provides piezoelectricity for the cooling device 20. In this embodiment, the voltage is High voltage electricity, high voltage electricity can be provided by common small transformers.

[0033] The insulating plate 200 is bonde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com