Metal-metallic oxide pH electrode and method for making same

An oxide and oxide film technology, applied in the direction of electrochemical variables of materials, etc., can solve the problem of standard electrode potential drift and resistance to oxidation/reduction substances. Equipment and targets are expensive and other problems, to achieve the effect of not easy to break, low price, easy to mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

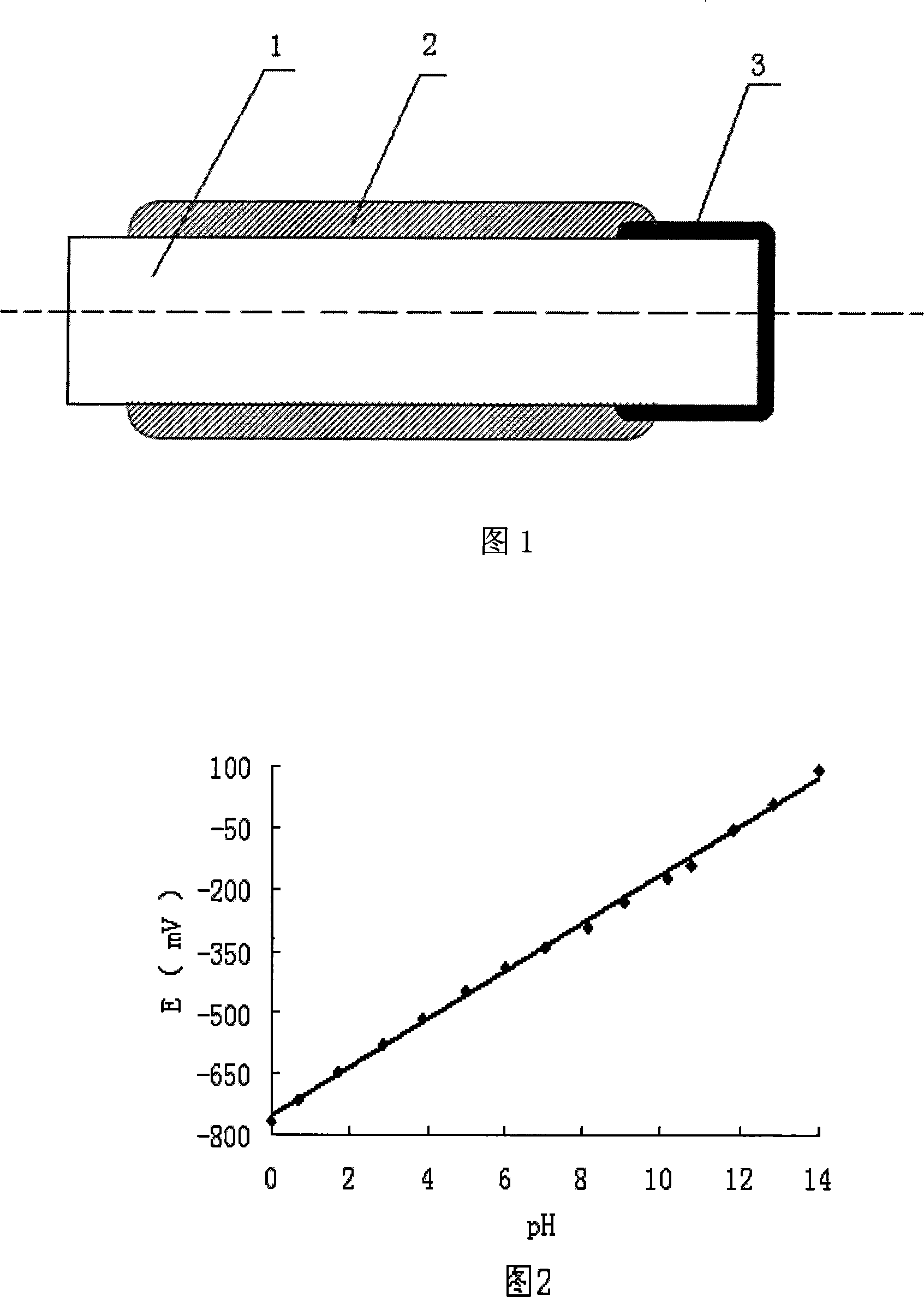

[0026] Example 1: Ir / IrO x Fabrication of the pH electrode

[0027] (1) Put one end of a section of Ir wire matrix on sandpaper and grind it for 10 minutes, put the polished Ir wire into a 5% NaOH solution and boil for 20 minutes, then heat it to boiling in a concentrated HCl solution and keep it for 20 minutes, Finally, rinse with secondary water and place in absolute ethanol for later use.

[0028] (2) Coat 10 μL of 0.5 g / L ammonium iridite chloroiridite precursor solution on the surface of the treated Ir wire, dry it at 60 °C for 1 hour, repeat 3 times, and then place it in the muffle furnace with 2°C / min temperature programming, heating to 450°C, and keeping the temperature for 2 hours, then lowering to room temperature, sealing the side of the metal substrate Ir with insulating varnish to obtain Ir / IrO x pH electrode.

Embodiment 2

[0029] Example 2: Ti / IrO x Fabrication of the pH electrode

[0030] (1) Put one end of the Ti wire matrix with a diameter of 2mm on sandpaper for 10 minutes, put the polished Ti wire into 10% NaOH solution and boil for 5 minutes, then heat to boiling in concentrated HCl solution, and keep for 10 Minutes, finally rinsed with secondary water, placed in absolute ethanol for later use.

[0031] (2) Coat 10 μL of 0.1 g / L ammonium chloroiridite solution on the surface of the treated Ti wire, dry it at 80 °C for 0.5 hour, repeat 5 times, and then heat it in the muffle furnace at 0.5 °C / min temperature program, heated to 750 ° C, and kept at a constant temperature for 0.5 hours, then lowered to room temperature, and the side of the metal substrate Ti was encapsulated with insulating varnish to obtain Ti / IrO x pH electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com