Wall flow exhaust particle filtering and electricalloy heating post-regeneration treating device for diesel engine

A post-processing device and wall-flow technology, applied in exhaust devices, noise reduction devices, mechanical equipment, etc., can solve the problems of high fuel quality requirements, complex structure, easy catalyst poisoning, etc., and achieve significant social and economic benefits. High filtration efficiency and vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

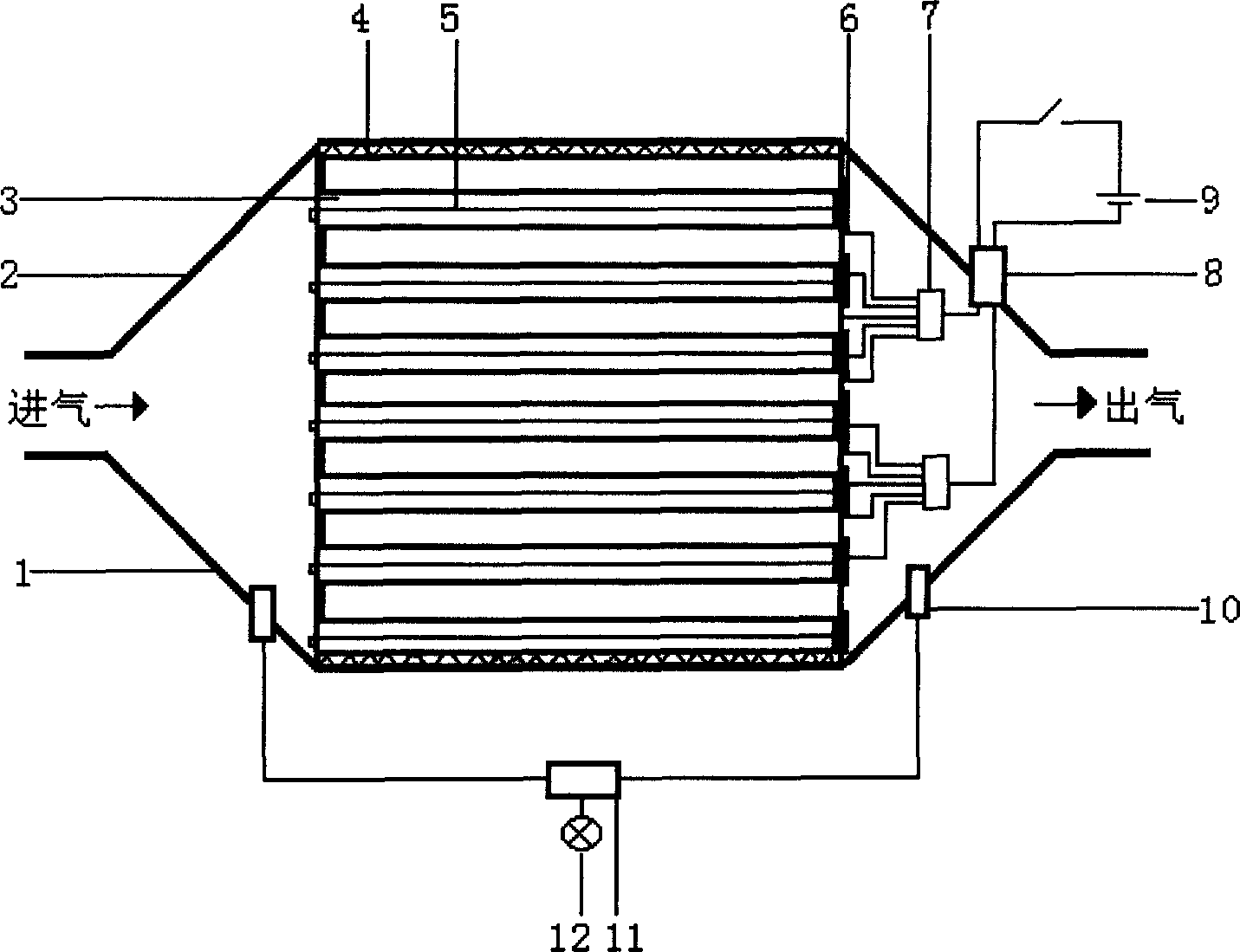

[0009] Such as figure 1 As shown, the present invention mainly includes: lower housing 1, upper housing 2, wall-flow honeycomb ceramics 3, metal wire 4, heating wire 5, connecting piece 6, metal chuck 7, conduit 8, power supply 9, pressure sensor 10. Electronic control device 11, warning light 12, the wall-flow honeycomb ceramic 3 is cylindrical, and the holes at the inlet end are blocked alternately. After the exhaust gas of the diesel engine enters from the inlet end of the wall-flow honeycomb ceramic Particles are filtered when the micropores on the top pass through, and the heating wire 5 is made into a U shape. The heating wire 5 is inserted from the air inlet direction along the adjacent diagonal filter holes of the wall-flow honeycomb ceramic 3, and passes through the outlet end of the wall-flow honeycomb ceramic 3. The connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com