Regeneration technology for molecular distillation treatment of spent lubrication oil

A technology of molecular distillation and waste lubricating oil, applied in lubricating compositions and other directions, can solve the problems of low output of lubricating oil, high investment cost, environmental pollution, etc., and achieve the effects of high regeneration efficiency, low operating cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

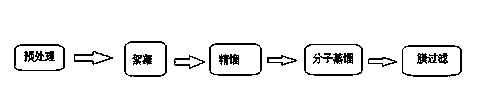

[0023] A regeneration process for waste lubricating oil after molecular distillation treatment is characterized in that it comprises the following steps:

[0024] Pretreatment: first put the waste lubricating oil into the settling tank for sedimentation, then take the oily mixture in the upper layer and put it into the plate and frame filter for filtering to obtain the treatment liquid;

[0025] Flocculation: heat the treatment solution to 120°C, during the heating process, add one-fifth of the organic flocculant for every 20°C increase in temperature until the organic flocculant is added;

[0026] Rectification: After degassing and drying the treated liquid after flocculation, it is transferred to a rectification tower for rectification;

[0027] Molecular distillation: carry out multi-stage molecular distillation on the distilled lubricating oil again;

[0028] Membrane filtration: The lubricating oil after molecular distillation is subjected to membrane filtration to obtai...

Embodiment 2

[0034] A regeneration process for waste lubricating oil after molecular distillation treatment is characterized in that it comprises the following steps:

[0035] Pretreatment: first put the waste lubricating oil into the settling tank for sedimentation, then take the oily mixture in the upper layer and put it into the plate and frame filter for filtering to obtain the treatment liquid;

[0036] Flocculation: heat the treatment solution to 150°C, during the heating process, add one-fifth of the organic flocculant for every 20°C increase in temperature until the organic flocculant is added;

[0037] Rectification: After degassing and drying the treated liquid after flocculation, it is transferred to a rectification tower for rectification;

[0038] Molecular distillation: carry out multi-stage molecular distillation on the distilled lubricating oil again;

[0039] Membrane filtration: The lubricating oil after molecular distillation is subjected to membrane filtration to obtai...

Embodiment 3

[0045] A regeneration process for waste lubricating oil after molecular distillation treatment is characterized in that it comprises the following steps:

[0046] Pretreatment: first put the waste lubricating oil into the settling tank for sedimentation, then take the oily mixture in the upper layer and put it into the plate and frame filter for filtering to obtain the treatment liquid;

[0047] Flocculation: heat the treatment solution to 170°C, during the heating process, add one-fifth of the organic flocculant for every 20°C increase in temperature until the organic flocculant is added;

[0048] Rectification: After degassing and drying the treated liquid after flocculation, it is transferred to a rectification tower for rectification;

[0049] Molecular distillation: carry out multi-stage molecular distillation on the distilled lubricating oil again;

[0050] Membrane filtration: The lubricating oil after molecular distillation is subjected to membrane filtration to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com