Preparation method of super-hydrophobic, super-oleophobic and high transparency triple-function coating film

A superhydrophobic, superoleophobic, high light transmittance technology, applied in the field of superhydrophobic superoleophobic high light transmittance triple function self-cleaning silica-based coating film and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

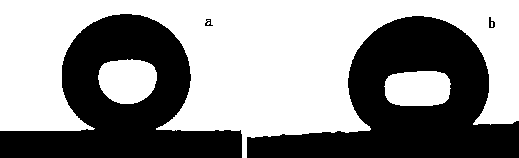

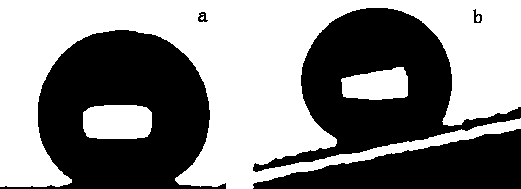

[0023] This example is the preparation of a super-hydrophobic, super-oleophobic and high-transmittance triple-functional coating film. The specific process is: use concentrated sulfuric acid (98wt%) and hydrogen peroxide (30wt%) aqueous solution to prepare a glass washing solution at a volume ratio of 3:1, soak the glass substrate in the glass washing solution for 5 minutes, and then wash it in deionized water and acetone respectively. Ultrasonic for 20 minutes, then treated with 5 mol / L sodium hydroxide aqueous solution at room temperature for 5 minutes, washed with deionized water, and dried by blowing at room temperature to obtain an activated glass substrate;

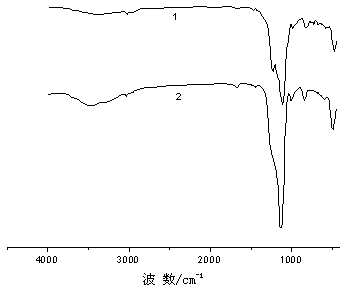

[0024] 2mL tetraethyl orthosilicate (Si(OCH 2 CH 3 ) 4 ) with 1mL dimethyldiethoxysilane ((CH 3 ) 2 Si(OCH 2 CH 3 ) 2 ) mixed, added to 25mL of absolute ethanol, stirred evenly to obtain solution A; 3mL of concentrated ammonia water (25wt%) was added to 25mL of absolute ethanol, stirred evenly to obtain solutio...

Embodiment 2

[0026] This example is the preparation of a super-hydrophobic, super-oleophobic and high-transmittance triple-functional coating film. The specific process is: use concentrated sulfuric acid (98wt%) and hydrogen peroxide (30wt%) aqueous solution to prepare a glass washing solution at a volume ratio of 3:1, soak the glass substrate in the glass washing solution for 5 minutes, and then wash it in deionized water and acetone respectively. Ultrasonic for 20 minutes, then treated with 5 mol / L sodium hydroxide aqueous solution at room temperature for 5 minutes, washed with deionized water, and dried by blowing at room temperature to obtain an activated glass substrate; 2 mL of ethyl orthosilicate (Si(OCH 2 CH 3 ) 4 ) with 1mL dimethyldiethoxysilane ((CH 3 ) 2 Si(OCH 2 CH 3 ) 2 ) mixed, added to 25mL of absolute ethanol, stirred evenly to obtain solution A; 4mL of concentrated ammonia water (25wt%) was added to 25mL of absolute ethanol, stirred evenly to obtain solution B; slow...

Embodiment 3

[0029] This example is the preparation of a super-hydrophobic, super-oleophobic and high-transmittance triple-functional coating film. The specific process is: use concentrated sulfuric acid (98wt%) and hydrogen peroxide (30wt%) aqueous solution to prepare a glass washing solution at a volume ratio of 3:1, soak the glass substrate in the glass washing solution for 5 minutes, and then wash it in deionized water and acetone respectively. Ultrasonic for 20 minutes, then treated with 5 mol / L sodium hydroxide aqueous solution at room temperature for 5 minutes, washed with deionized water, and dried by blowing at room temperature to obtain an activated glass substrate; 2 mL of ethyl orthosilicate (Si(OCH 2 CH 3 ) 4 ) with 1mL dimethyldiethoxysilane ((CH 3 ) 2 Si(OCH 2 CH 3 ) 2 ) mixed, added to 25mL of absolute ethanol, stirred evenly to obtain solution A; 5mL of concentrated ammonia water (25wt%) was added to 25mL of absolute ethanol, stirred evenly to obtain solution B; slow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com