Surface membrane coagulation technology and device for efficiently removing fire coal flying ash microspheres

A technology of microbeads and fly ash, applied in the field of air pollutant control, can solve the problems of limited removal efficiency, smoke emission control, poor charging performance, etc., to achieve adhesion and surface energy, efficient removal, surface resistance reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

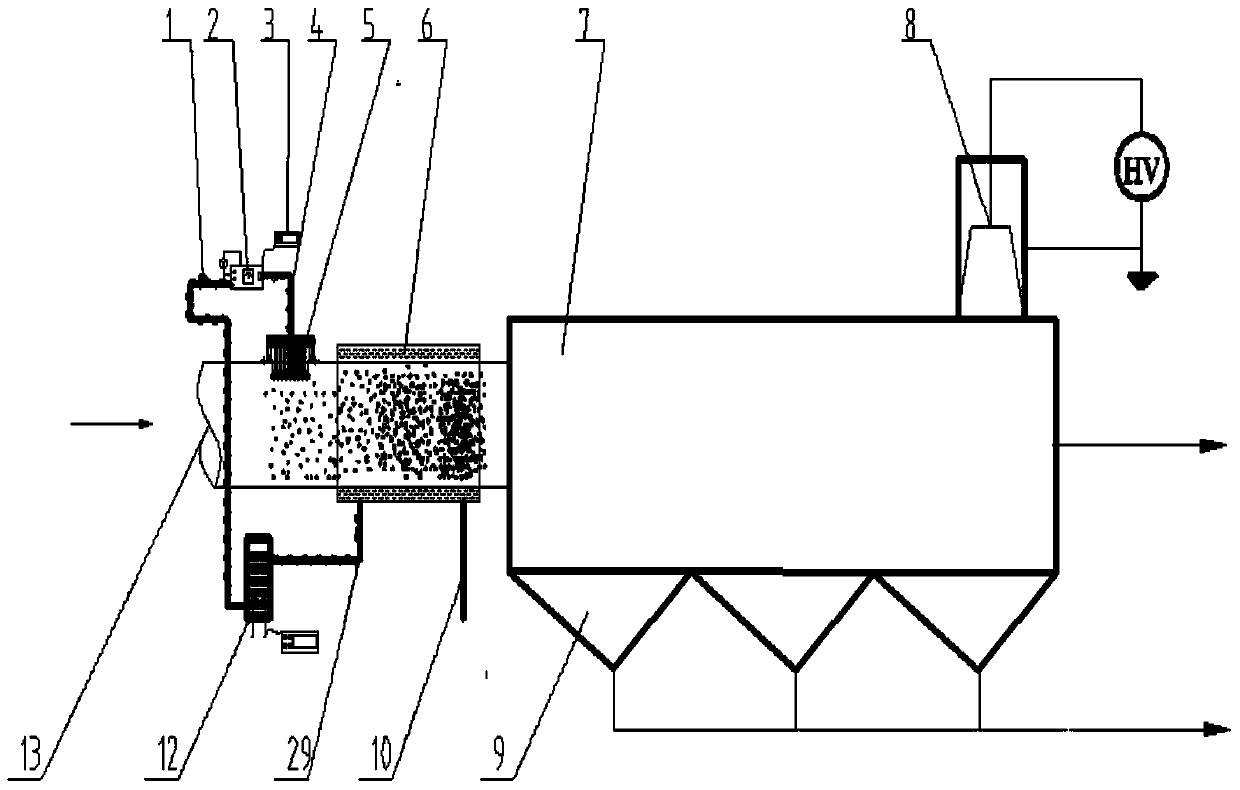

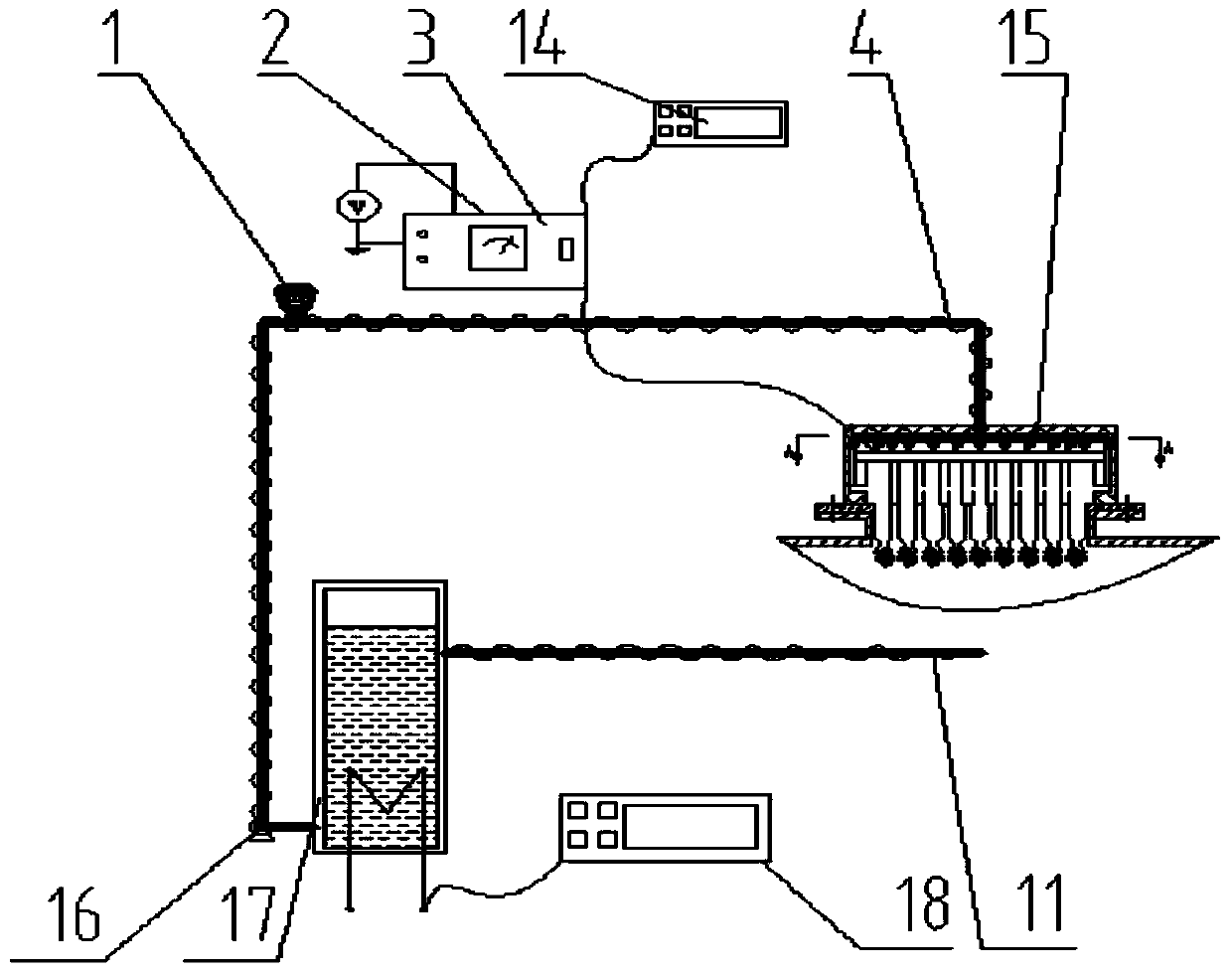

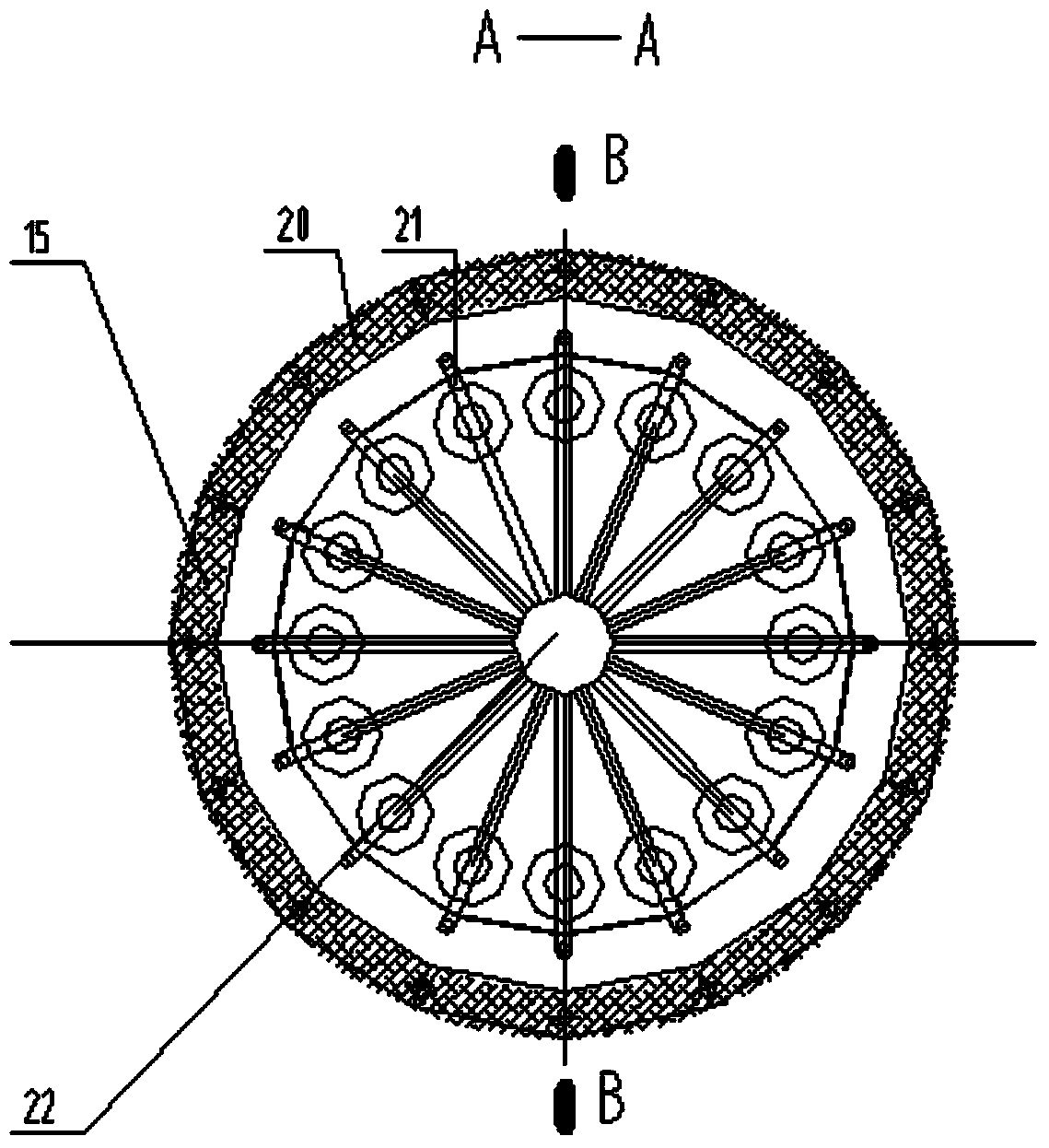

[0017] Combine below figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 A best specific embodiment of the present invention is given.

[0018] As shown in the drawings, the atomization system of the present invention is composed of an electric heating water storage tank 12, a water pump 16, a flow meter 1, an ultrasonic drive power supply 2, a power supply display 3, a heat tracing pipe 4, and a flower plate atomizer 5; The plate type atomizer 5 is composed of an atomizer shell 15, an ultrasonic power regulator 14, an outer insulation cover 20 of the atomizer, an atomizing head 27, an atomizing head water inlet 21, a main water inlet pipe 22, a water inlet branch pipe 23, a pull The Farr outlet pipe 24, the flower plate flange 25, and the flower plate 28 are composed; the flower plate atomizer 5 is placed horizontally, and the flue flange 26 passing through the flower plate flange 25 and the inlet flue 13 in the circumferential direction is connected by bolts; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com