Hexavalent-chromium appearance imitated anti-corrosion membrane plating method

A hexavalent chromium, imitation electroplating technology, applied in chemical instruments and methods, sputtering plating, ion implantation plating, etc. High corrosion resistance and weather resistance, the effect of high weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

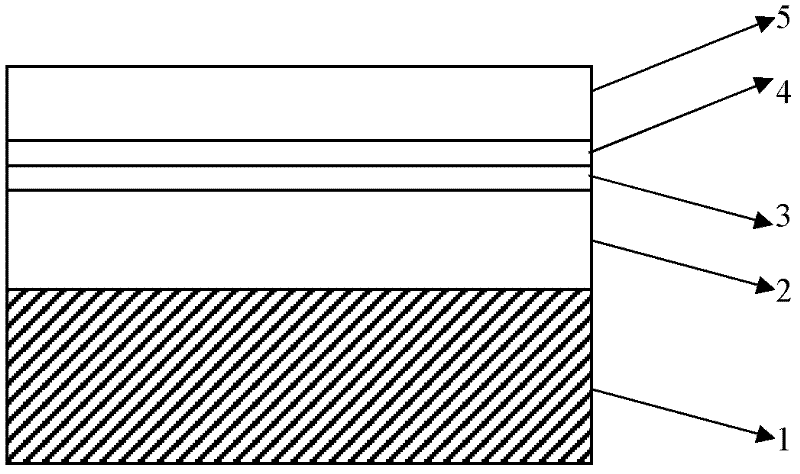

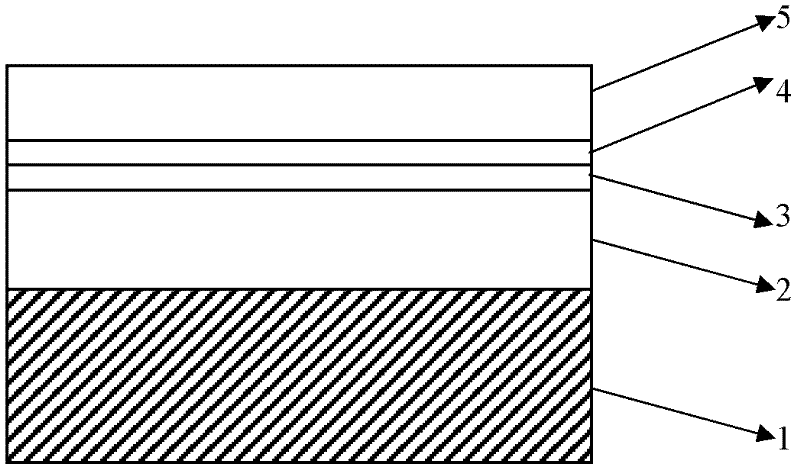

[0022] Example 1 A bright chrome (hexavalent chromium color) for an ABS shower head, see the structural diagram figure 1 .

[0023] Step 1: After the blank 1 obtained by ABS injection molding is wiped with a dry cloth, the hanging product is subjected to flame treatment and electrostatic dust removal through an automatic flame processor and an electrostatic precipitator, and the processing time is 6 seconds.

[0024] Step 2: Then spray a layer of UV paint 2 with a thickness of 25 μm. The paint layer 2 is baked with an IR lamp (60°C×5min), and then cured with a UV lamp (1100J / m 2 ).

[0025] Step 3: Transfer the photocured plastic parts into the PVD furnace for plasma gas activation (conditions are DC bias voltage 3000V, vacuum pressure in the furnace 1Pa, working gas equal ratio of Ar and O at 50SCCM:50SCCM 2 Mixed air flow, activation time is 1min); then 40 nanometers thick aluminum layer 3 is evaporated and plated on the paint surface (the conditions of the aluminum coati...

Embodiment 2

[0034] Embodiment 2 A kind of PC material photo frame bright chrome (hexavalent chromium color), structure diagram sees figure 1 .

[0035] Step 1: After wiping the blank 1 obtained by PC injection molding with a dry cloth, the hanging product is subjected to flame treatment and electrostatic dust removal through an automatic flame processor and an electrostatic precipitator, and the processing time is 6 seconds.

[0036] Step 2: Then spray a layer of UV paint 2 with a thickness of 22 μm. The paint layer 2 is baked with an IR lamp (60°C×5min), and then cured with a UV lamp (1100J / m 2 ).

[0037] Step 3: Transfer the photocured plastic parts into the PVD furnace for plasma gas activation (conditions are DC bias voltage 3000V, vacuum pressure in the furnace 1Pa, working gas equal ratio of Ar and O at 50SCCM:50SCCM 2 Mixed air flow, activation time is 1min); then 40 nanometers thick aluminum layer 3 is evaporated and plated on the paint surface (the conditions of the aluminum ...

Embodiment 3

[0046] Example 3 An example of high-gloss hexavalent chromium at the tuyere of an iron piece, see the structure diagram figure 1

[0047] Step 1: Wipe the tuyere piece 1 punched by the iron piece with a dry cloth first, then perform flame treatment and then electrostatic dust removal, and the flame treatment time is 2 minutes.

[0048] Step 2: Then spray a layer of UV paint 2 with a thickness of 30 μm. The paint layer is heated and leveled by infrared lamps (60℃×5min), and then cured by ultraviolet lamps (1100J / m2 ).

[0049] Step 3: Transfer the primer-sprayed blank into a PVD furnace for plasma gas activation (conditions are DC bias voltage 3000V, furnace vacuum pressure 1Pa, working gas equal ratio of 50SCCM: 50SCCM Ar and O 2 Mixed air flow, activation time is 1min); then 40 nanometers thick aluminum layer 3 is evaporated and plated on the paint surface (the conditions of the aluminum coating layer are evaporation preheating voltage 3.5V for 30s, pre-melting 4.5V for 10s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Binding force | aaaaa | aaaaa |

| Pencil hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com