Smooth LED flexible light bar and device and method for manufacturing same

A technology of LED flexible light strips and equipment, which is applied in the direction of lighting and heating equipment, semiconductor devices of light-emitting elements, printed circuits connected with non-printed electrical components, etc., which can solve the problem of high production cost and investment in production technology of flexible LED light strips. Large size, cumbersome production process and other problems, to achieve the effect of intelligent adjustment and entanglement, reduce equipment investment, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

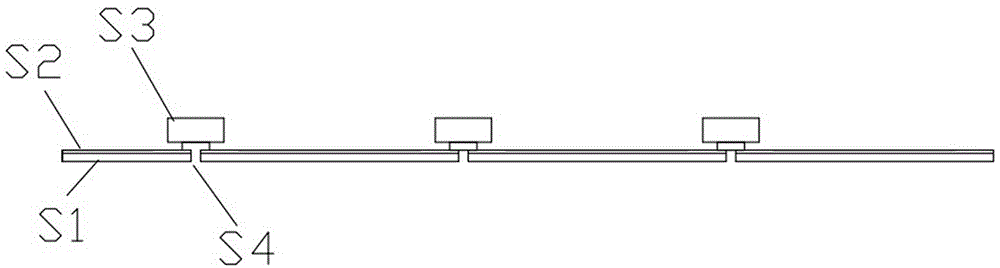

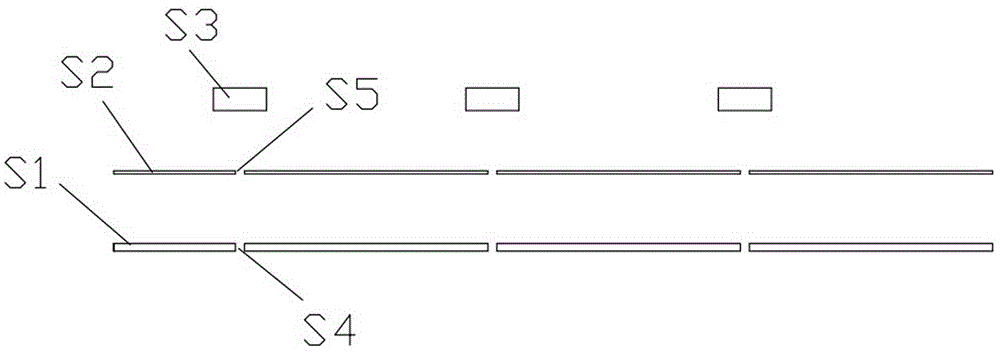

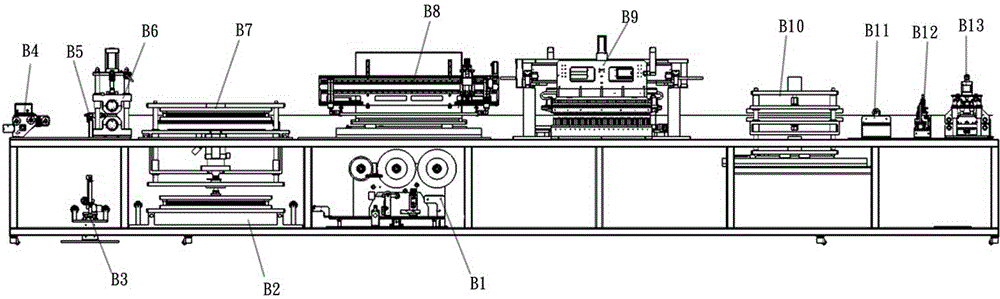

[0067] 1. Examples of implementations of bare LED flexible light strips figure 1 and figure 2 , its specific implementation structure consists of an adhesive auxiliary material layer and a flat conductor bonded on the surface of the adhesive auxiliary material layer. The adhesive auxiliary material layer of this embodiment is a rolled PET film S1, and the flat conductor of this embodiment is a flat copper conductor. S2, the surface of the PET film S1 is tiled with an adhesive layer for bonding the flat copper conductor S2, so that the surface of the PET film S1 is sticky, and the surface of the PET film S1 is punched with an avoidance hole S4, and the surface of the flat copper conductor S2 A cross-section S5 is punched for disconnecting the flat copper conductor S2. The center of the cross-section S5 corresponds to the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com